Toughening process for high-tensile-strength recycled polyester sheet

A technology of high tensile strength and recycled polyester, which is applied in the field of toughening technology of polyester sheets, can solve the problems of sheet tensile and impact performance reduction, limit the use range of sheets, etc., and achieve enhanced impact and tensile performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

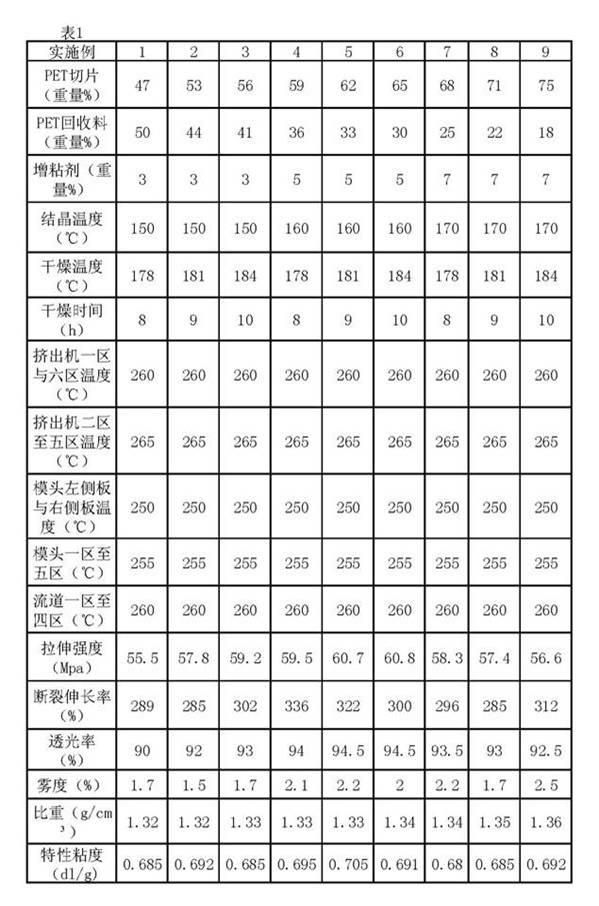

Examples

Embodiment 1

[0030] A high tensile strength recycled polyester sheet toughening process, the steps are as follows:

[0031] The weight percent is 47% PET chip, 50% PET reclaimed material, 3% thickening agent to prepare material, and described thickening agent is made up of the following each composition and the percentage that each composition accounts for thickening agent is: p-benzene 50% ethylene glycol diformate, 2% ethylene glycol isophthalate, 30% polyol acid, 17.5% polyol ester, 0.5% stearate;

[0032] Fully mix the prepared raw materials in a low-speed mixer, and input them into the crystallization tower for crystallization and drying. The crystallization temperature is 150°C, the drying temperature is 178°C, and the drying time is 8 hours. The dried materials are transported to the extruder For extrusion and plasticization, the extruder is divided into six zones, and the temperature of each zone is: Zone 1: 260°C, Zone 2: 265°C, Zone 3: 265°C, Zone 4: 265°C, Zone 5: 265 ℃, six zo...

Embodiment 2

[0035] The weight percentage is 53% PET chips, 44% PET reclaimed material, 3% tackifier, and the tackifier is composed of the following components and the percentage of each component in the tackifier is: p-benzene 53% ethylene glycol diformate, 2% ethylene glycol isophthalate, 14.5% polyol acid, 30% polyol ester, 0.5% stearate;

[0036] Fully mix the prepared raw materials evenly in a low-speed mixer, and input them into a crystallization tower for crystallization and drying. The crystallization temperature is 150°C, the drying temperature is 181°C, and the drying time is 9 hours.

Embodiment 3

[0038] The weight percentage is 56% PET chips, 41% PET reclaimed material, 3% tackifier, and the tackifier is composed of the following components and the percentage of each component in the tackifier is: p-benzene 55% ethylene glycol diformate, 2% ethylene glycol isophthalate, 20.5% polyol acid, 22% polyol ester, 0.5% stearate;

[0039] Fully mix the prepared raw materials evenly in a low-speed mixer, and input them into a crystallization tower for crystallization and drying. The crystallization temperature is 150°C, the drying temperature is 184°C, and the drying time is 10 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com