Nutrient noodle and preparation method thereof

A technology for pasta and nutrition, applied in the field of food product processing, can solve the problems of reduced taste, damage to health, easy leakage and falling, etc., and achieve the effects of comprehensive nutritional components, convenient carrying and high observability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

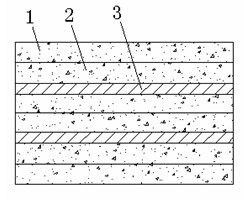

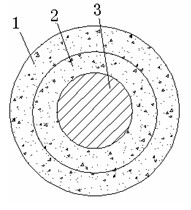

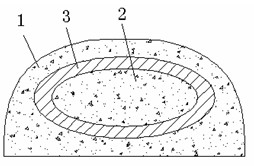

Image

Examples

Embodiment 1

[0057] The nutritious pasta provided by the invention is through the following steps:

[0058] A, carry out raw material preparation of coarse miscellaneous grain flour and fine grain flour according to the following mass ratio:

[0059] 400g wheat flour

[0060] 200g corn flour

[0061] 150g pumpkin powder

[0062] 50g soybean flour

[0063] 100g sweet potato flour

[0064] Buckwheat flour 50g

[0065] 50g peanut powder

[0066] B. After mixing the corn flour in step A with melon flour, bean flour, potato flour, buckwheat flour and peanut flour, add 12 grams of milk powder according to 2% of the mass of the mixed flour and mix evenly; in the wheat flour and the mixed flour respectively, press Add yeast and water in a conventional amount to mix, knead into a dough, and ferment for 30 minutes in a conventional manner to obtain wheat dough and coarse grain dough respectively, and roll them into wheat flour and coarse grain slices as usual for later use;

[0067] C. Carry ...

Embodiment 2

[0077] The nutritious pasta provided by the invention is through the following steps:

[0078] A, carry out raw material preparation of coarse miscellaneous grain flour and fine grain flour according to the following mass ratio:

[0079] 500g wheat flour

[0080] 200g corn flour

[0081] Winter melon powder 100g

[0082] 50g pea flour

[0083] Potato flour 50g

[0084] Buckwheat flour 50g

[0085] 50g peanut powder

[0086] B. After mixing the corn flour in step A with melon flour, bean flour, potato flour, buckwheat flour and peanut flour, add 25 grams of milk powder according to 5% of the mass of the mixed flour and mix evenly; in the wheat flour and the mixed flour respectively, press Add yeast and water in a conventional amount to mix, knead into dough, and ferment conventionally for 20 minutes to obtain wheat dough and coarse grain dough respectively, and roll them into wheat flour and coarse grain slices as usual for later use;

[0087] C. Carry out the mixing of ...

Embodiment 3

[0097] The nutritious pasta provided by the invention is through the following steps:

[0098] A, carry out the mixing of coarse miscellaneous grain powder and fine grain powder according to following mass ratio:

[0099] 400 g wheat flour

[0100] Cornmeal 200 g

[0101] Cucurbit Gourd Powder 150 g

[0102] Red bean powder 70 g

[0103] Yam powder 70 g

[0104] Buckwheat flour 60 g

[0105] Peanut powder 50 g

[0106] B. After mixing the corn flour in step A with melon flour, bean flour, potato flour, buckwheat flour, and peanut flour, add 18 grams of milk powder according to 3% of the mass of the mixed flour and mix evenly; respectively in the wheat flour and the mixed flour, press Add yeast and water in a conventional amount to mix, knead into a dough, and ferment for 35 minutes in a conventional manner to obtain wheat dough and coarse grain dough respectively, and roll them into wheat flour sheets and extrude into coarse grain strips as usual for later use;

[0107]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com