Environment-friendly heat treatment process for large shaft forgings

A technology for shaft parts and heat treatment furnaces, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve the problems of large shaft parts with large weight, large cross-sectional size changes, and low oil cooling hardness, etc., to reduce quenching deformation and cracking tendency, overcome the effect of fast cooling rate and improve working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

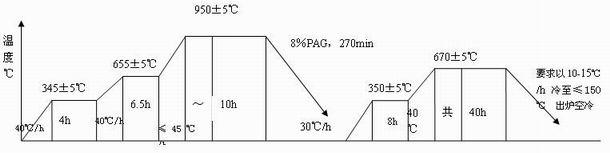

[0025] combine figure 1 , the quenching process of a large rotor made of 30CrMoV steel and weighing 28 tons, the specific process steps are as follows:

[0026] (1) Lift the large rotor vertically into the heat treatment furnace by using chucks, raise the temperature to 345±5°C at a rate of 40°C / hour, and keep it warm for 4 hours; then raise the temperature to 655±5°C at a rate of 40°C / hour , keep warm for 6.5 hours;

[0027] (2) After heat preservation at 655°C, heat up to the quenching temperature of 950±5°C at a rate of 45°C / hour, and hold for 10 hours;

[0028] (3), quickly hang the large rotor vertically into the quenching tank, in terms of volume percentage, the quenching medium in the quenching tank is 8% PAG and 92% water, the temperature of the quenching medium is controlled below 50°C, and quenched for 270 minutes;

[0029] (4) Lift out the large rotor and cool it below 200°C, install the furnace, heat up to 350±5°C at a speed of 30°C / hour, and keep it warm for 8 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com