Automatic streamline production process for butterfly spring

A production process and assembly line technology, applied in railway car body parts, transportation and packaging, vehicle parts, etc., can solve the problems of transfer workpiece to pressing position error, uneven transfer time, poor operating environment for workers, etc., and achieve low labor intensity. , The effect of high yield and improved operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

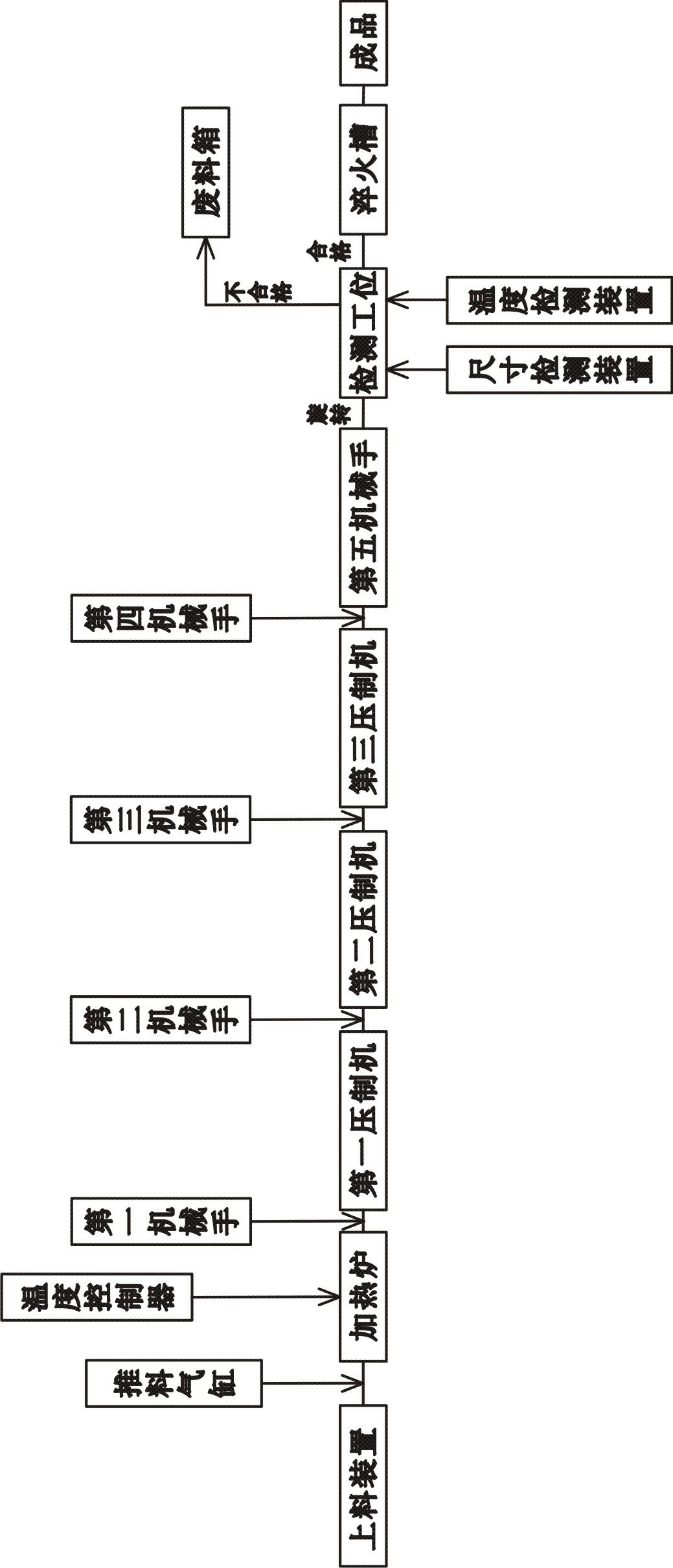

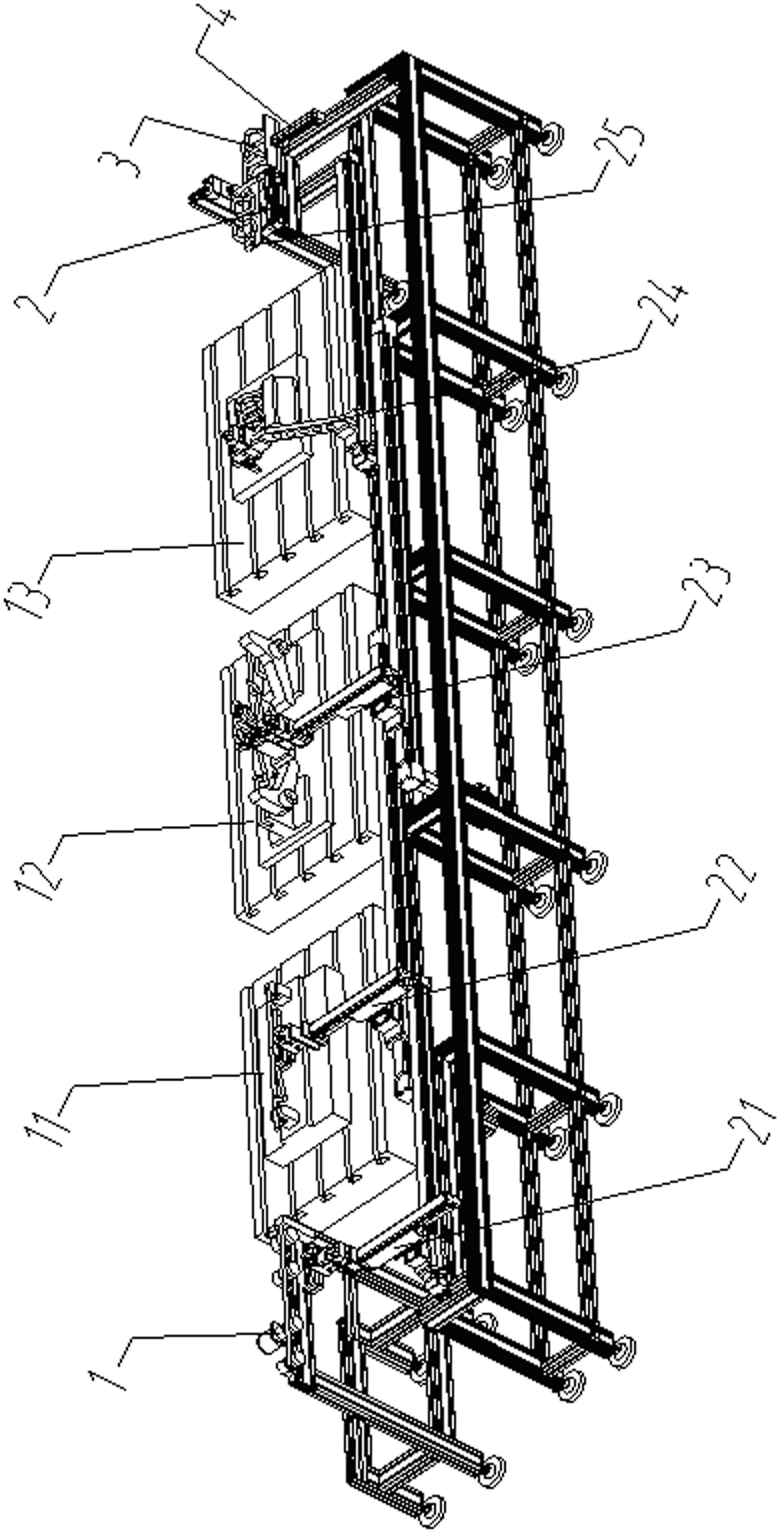

