Dust collection barrel of dust collector with automatically cleaned filter

An automatic cleaning and filter technology, which is applied in the direction of cleaning filter devices, suction filters, brushes, etc., can solve the problems of difficult to clean, difficult to clean, and clogged filter holes, so as to improve dust removal efficiency, keep clean, The effect of ensuring ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below with reference to the drawings and examples. The same symbols are used for the same components in the present invention as in the prior art.

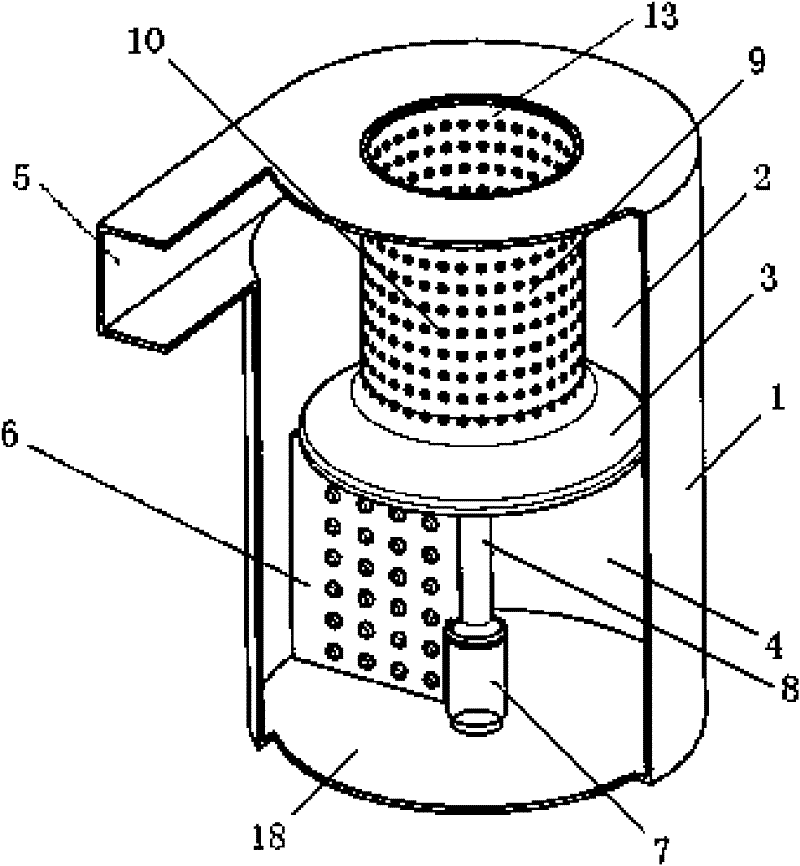

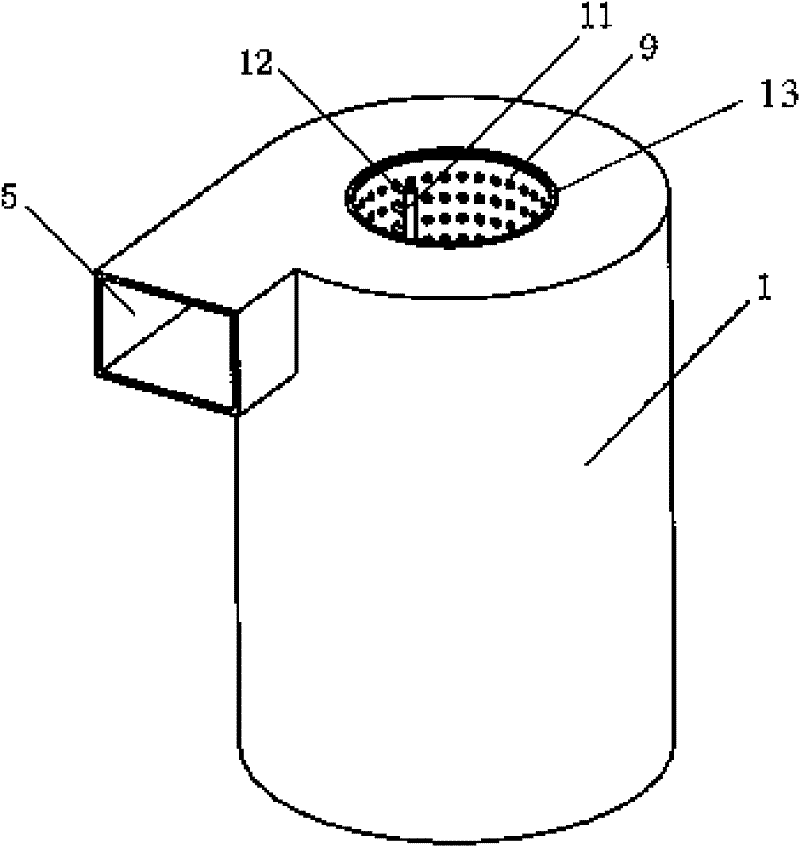

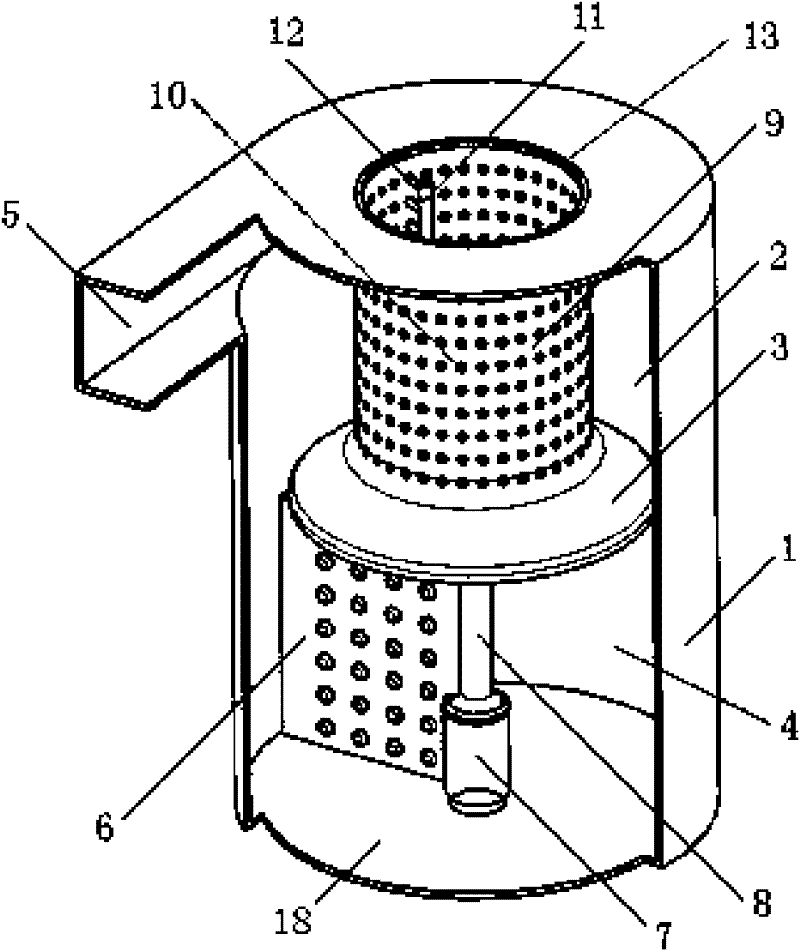

[0040] The vacuum cleaner dust collecting barrel of (of) automatic cleaning filter of the present invention, as Figure 2 to Figure 7 as shown, figure 2 It is a perspective view of the appearance of the dust collecting bucket of the vacuum cleaner of the present invention; image 3 It is a partly cut-away internal structure diagram of the dust collecting bucket of the vacuum cleaner of the present invention; Figure 4 It is a top view of the dust bucket of the vacuum cleaner of the present invention; Figure 5 Yes Figure 4 The A-A profile; Image 6 It is an assembly drawing of the bristle bracket of the dust collecting barrel of the vacuum cleaner of the present invention; Figure 7 It is an exploded view of the assembly structure of the bristle bracket of the dust c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com