Multilevel processing method for regenerating acid base from glutamic acid isoelectric mother liquor

A treatment method, glutamic acid technology, applied in electrodialysis, food preparation, food science, etc., to achieve the effect of improving current efficiency, increasing concentration, and alleviating H+ leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] The bipolar membrane electrodialysis process for regenerating acid-base from glutamic acid isoelectric mother liquor is divided into three stages, using three independently operated three-chamber bipolar membrane electrodialyzers, each as a first stage, see Figure 6 . Identical to every three-compartment bipolar membrane electrodialyzer, see Figure 4 . The direction of liquid flow in adjacent compartments is co-current. The area of the ion exchange membrane is 210mm×62mm, using BP-1 type bipolar membrane, JAM-10 type anion exchange membrane and JCM-1 type cation exchange membrane. Bipolar membrane, anion exchange membrane, and cation exchange membrane form a three-compartment membrane stack structure (such as Figure 4 ) Repeat for 5 pairs. Each set is equipped with a pair of electrodes, a titanium electrode coated with ruthenium is used as the anode plate, and a stainless steel electrode is used as the cathode plate. Both the partition and the net are polyprop...

Embodiment 2

[0081] The bipolar membrane electrodialysis process for regenerating acid-base from glutamic acid isoelectric mother liquor is divided into three stages, using three independently operated three-chamber bipolar membrane electrodialyzers, each as a first stage, see Figure 6 . The three-chamber bipolar membrane electrodialyzer is the same as in Example 1.

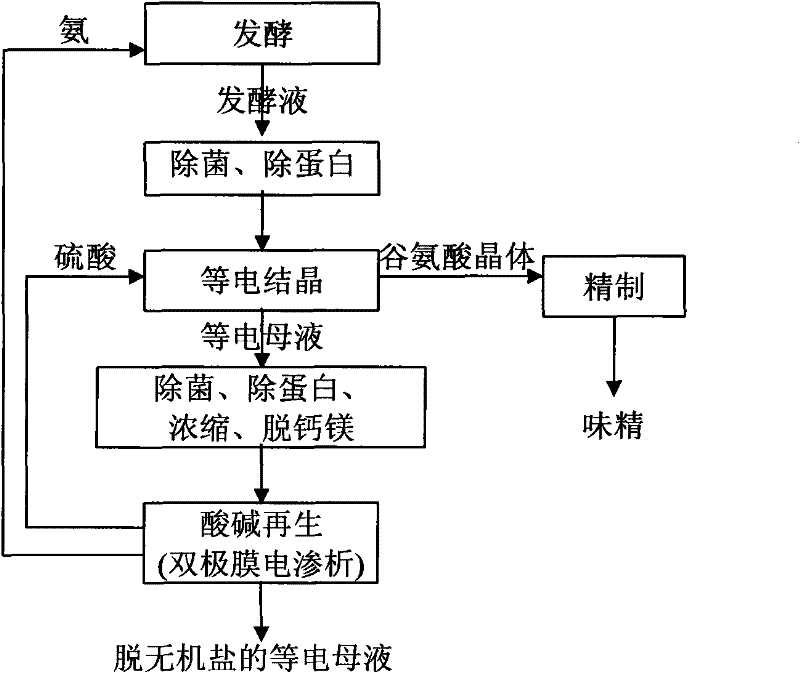

[0082] See image 3 .

[0083] Bacteria removal and protein removal: Filtrate the mother liquid of glutamic acid and other electricity through the 0.2μm microfiltration membrane and 3K ultrafiltration membrane module of Tianjin Motianmo Engineering Technology Co., Ltd. to obtain about 6 liters of clear liquid containing 34g / L ammonium chloride , 17g / L glutamic acid.

[0084] The salt chamber of the first-stage electrodialyzer is fed with 5.8 L of electrolytic mother liquid such as glutamic acid that has been sterilized and protein-removed, and the acid chamber is fed with the second hydrochloric acid concentration of 1.8 ...

Embodiment 3

[0089] The bipolar membrane electrodialysis process for regenerating acid-base from glutamic acid isoelectric mother liquor is divided into three stages, using three independently operated three-chamber bipolar membrane electrodialyzers, each as a first stage, see Figure 8 . Bipolar membrane electrodialyzer is the same as embodiment 1.

[0090] See image 3 .

[0091] Bacteria removal and protein removal: Filtrate the mother liquid of glutamic acid and other electricity through the 0.2μm microfiltration membrane and 10K ultrafiltration membrane module of Tianjin Motianmo Engineering Technology Co., Ltd. to obtain about 6 liters of clear liquid, containing 51g / L ammonium nitrate, 19g / L glutamic acid.

[0092] Concentrating the isoelectric mother liquor: heating and concentrating the clear liquid of the above-mentioned glutamic acid isoelectric mother liquor by 2 times.

[0093] Decalcification of magnesium ions: Add 0.05 mol / L oxalic acid to the above-mentioned concentrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy consumption | aaaaa | aaaaa |

| Energy consumption | aaaaa | aaaaa |

| Energy consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com