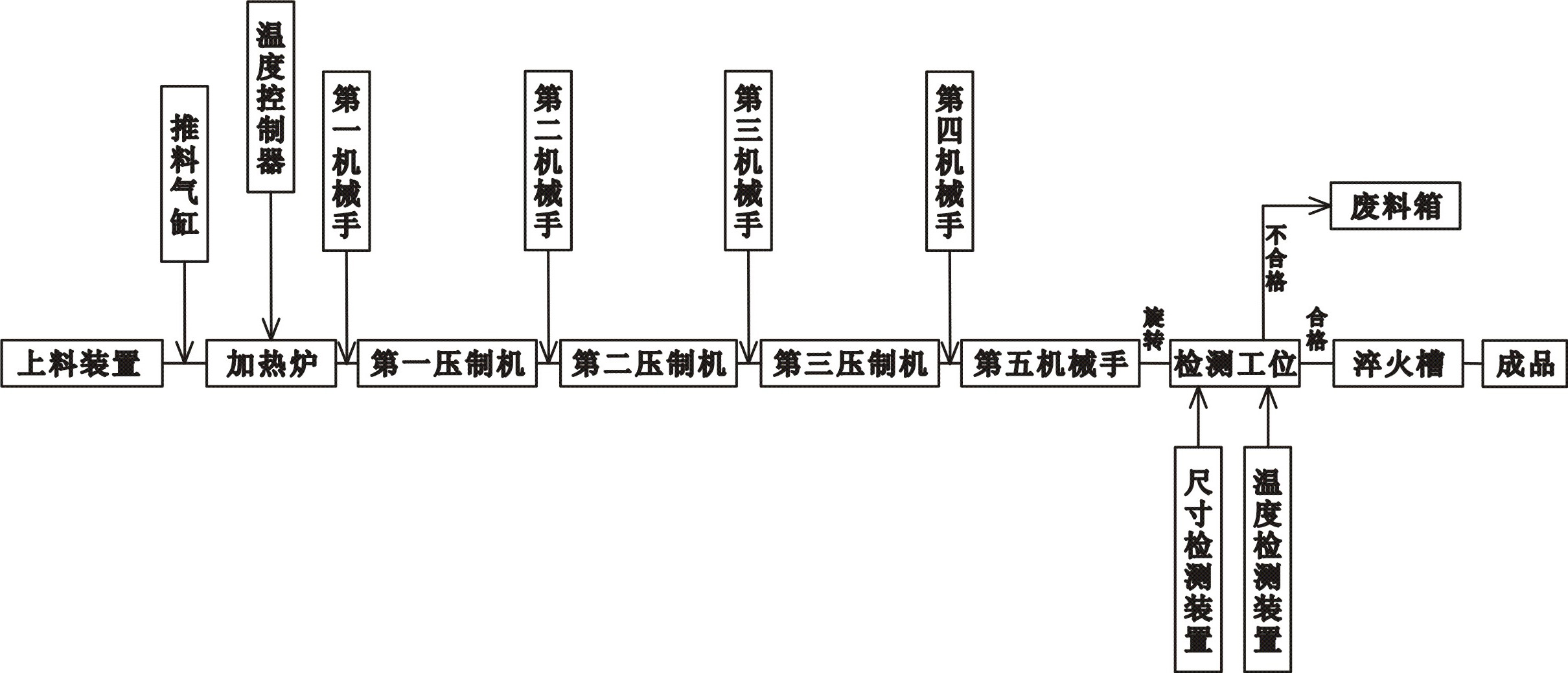

[0021] See figure 1 with figure 2 , The equipment used in the butterfly spring automated assembly line production process sequentially includes a feeding device, a heating furnace, a first manipulator 21, a first press 11, a second manipulator 22, a second press 12, a third manipulator 23, and a third press Machine 13, fourth manipulator 24, fifth manipulator 25, detection station 3, size detection device, temperature detection device, quenching tank and waste box, the assembly line production process steps are as follows:

[0022] a. Choose a slender shaft as the blank;

[0023] b. The blank is pushed from the feeding device through the pusher cylinder to the heating furnace to be heated to 1000-1200°C, and a temperature controller is installed in the heating furnace, so that the heating furnace has a temperature control function to ensure that the blank is in the heating furnace It is heated to 1000~1200℃ in 3.5 seconds, eliminating the need for workpiece heating detection stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com