Square or flat material production line jet cooling system

A cooling system and production line technology, applied in furnaces, heat treatment equipment, quenching devices, etc., can solve problems such as oil quenching environment problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

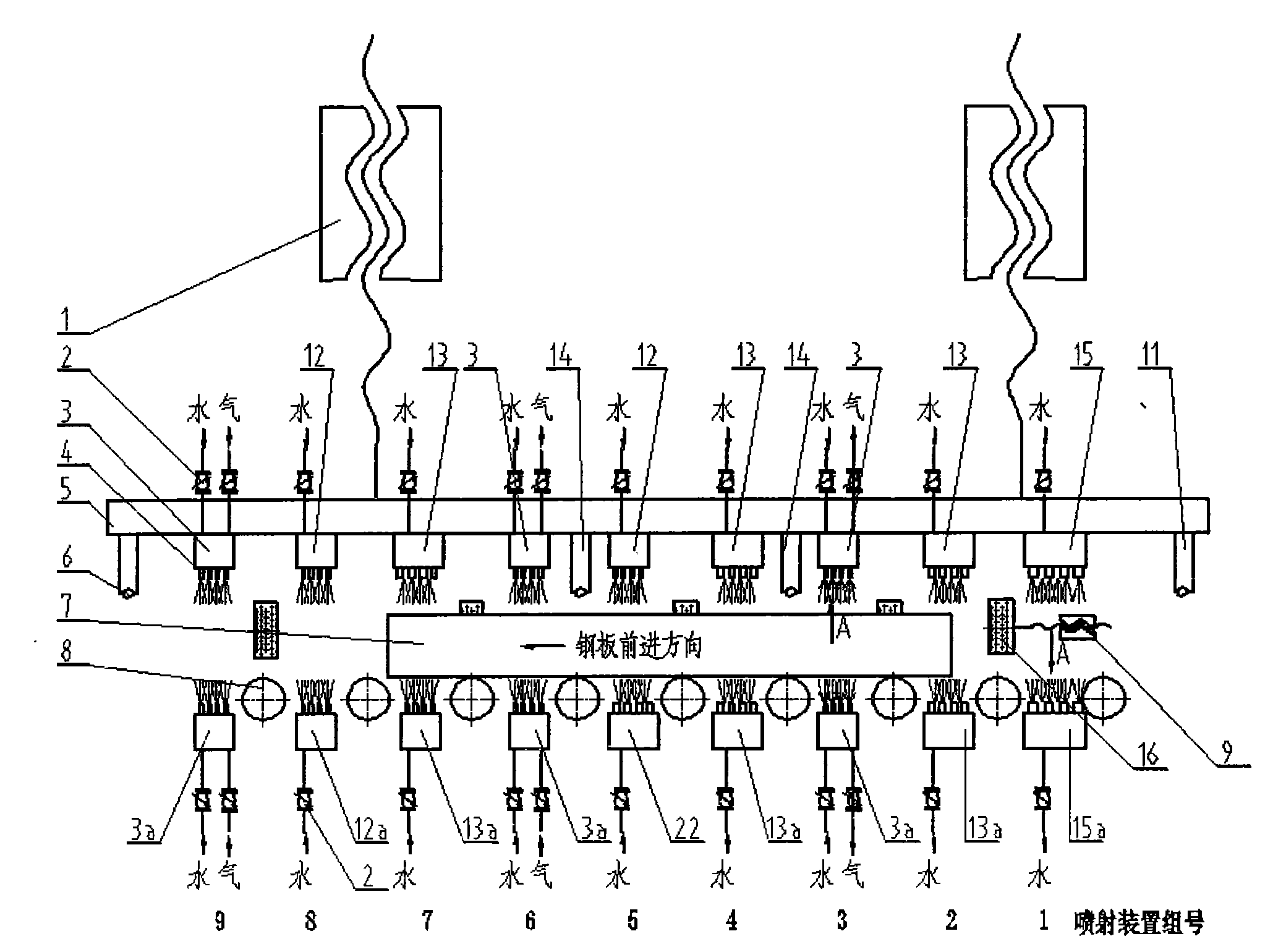

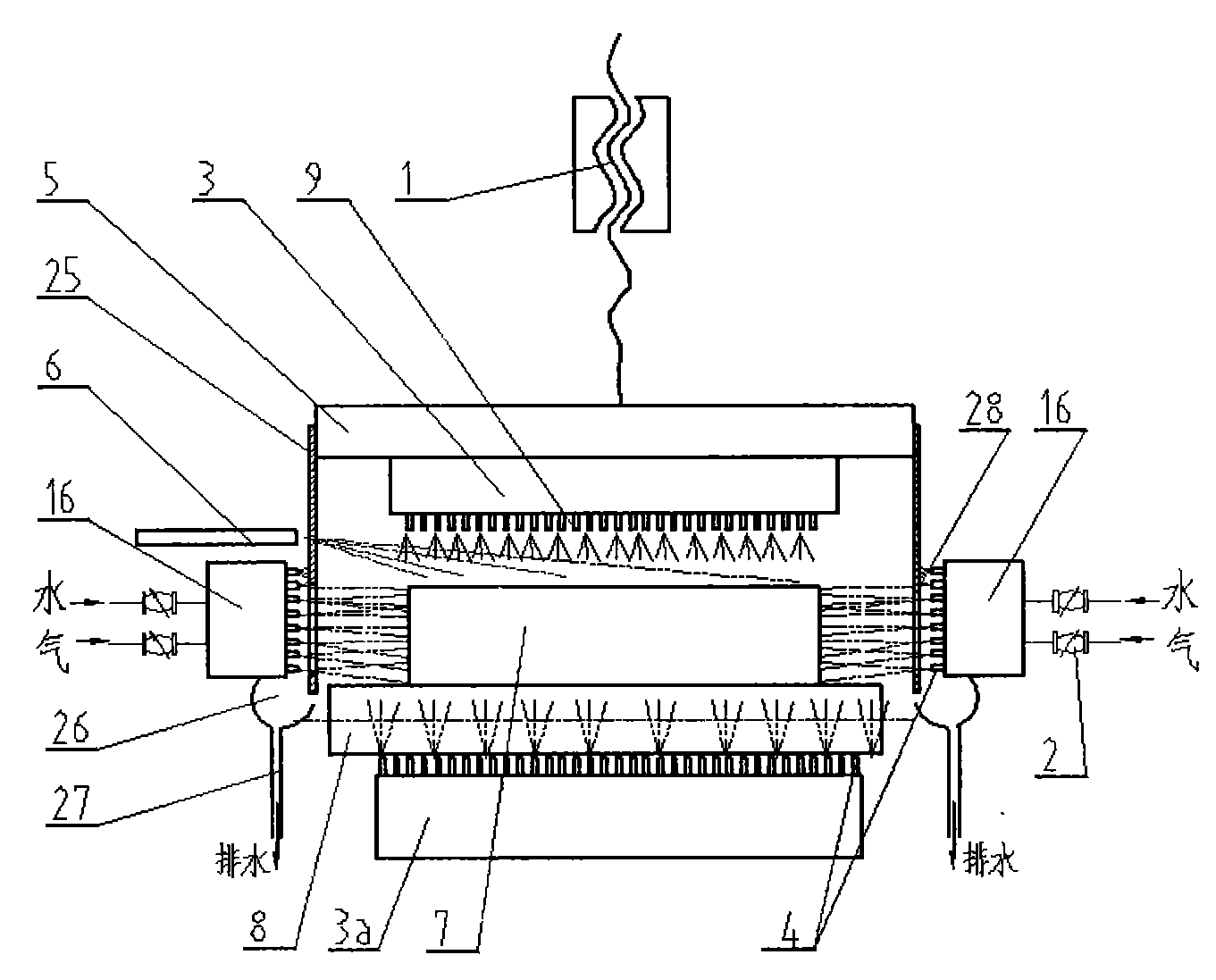

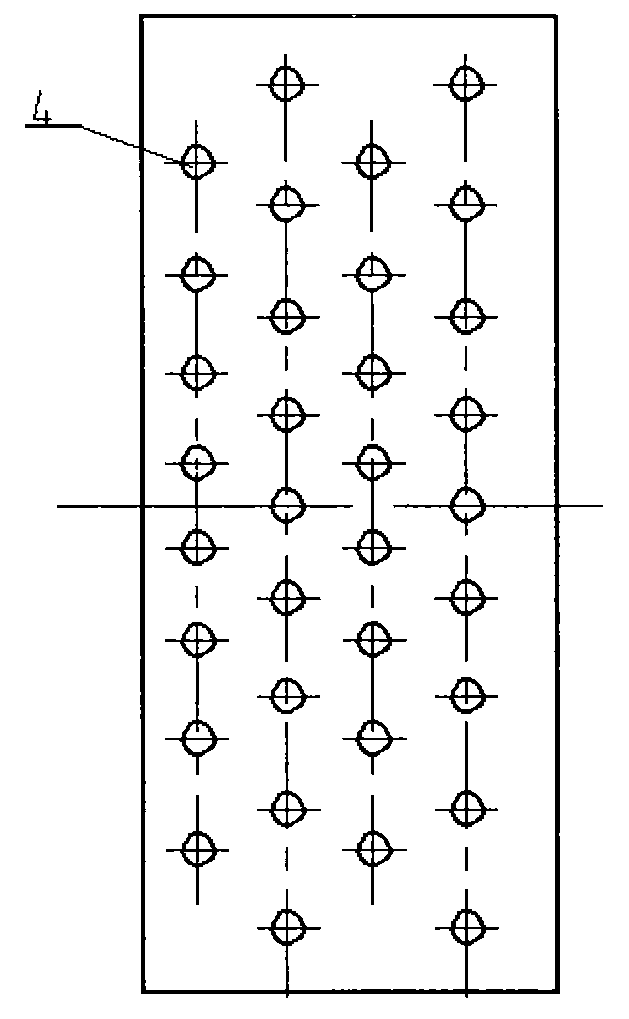

[0012] see figure 1 , The spray cooling system of the square flat material production line is mainly composed of: 1 set of upper and lower strong cooling spray devices, namely 15 and 15a; 3 sets of upper and lower intermediate cooling spray devices, namely 13 and 13a; 2 sets of upper and lower weak cooling spray devices, namely 12 and 12a ; 3 groups of upper and lower aerosol spraying devices, namely 