Three dimensional semiconductor device, method of manufacturing the same and electrical cutoff method for using fuse pattern of the same

一种半导体、保险丝的技术,应用在三维半导体装置领域,能够解决无法重新使用芯片或封装、不可能修好三维半导体装置、经济损失等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

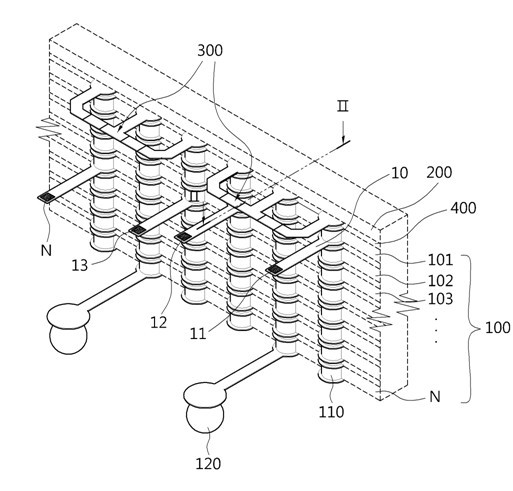

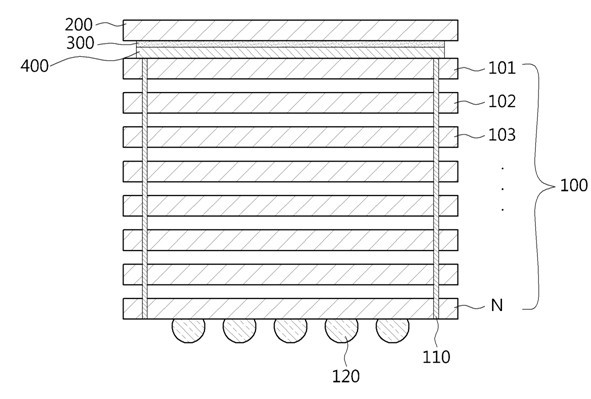

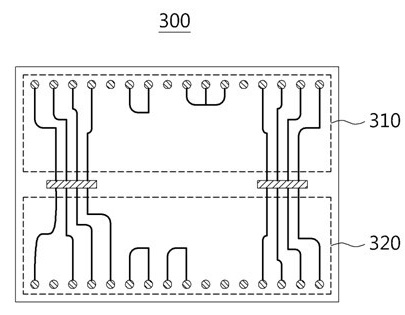

[0025] The advantages and features of the present invention and the methods for achieving these objects will be more clearly understood with reference to the following exemplary embodiments described with accompanying drawings. This invention may, however, be embodied in many different forms and should not be construed as limited to the illustrative embodiments set forth herein. Of course, these exemplary embodiments are provided to make the present disclosure more thorough, and enable those skilled in the art to fully embody and realize the present invention. The scope of application of the invention is defined by the appended claims. Each component is assigned the same reference number throughout the drawings.

[0026] Hereinafter, a three-dimensional semiconductor device, a manufacturing method thereof, and a power cutoff method using a fuse pattern thereof according to exemplary embodiments of the present invention will be described in detail with reference to the accompa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com