Directly-lit LED backlight module and liquid crystal display

A backlight module, direct type technology, applied in the field of direct type LED backlight modules and liquid crystal displays, can solve the problems of poor brightness and color coordinate consistency, and achieve the effects of simplifying the production process, avoiding absorption, and saving packaging costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

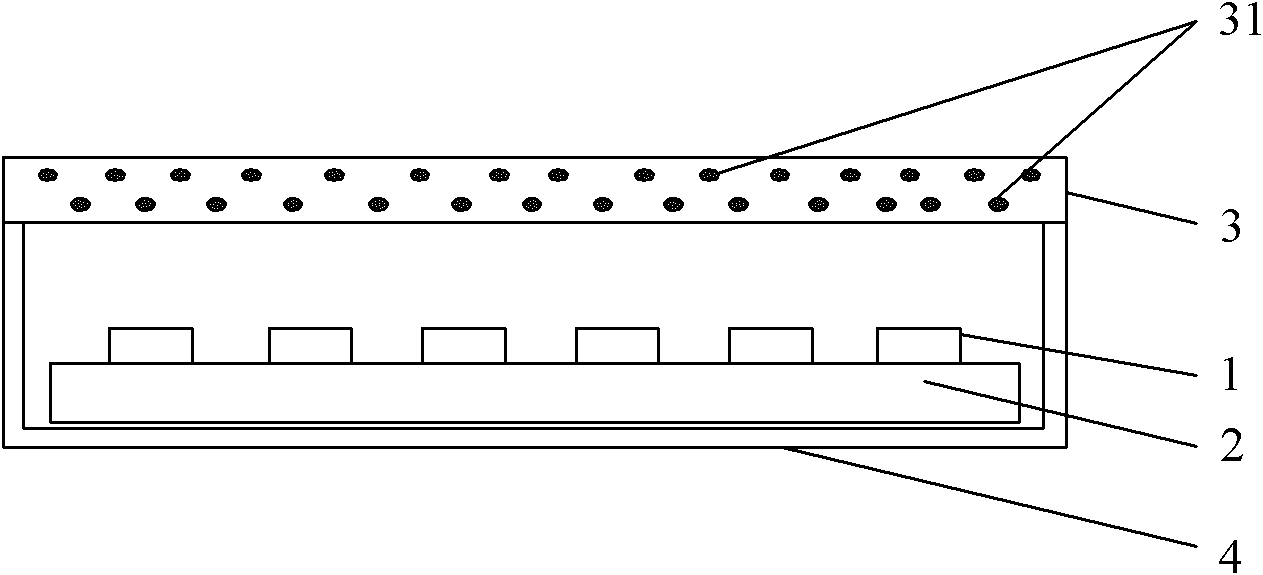

[0015] figure 1 A schematic structural view of the direct-lit LED backlight module provided by the first embodiment of the present invention is shown, and for convenience of description, only parts related to this embodiment are shown.

[0016] The direct-lit LED backlight module includes an LED chip 1 and a printed circuit board 2 , the LED chip 1 is arranged on the front of the printed circuit board 2 , and emits light by being electrically connected with the printed circuit board 2 . Wherein, the LED chip 1 is a bare chip, and the outside is not packaged with fluorescent glue. A light guide plate 3 with high light transmittance is provided in the light emitting direction of the LED chip 1 , and the light guide plate 3 contains uniformly distributed fluorescent excitation substances 31 . The excitation light emitted by the LED chip 1 enters the light guide plate 3 to excite the fluorescent excitation substance 31 to make it emit fluorescence, and the fluorescence and the ex...

Embodiment 2

[0024] In this embodiment, the light guide plate 3 can be further improved so that it can atomize the light. In this way, the light emitting surface of the light guide plate becomes a surface light source with uniform light intensity, which is beneficial to improve the uniformity of the brightness of the display panel. Specifically, the light guide plate can adopt the structure of a diffusion plate in a traditional backlight module, and the difference from the traditional diffusion plate is that the light guide plate in this embodiment is a diffusion plate uniformly distributed with fluorescent excitation substances.

[0025] The light guide plate described in this embodiment not only solves the problem of poor consistency of LED light source brightness and color coordinates in traditional backlight modules, but also has the function of diffusing light, which is beneficial to further increase the uniformity of the display panel.

Embodiment 3

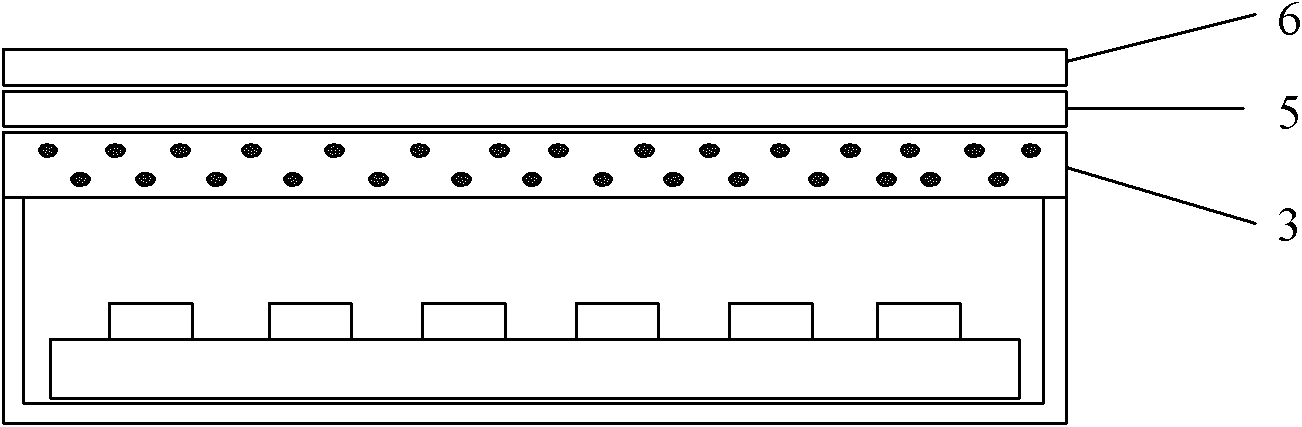

[0027] figure 2 A schematic structural diagram of the direct-lit LED backlight module provided by the third embodiment of the present invention is shown, and for convenience of description, only parts related to this embodiment are shown.

[0028] In this embodiment, a diffusion sheet 5 may be added on the light emitting surface of the light guide plate 3 to increase the uniformity of the backlight.

[0029] In this embodiment, a light-enhancing sheet 6 may be further provided on the light-emitting surface of the diffusion sheet 5 to provide a high-brightness uniform backlight for the display panel, such as figure 2 .

[0030] In this embodiment, when the light guide plate 3 has a very superior light diffusion performance, it is also possible to add the light enhancing sheet 6 only on the light emitting surface of the light guide plate.

[0031] The present invention directly arranges bare LED chips on the printed circuit board, and then arranges a light guide plate that u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com