3 and 3a; 5 groups of side cooling spraying devices 16, and 3 purging devices 11, 14, 6 are respectively located at the entrance, middle and exit of the production line. The upper and lower cooling injection devices are installed between two adjacent roller tables 8, the upper strong cooling is to the lower strong cooling, the upper middle cooling is to the lower middle cooling, the upper weak cooling is to the lower weak cooling, and the upper air mist is to the lower air mist, one by one correspond. The order of arrangement of strong, medium and weak aerosol spraying is (viewed...

Embodiment 2

[0019]The preparation for heat treatment is a solid stainless steel plate 1Cr18Ni9Ti with a thickness of 10mm. The equipment is the same as in Example 1. Lift the upper jet cooling device so that the nozzle is 280mm above the upper surface of the roller table 7. Turn on the 2nd group of medium cooling spray, the 3rd group of aerosol, the 5th group of weak cooling, the 8th group of weak cooling and the 9th group of aerosol. The valve opening degree of the second group of strong cold flow control device is 80%; the third group of aerosol spray device, the water valve opening degree of the flow control device is 60%, and the air is 70%; the fifth group of weak cold flow control device The water valve opening degree is 80% %; the opening degree of the water valve of the weak cold flow control device of the 8th group is 40%; the opening degree of the water valve of the flow control device of the 9th group is 30% and the gas is 80%. Due to the thinness of the square flat material,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com