Resist agent for blue calico

A technology for printed fabrics and anti-staining agents, applied in dyeing, textiles and papermaking, etc., can solve the problems of long processing time, large influence of air humidity, easy falling off of printed products, etc. The effect of high adhesion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

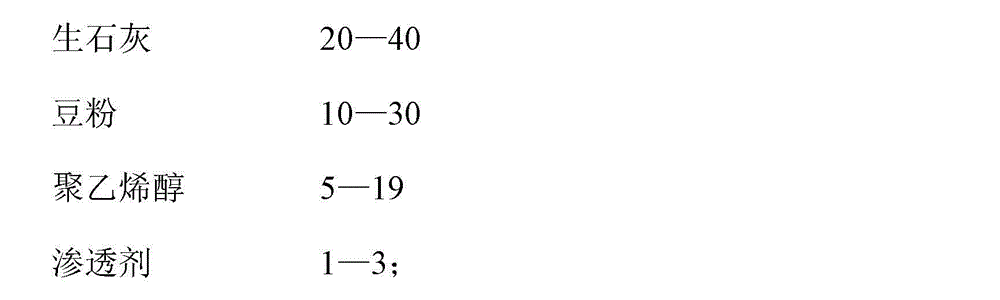

[0019] The anti-dyeing agent for blue calico consists of the following components by weight:

[0020] quicklime 20

[0021] soybean flour 30

[0022] Polyvinyl alcohol 5

[0023] Penetrant 3.

Embodiment 2

[0025] The anti-dyeing agent for blue calico consists of the following components by weight:

[0026] quicklime 40

[0027] soy flour 10

[0028] Polyvinyl alcohol 19

[0029] Penetrant 1.

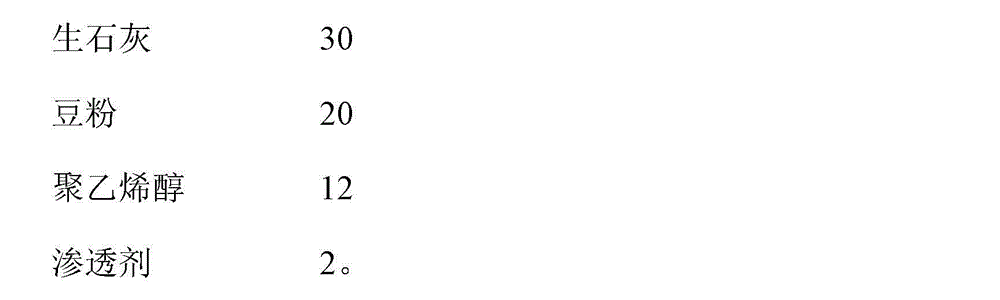

Embodiment 3

[0031] The anti-dyeing agent for blue calico consists of the following components by weight:

[0032] quicklime 30

[0033] soybean flour 20

[0034] Polyvinyl alcohol 12

[0035] Penetrant 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com