Environment-friendly synthesis method of pigment-grade iron oxide red

A technology for iron oxide red and green synthesis, applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve environmental pollution and other problems, and achieve the effect of reducing production costs, low cost, and good pigment performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

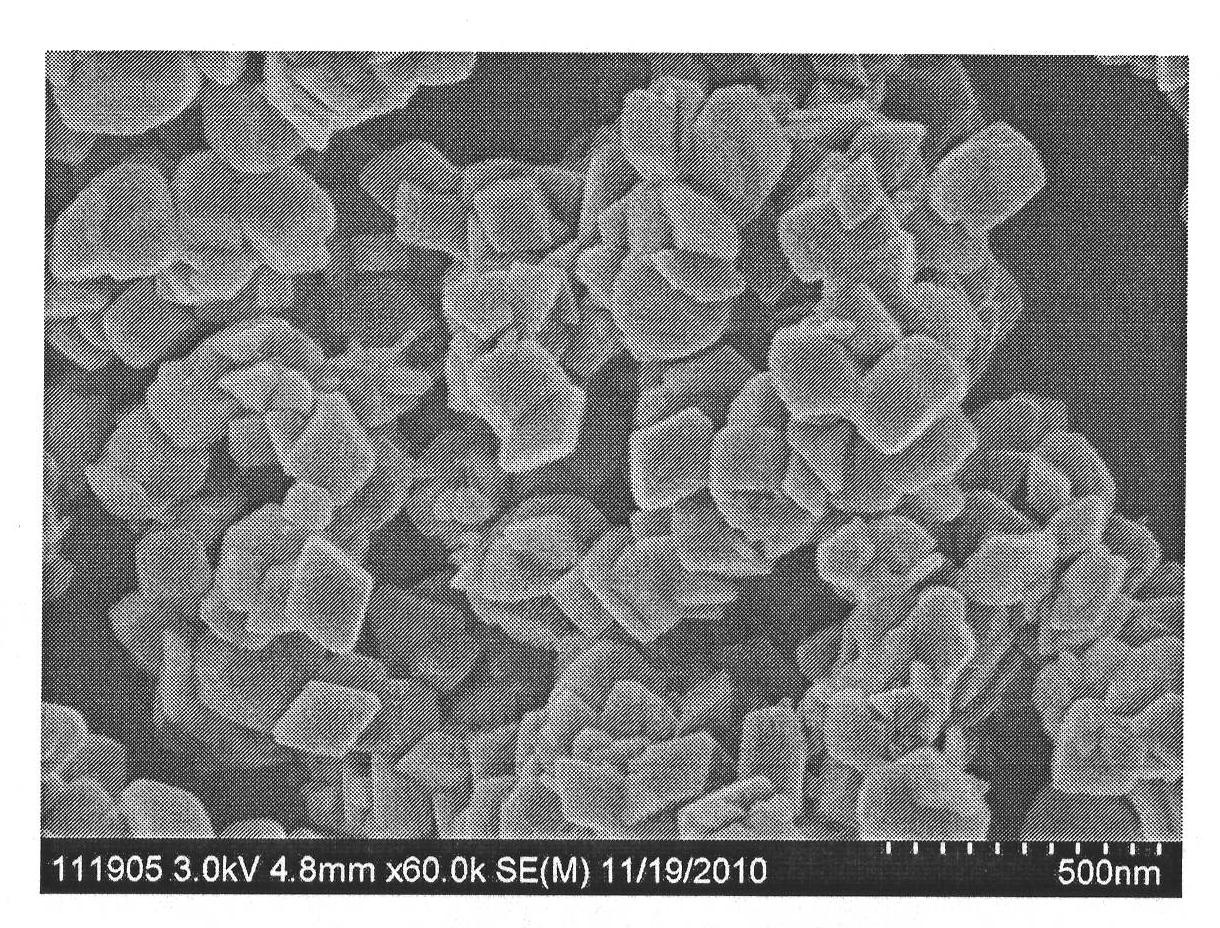

Embodiment 1

[0020] Concentration of 2mol / L Fe(NO 3 ) 3 Solution 50ml, under stirring, use 6.0mol / L NaOH solution to adjust pH = 7, and at the same time, the volume of the resulting suspension is fixed to 200ml to obtain amorphous hydrated iron oxide seeds; transfer the seeds to the reaction In the kettle, the seed crystal concentration is 0.125mol / L, according to the added Fe 2+ The number of moles of ions in the reaction system and the Fe contained in the seed crystal in the reaction system 3+ The ratio of moles of ions is 0.05:1 and ferrous chloride (FeCl 2 ) catalyst, reacted for 0.5h, added 30g excess scrap iron sheet, introduced air, added waste liquid for producing titanium dioxide during the reaction, maintained the concentration of ferrous ions in the reaction system at 0.16mol / L, and maintained the temperature of the reaction system at 90 ℃, reacted for 48h, filtered the product, washed several times with water, and dried to obtain about 23g of the product.

