Method for welding double-metal drill reamer

A welding method, drilling reamer technology, applied in the direction of welding equipment, metal processing equipment, high-frequency current welding equipment, etc., can solve the problems of internal stress, deformation tool precision, welding is not firm, etc., to achieve the elimination of internal stress not suitable for deformation , good precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

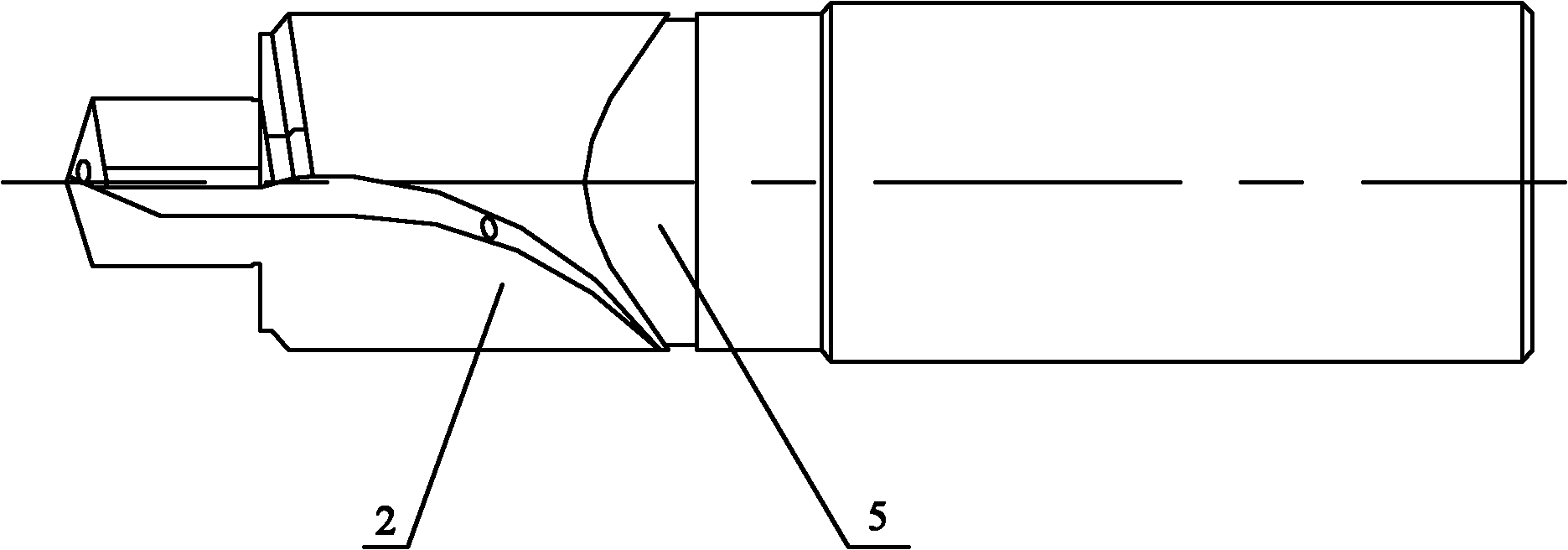

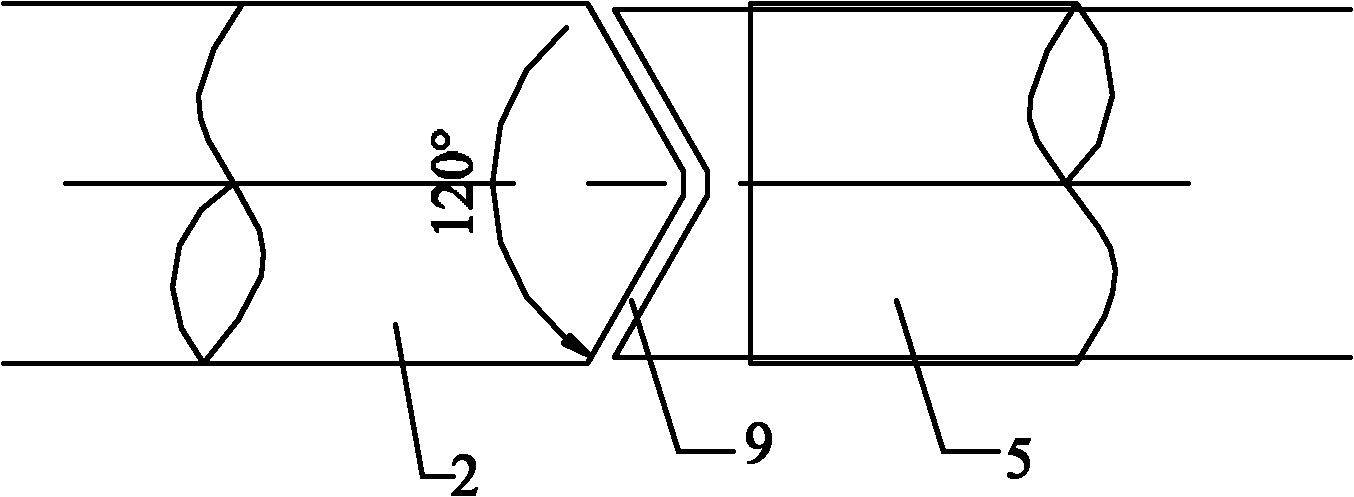

[0015] Figure 1a It is a structural diagram of a drill reamer. The left cutter head 2 is a hard alloy with a grade of K10, and the right handle 5 is a steel with a grade of 40Cr. refer to Figure 1b , V-shaped welding is adopted, and the V-shaped welding surface 9 is shown in the figure, which can increase the welding area and combine more firmly.

