Chemical method for preparing copper oxide crystals with biological micro-nano structures by thermal decomposition

A technology of micro-nano structure and copper oxide, which is applied in the field of material chemistry, can solve the problems of large amount of reagents, complicated process, and high energy consumption, and achieve the effect of low cost, simple reaction principle, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Preparation: For the pretreatment of cotton cloth, wash 50g of commercially available cotton cloth three times with tap water, flatten it and immerse it in a 1000ml beaker containing 800ml of 0.005mol / L sodium hydroxide aqueous solution, and heat it to Boil and keep boiling for 1h. Cool to room temperature, wash twice with 500-700ml distilled water, then pour 500-700ml distilled water, and ultrasonically clean 3 times with distilled water, 15min each time. Then, put the above-mentioned treated cotton cloth into 800ml mixed acid with the molar ratio of sulfuric acid and oxalic acid = 2: 1, and sonicate for 1 h, wherein the concentration of sulfuric acid is 2 mol / L, and let it stand for 24 h. Take out the cotton cloth, wash it twice with 500-700ml of distilled water, and then ultrasonically clean it with distilled water for 3 times, each time for 15 minutes. Finally, take the cotton cloth out of the distilled water, squeeze the water as dry as possible with clean twee...

Embodiment 2

[0048] 1, preparatory work: with embodiment 1;

[0049] 2. Reaction steps: Weigh CuSO 4 ·5H 2 Add 25g of O crystals to a clean beaker, add distilled water to heat and dissolve, transfer to a 200ml volumetric flask after cooling to make 0.5mol / L CuSO 4 solution. Weigh 0.3g of the treated cotton cloth and place it in 50ml of 0.5mol / L CuSO 4 Put the solution in a 100ml beaker, ultrasonically soak for 30min, and after aging for 24h, take out the cotton cloth, dry it at 80°C, and finally put it into a muffle furnace, set the temperature at 600°C, and heat up at a rate of 5°C / min. After 6 hours, it was naturally cooled to room temperature, and the obtained product was characterized by SEM and XRD.

