Structure design method of free curved surface lens for outdoor LED (light-emitting diode) illumination

A technology of LED lighting and curved lens, applied in lighting and heating equipment, components of lighting devices, lighting devices, etc., can solve problems such as glare effect, low uniformity of illumination, and reduced brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

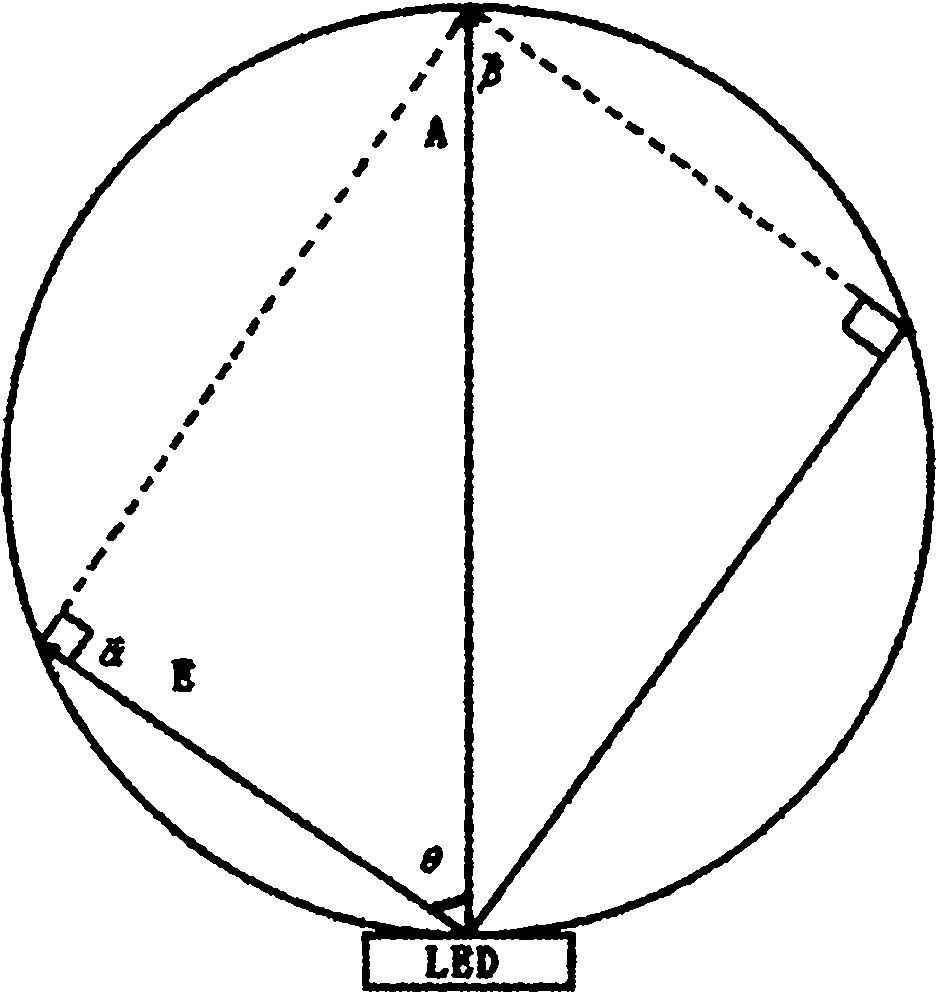

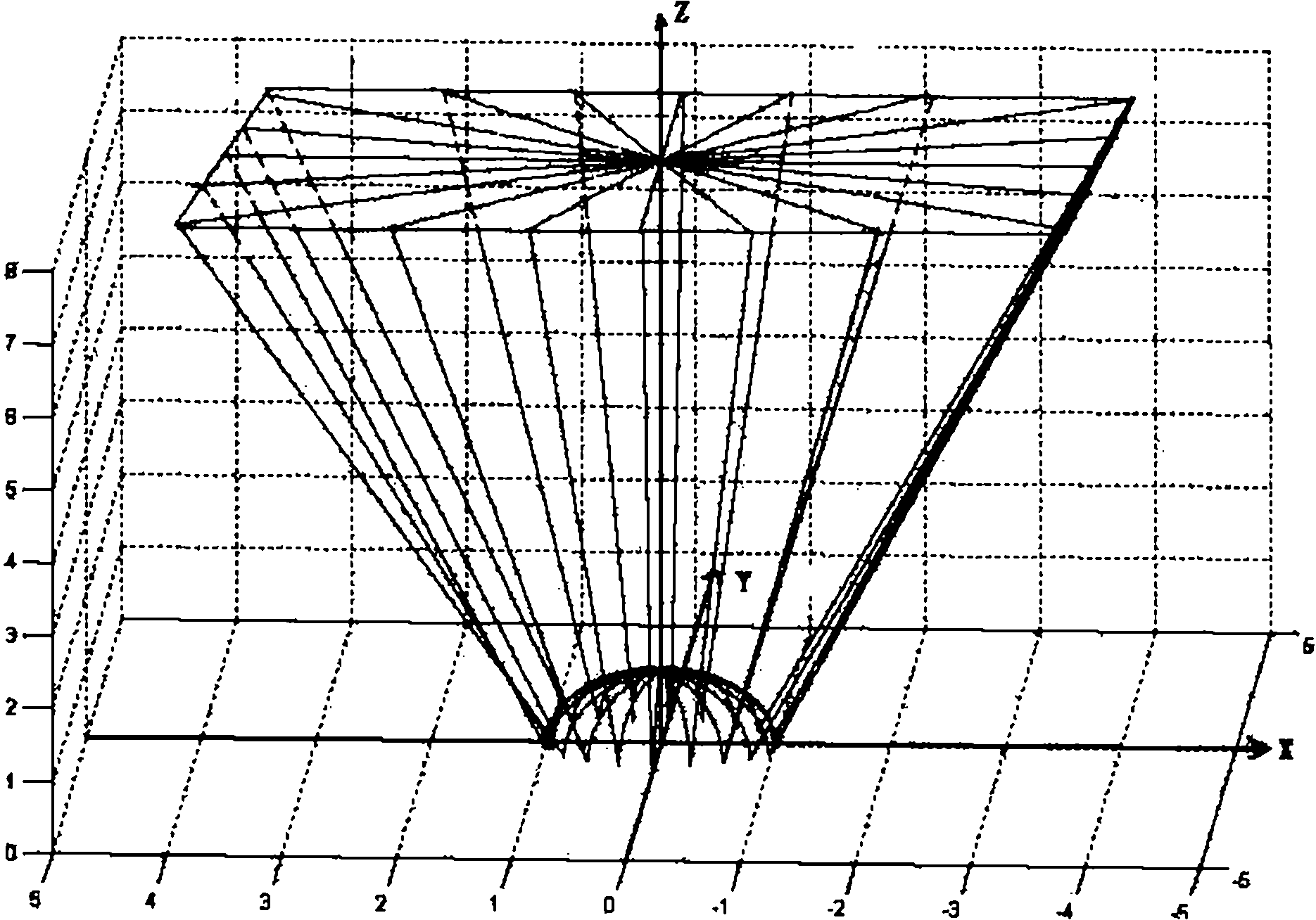

Image

Examples

Embodiment 1

[0083] Suppose the length of the road is 40m, the height of the street lamp is 10m, and the width of the road is 10m. The street lamp is facing the center of the rectangular road surface. The refractive index of the lamp is taken as n=1.5, and the corresponding free-form surface is designed:

[0084] In MATLAB for:

[0085] 1 ρ ( θ ) · dρ ( θ ) = sin θ · g ( θ ) + cos θ cos θ · g ( θ ) - sin θ · dθ - - - ...