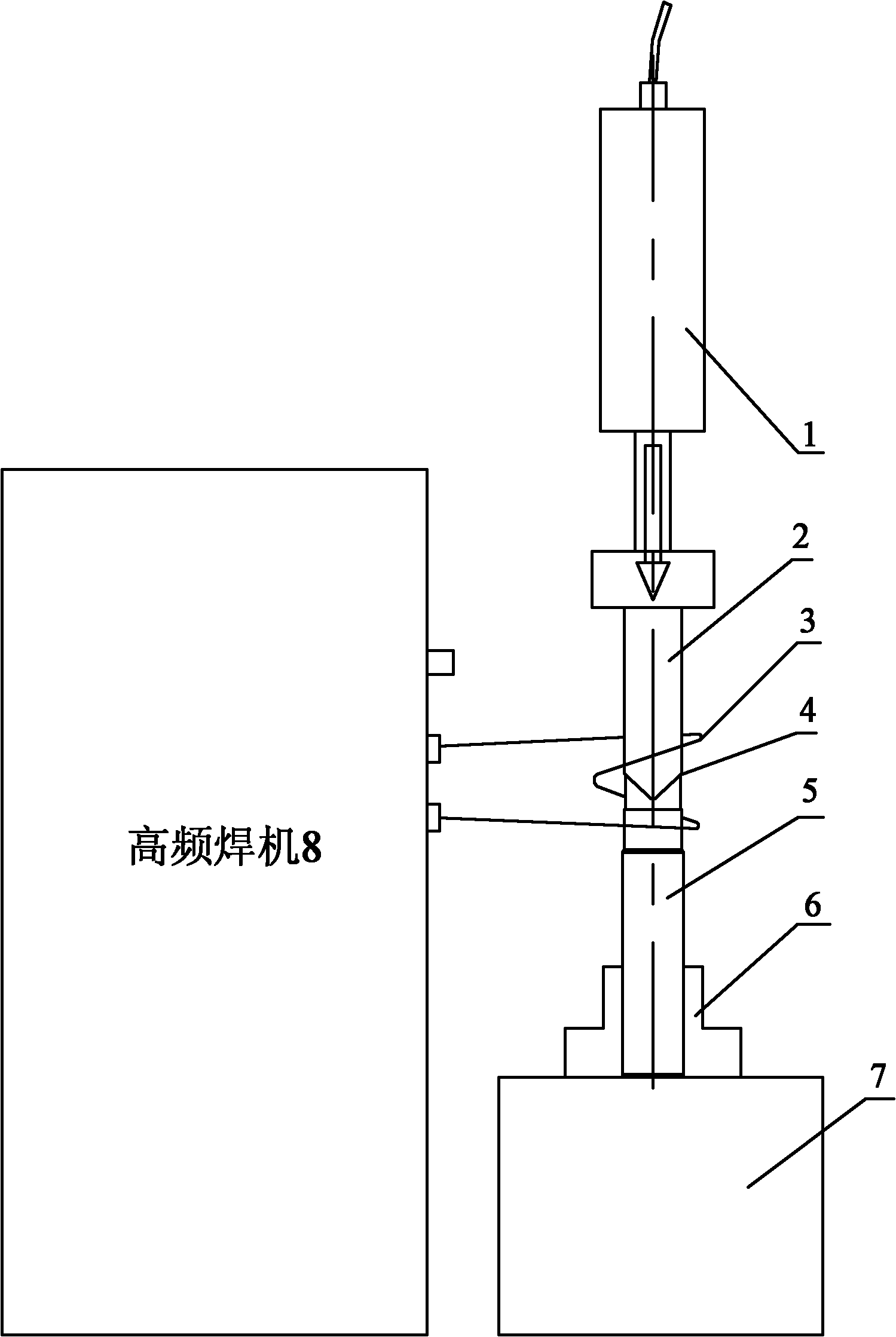

[0016] figure 2 is a welding schematic. The device includes a cylinder 1, a cutter head 2, an induction coil 3, a sandwich welding piece 4, a knife handle 5, a fixed seat 6, a base 7 and a high-frequency welding machine 8. The connection relationship is shown in the figure. Stand up the knife handle 5 during welding, first smear the solder paste on the welding surface, put the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com