Method for separating gas

A gas and goaf technology, which is applied in earth-moving drilling, production of fluids, wellbore/well components, etc., can solve the problems of low efficiency, increased number of separation devices, and high separation cost, and achieves low separation cost, energy saving, The effect of high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

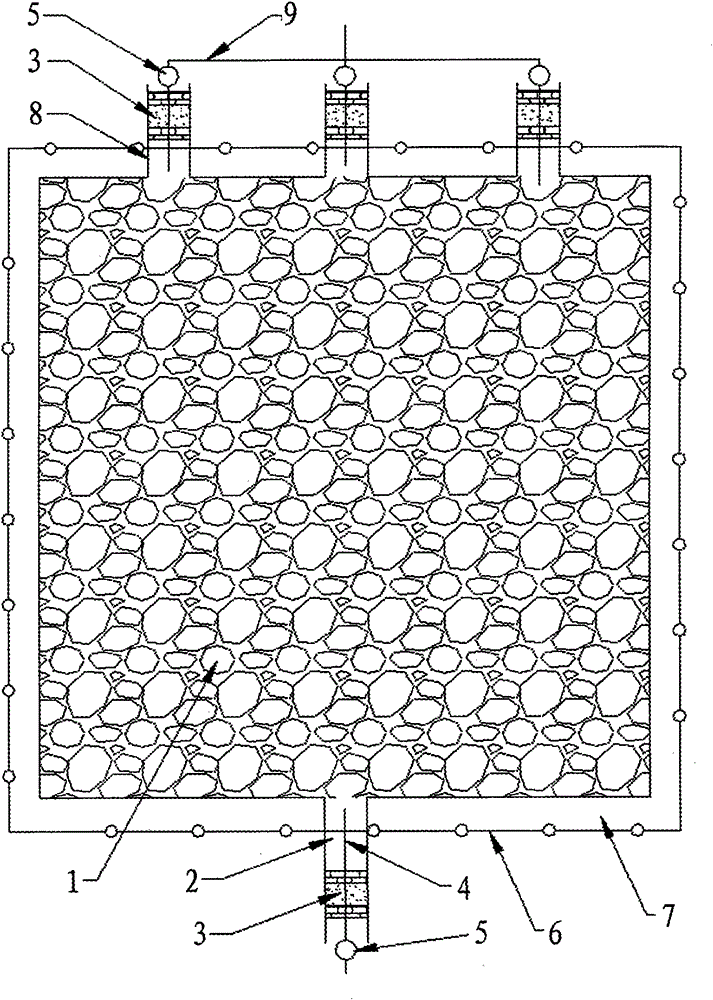

[0030] Combine below figure 1 The method of the present invention will be further described in detail, but the present invention is not limited to the following.

[0031] According to the different goaf conditions of each mine, the goaf 1 with very isolated conditions is selected, mainly for complete isolation from other areas of the mine. In addition, the goaf should be far enough from the surface, and the surface soil layer should be thick, so that It can ensure the complete isolation of the goaf, prevent the occurrence of gas explosions in the goaf, spontaneous combustion of floating coal and other phenomena, and the impact on other areas of the mine when disasters occur, and also ensure that disasters are easy to close and deal with.

[0032] All the outlets 2 and 8 connected to the goaf 1 are all built with waterproof, fireproof and explosion-proof airtight walls 3 . There must be enough isolated coal pillars 7 and isolated coal pillar boundaries 6 between the surroundin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com