Embodiment 2

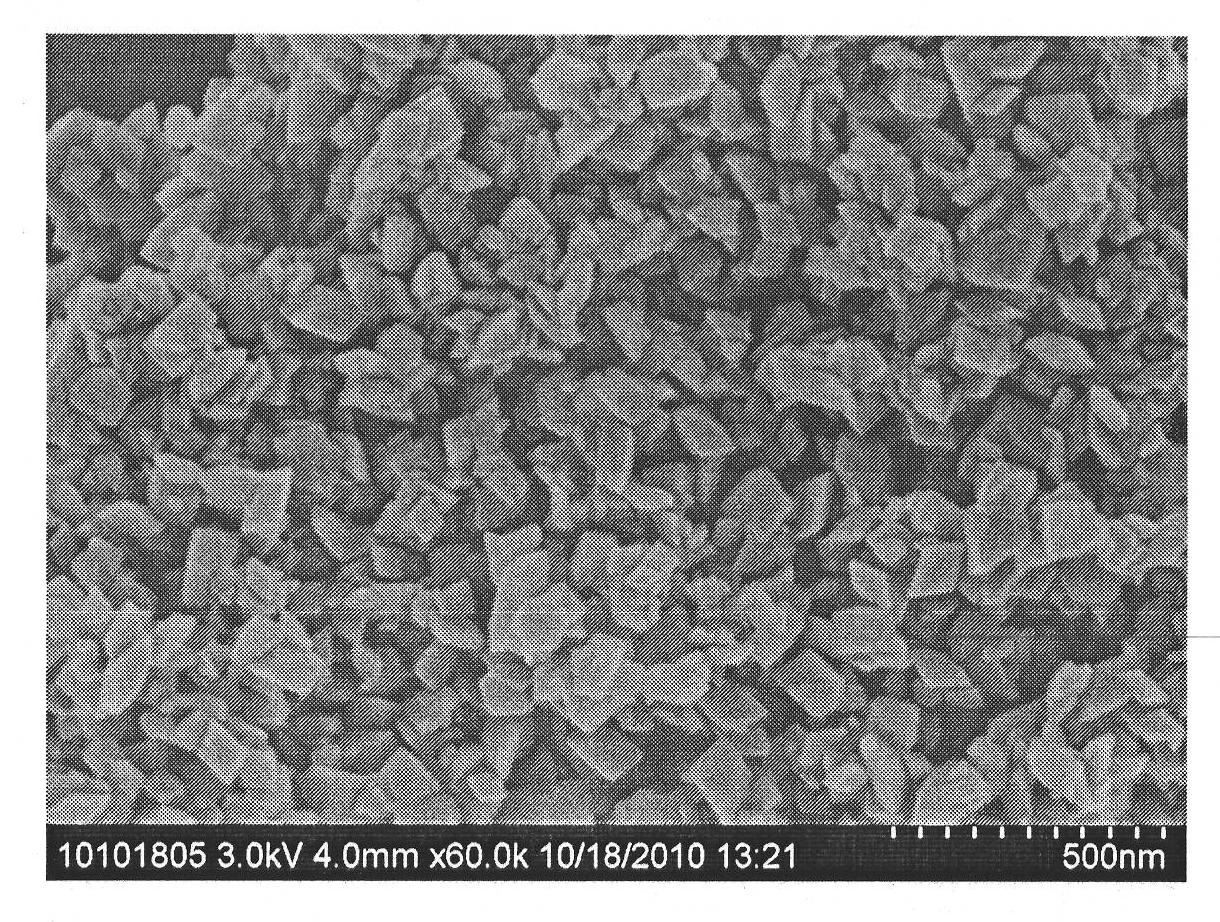

[0022] Concentration of 2mol / L Fe(NO 3 ) 3 Solution 50ml, under stirring, use 6.0mol / L NaOH solution to adjust pH = 7, and at the same time, the volume of the resulting suspension is fixed to 200ml to obtain amorphous hydrated iron oxide seeds; transfer the seeds to the reaction In the kettle, the seed crystal concentration is 0.125mol / L, according to the added Fe 2+ The number of moles of ions in the reaction system and the Fe contained in the seed crystal in the reaction system 3+ The ratio of moles of ions is 0.05:1 and ferrous sulfate (FeSO 4 ) after the catalyzer, reacted for 0.5h, added 30g excess scrap iron sheet, passed into air, added ferrous salt (waste liquid for producing titanium dioxide) in the reaction process, maintained the concentration of ferrous ion in the reaction system to be 0.16mol / L, and reacted The temperature of the system was maintained at 90°C, and the reaction was carried out for 48 hours. The product was filtered, washed several times with wat...

