Method for finely grinding and separating fine grain iron ore

A technology for fine-grained iron ore, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problem that it is difficult to achieve fine-grained mineral refinement and dissociation, ordinary horizontal ball mills cannot obtain satisfactory results, and minerals are easy to It can improve the efficiency of energy utilization, improve the degree of monomer dissociation, and simplify the equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

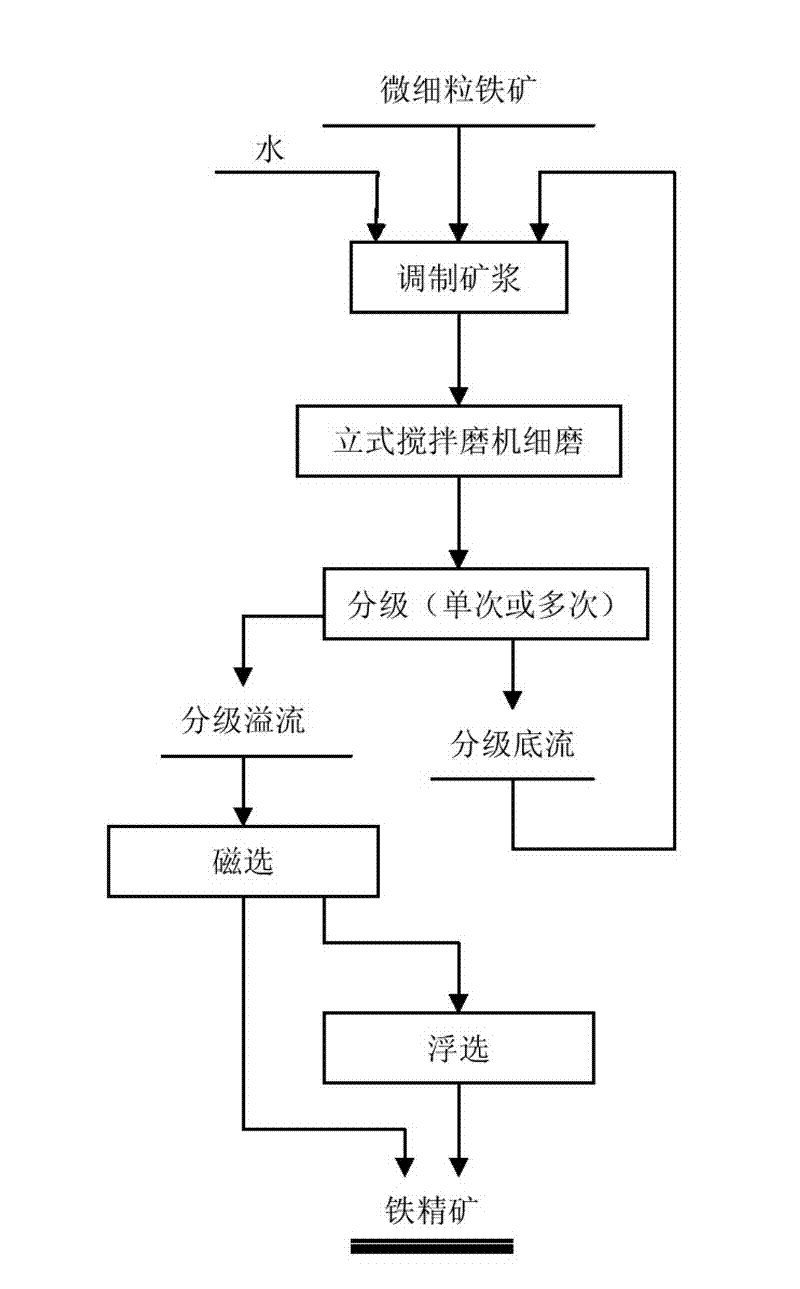

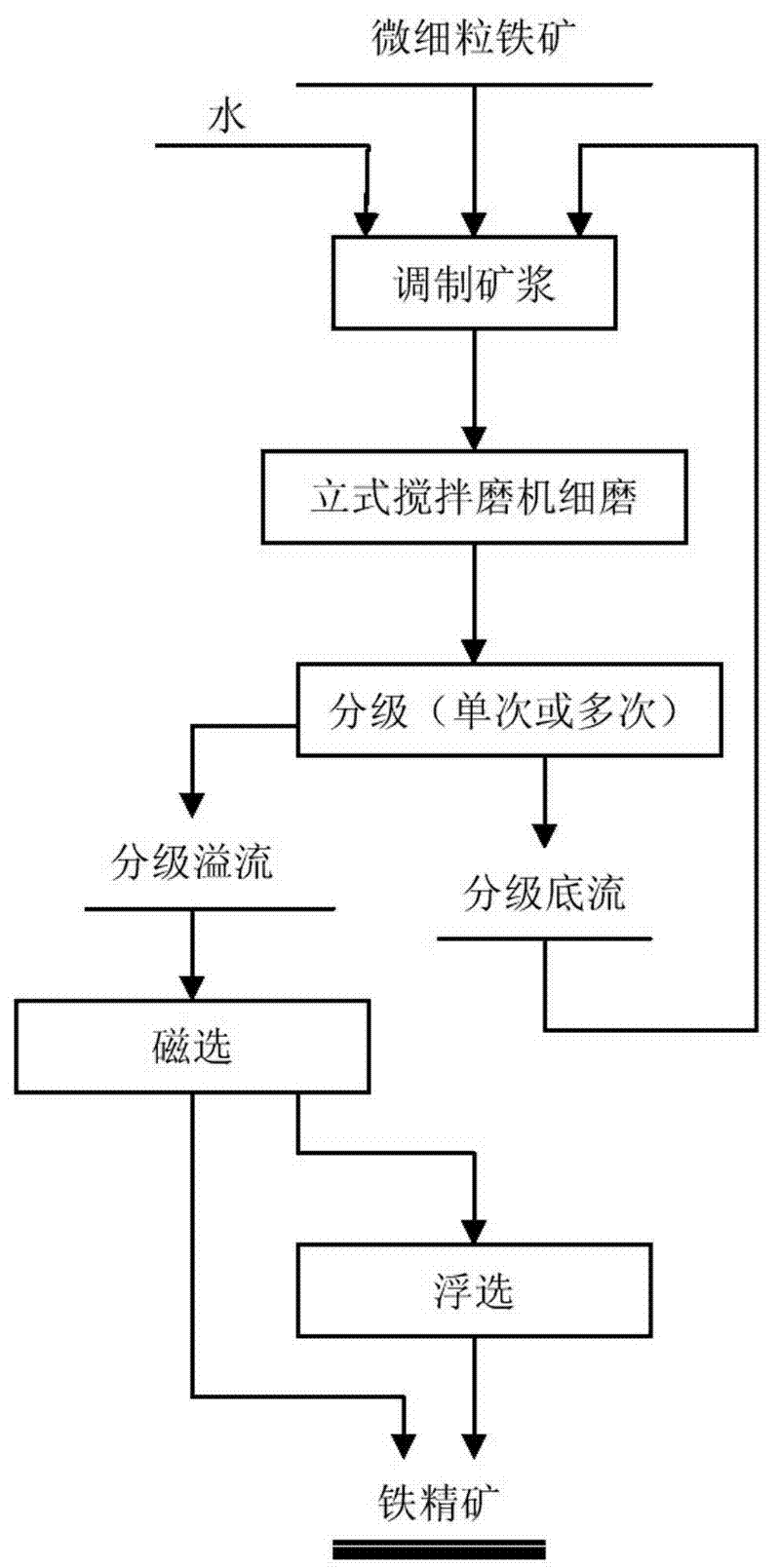

[0015] a kind of like figure 1 The fine grinding and sorting method of the fine-grained iron ore of the present invention as shown comprises the following steps: first, a certain fine-grained iron ore in Hunan (it is a mixed ore of magnetite and hematite, and magnetite is used as Main) rough concentrate (the iron grade of the rough concentrate is 36%, particle size D 80 84μm) mixed with water to make a pulp with a mass concentration of 60%, and the pulp flows into the vertical stirring mill (the vertical stirring mill uses a rod stirrer) through the feeder (or high-level tank, etc.) for vertical grinding The fine grinding of the vertical stirring mill, the vertical stirring mill is filled with steel balls with a diameter of 6mm to 12mm, the filling amount is 2 / 3 of the cylinder volume of the vertical stirring mill, and the rotating speed of the vertical stirring mill is controlled at 250r / min, the discharged material is stirred evenly and pumped into the hydrocyclone for clas...

Embodiment 2