Embodiment 2

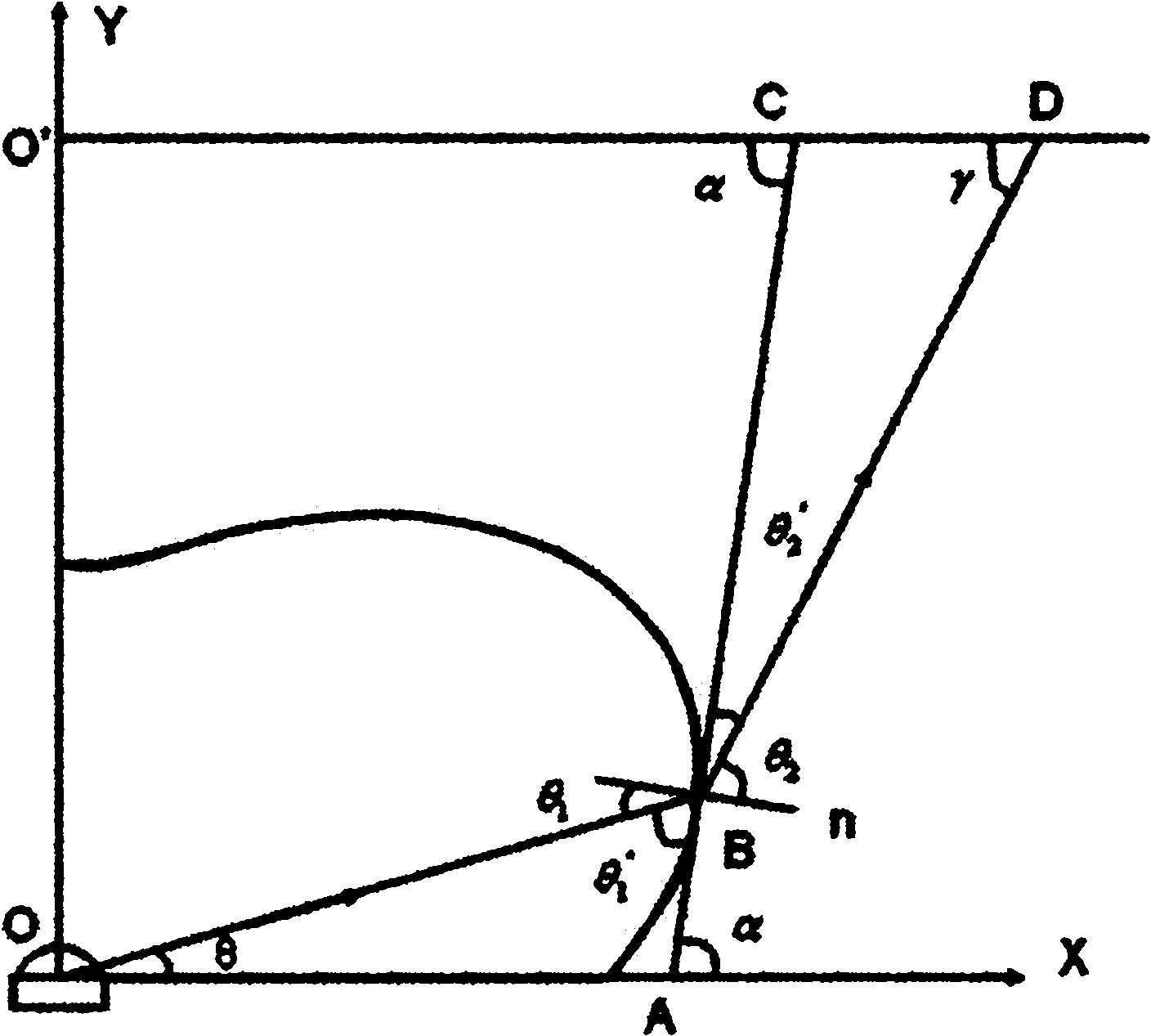

[0091] The road surface is 38m long and 11m wide. The street lamps protrude from the road surface by 1m at an inclination angle of 15°. The refractive index of the material is n=1.5. The schematic diagram of engineering requirements is as follows ( Figure 5 ):

[0092] The profile of the quadratic light distribution surface is given as Image 6 :

[0093] The outer curve b is the direction along the length of the road surface In the profile, the profile curve of the secondary light distribution surface of the lamp;

[0094] The inner curve a is along the road width direction In the profile, the profile curve of the secondary light distribution surface of the lamp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com