Embodiment 3

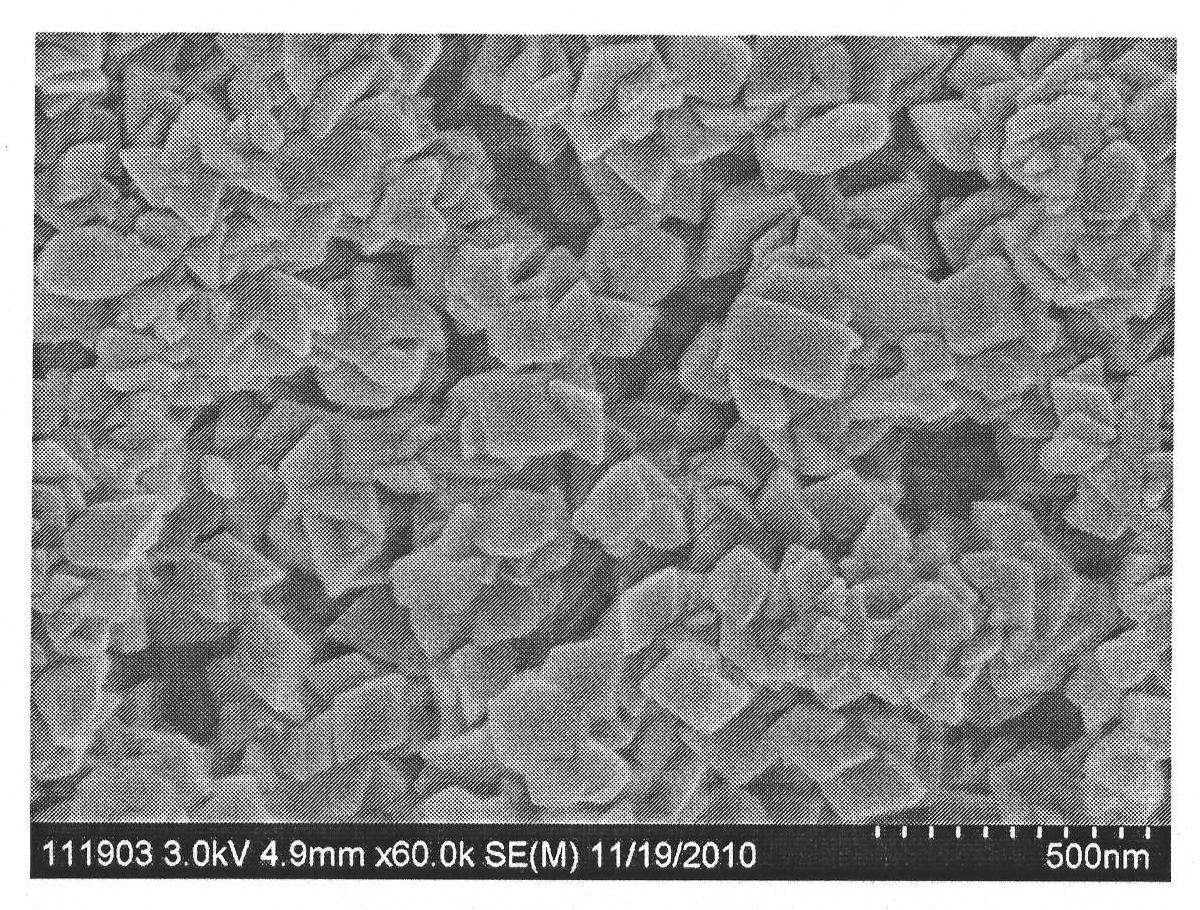

[0024] Concentration of 2mol / L Fe(NO 3 ) 3 Solution 50ml, under stirring, use 6.0mol / L NaOH solution to adjust pH = 7, and at the same time, the volume of the resulting suspension is fixed to 200ml to obtain amorphous hydrated iron oxide seeds; transfer the seeds to the reaction In the kettle, the seed crystal concentration is 0.125mol / L, according to the added Fe 2+ The number of moles of ions in the reaction system and the Fe contained in the seed crystal in the reaction system 3+ The ratio of moles of ions is 0.05:1 and ferrous chloride (FeCl 2 ) after the catalyzer, reacted for 0.5h, added 30g excess scrap iron sheet, passed into air, added ferrous salt (waste liquid for producing titanium dioxide) in the reaction process, maintained the concentration of ferrous ion in the reaction system as 0.20mol / L, reacted The temperature of the system was maintained at 90°C, and the reaction was carried out for 48 hours. The product was filtered, washed several times with water, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com