Nano zinc metastannate air-sensitive material with hollow fiber structure and preparation method thereof

A technology of nano-zinc metastannate and fiber structure, which is applied in the field of sensing materials, can solve the problems of gas-sensing materials without hollow structure, small specific surface area, and limited gas sensitivity, so as to facilitate adsorption and desorption, preparation The method is simple and the effect of good sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of hollow fiber structure nano-zinc metastannate gas sensitive material comprises the above steps:

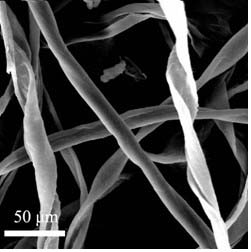

[0025] 1) Pretreatment of the absorbent cotton fiber biological template: rinse the absorbent cotton balls with deionized water and absolute ethanol repeatedly, dry them, and pull them loosely;

[0026] 2) The configuration of the mixed solution of zinc nitrate and tin tetrachloride: the concentration is 0.2 mol / L, and the solute is soluble SnCl 4 ·5H 2 O and Zn(NO 3 ) 2 ·6H 2 O, the two molar ratios are 1:1, and the solvent is deionized water;

[0027] 3) The pretreated absorbent cotton fibers are soaked in the mixed solution for 24 hours, then taken out and put into a drying oven to dry;

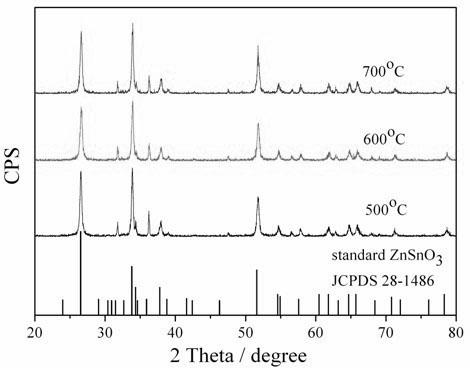

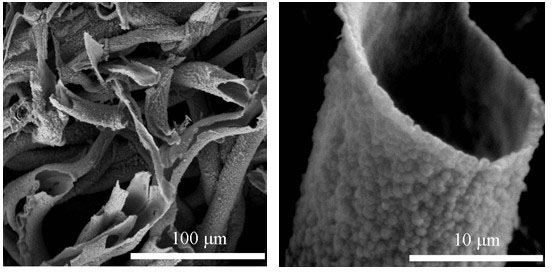

[0028] 4) Put the cotton fiber obtained in step 3) into a muffle furnace, raise the temperature to 500°C at a rate of 1°C / min, keep it warm for 3 hours, then stop heating, and take out the burnt product after the furnace temperature is naturally cooled to ...

Embodiment 2

[0036] The preparation method of hollow fiber structure nano-zinc metastannate gas sensitive material comprises the above steps:

[0037]1) Pretreatment of the absorbent cotton fiber biological template: rinse the absorbent cotton balls with deionized water and absolute ethanol repeatedly, dry them, and pull them loosely;

[0038] 2) The configuration of the mixed solution of zinc chloride and tin tetrachloride: the concentration is 0.2 mol / L, the molar ratio of the two is 1:1, and the solvent is deionized water;

[0039] 3) The pretreated absorbent cotton fibers are soaked in the mixed solution for 48 hours, then taken out and put into a drying oven to dry;

[0040] 4) Put the cotton fiber obtained in step 3) into a muffle furnace, heat up to 600°C at a heating rate of 3°C / min, keep it warm for 3 hours, then stop heating, and take out the burnt product after the furnace temperature is naturally cooled to room temperature, and you can get Zinc metastannate gas sensitive mater...

Embodiment 3

[0048] The preparation method of hollow fiber structure nano-zinc metastannate gas sensitive material comprises the above steps:

[0049] 1) Pretreatment of the absorbent cotton fiber biological template: rinse the absorbent cotton balls with deionized water and absolute ethanol repeatedly, dry them, and pull them loosely;

[0050] 2) The configuration of the mixed solution of zinc chloride and tin dichloride: the concentration is 0.5 mol / L, the molar ratio of the two is 1:1, and the solvent is deionized water;

[0051] 3) The pretreated absorbent cotton fibers are soaked in the mixed solution for 12 hours, then taken out and placed in a drying oven to dry;

[0052] 4) Put the cotton fiber obtained in step 3) into a muffle furnace, heat up to 700°C at a heating rate of 5°C / min, keep it warm for 3 hours, then stop heating, and take out the burnt product after the furnace temperature is naturally cooled to room temperature, and you can get Zinc metastannate gas sensitive materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com