[0017] a kind of like figure 1 The fine grinding and sorting method of the fine grained iron ore of the present invention as shown, comprises the following steps: first, the anti-floating tailings (the anti-floating tailings) of a certain micro-fine iron ore (which is mainly magnetite) in Baotou Grade 29%, particle size D 80 100μm) mixed with water to make a slurry with a mass concentration of 65%, the slurry flows into the vertical stirring mill (the vertical stirring mill uses a disc agitator) through the high-level tank for fine grinding, and the mill is filled with 20mm ~30mm steel balls, the filling amount is 2 / 3 of the cylinder volume of the vertical stirring mill, the rotating speed of the vertical stirring mill is controlled at 400r / min, and the output is pumped into the hydrocyclone for classification, classification After the underflow and the pulp are combined, the fine grinding of the vertical mixer is carried out again, and the classification overflow is used as ...

Embodiment 3

[0019] a kind of like figure 1 The fine grinding and sorting method of the fine-grained iron ore of the present invention as shown, comprises the following steps: first, a certain fine-grained embedded iron ore in Xinjiang (it is the mixed ore of magnetite and hematite, and with magnetite Ore-based) coarse concentrate (grain size D 80 60μm) to make a slurry with a mass concentration of 65%, pump the slurry into a vertical stirring mill (the agitator of the vertical stirring mill uses a spiral agitator) for fine grinding, and fill the vertical stirring mill with 15mm ~25mm steel balls, the filling amount is 2 / 3 of the cylinder volume of the vertical agitating mill, the speed of the vertical agitating ball mill is controlled at 120r / min, the discharged material is stirred evenly, and pumped into the centrifugal classifier for classification, After the grading underflow is merged with the pulp, it will be put into the vertical stirring mill again, and the grading overflow will e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com