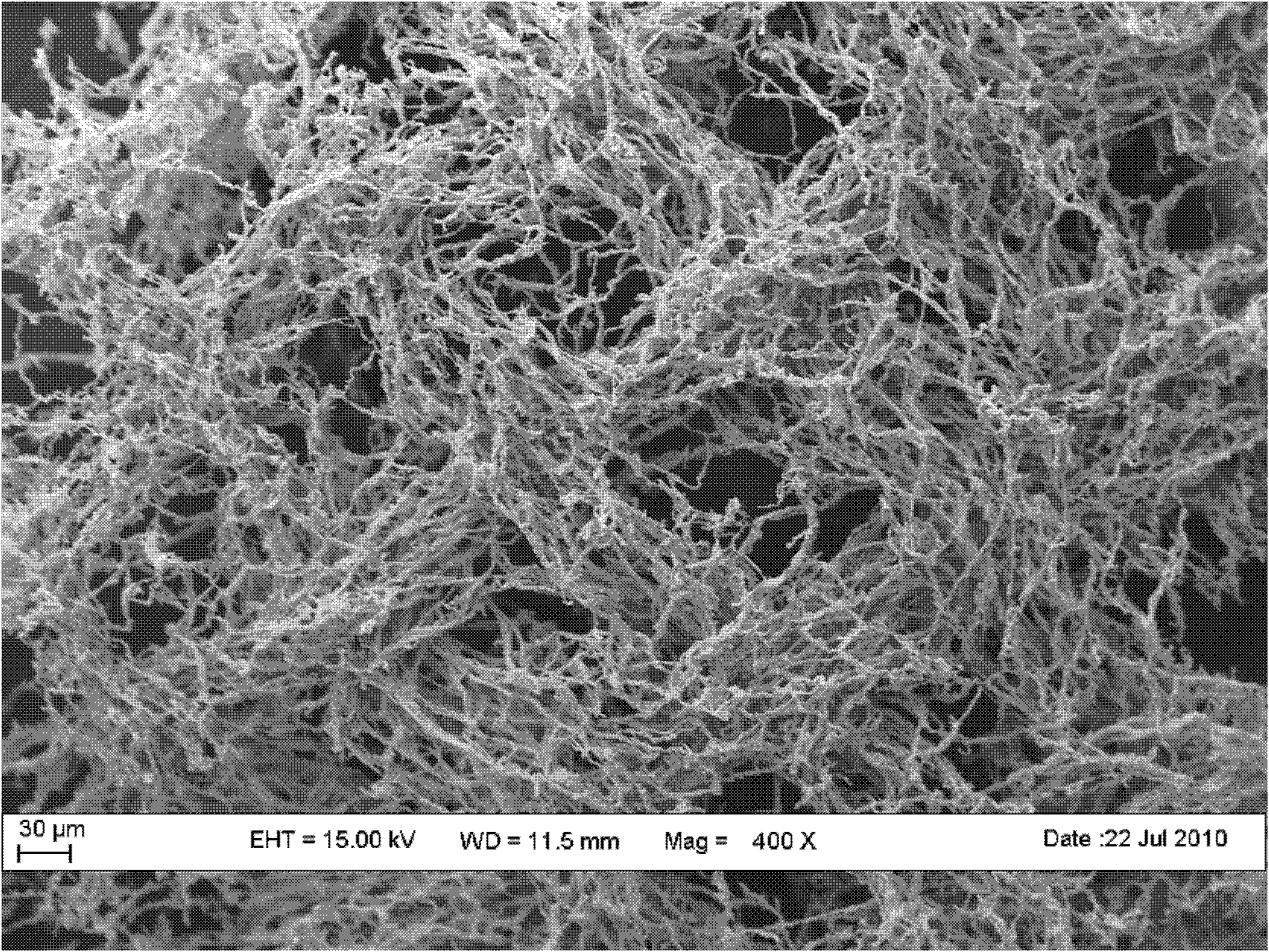

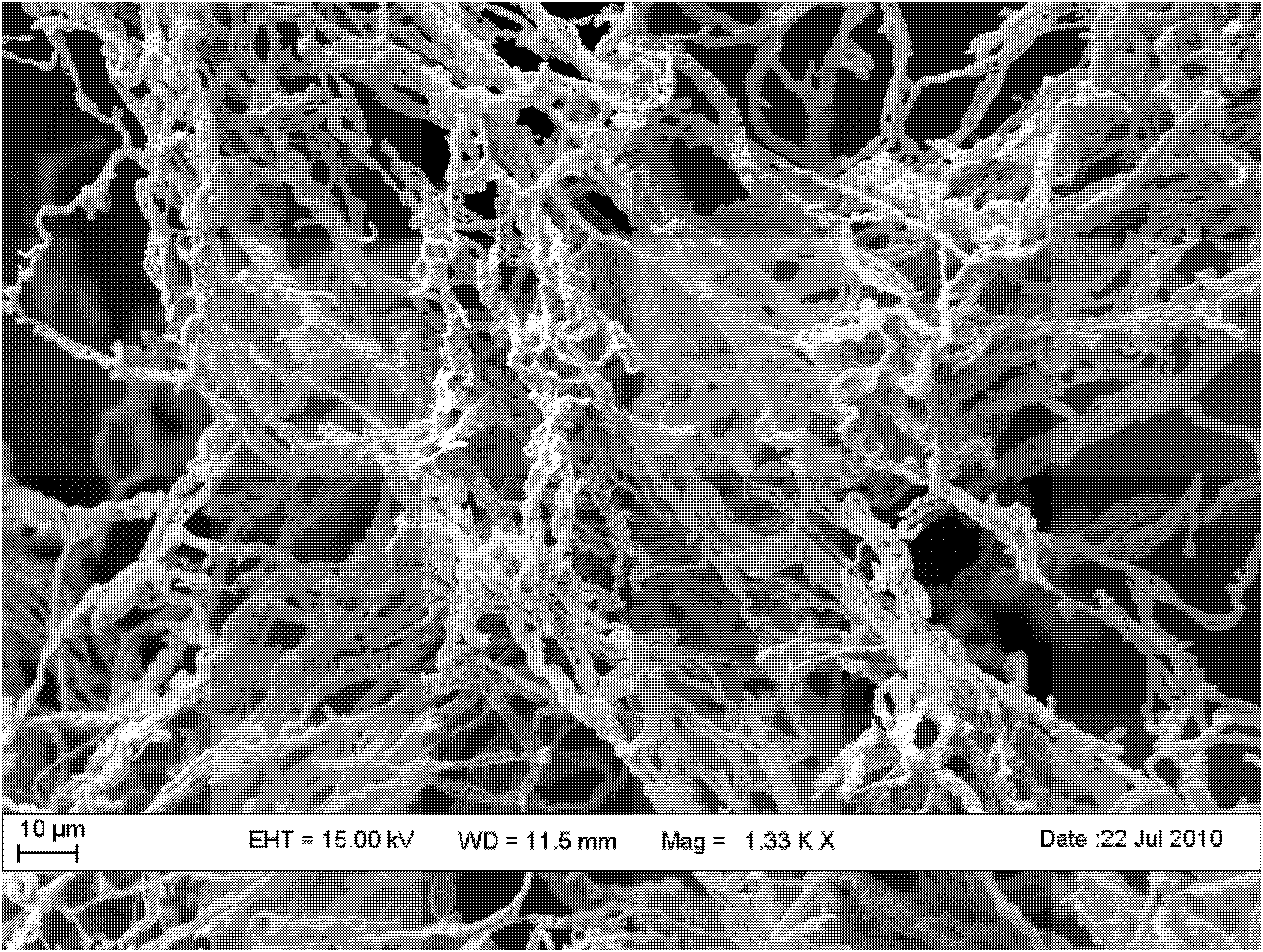

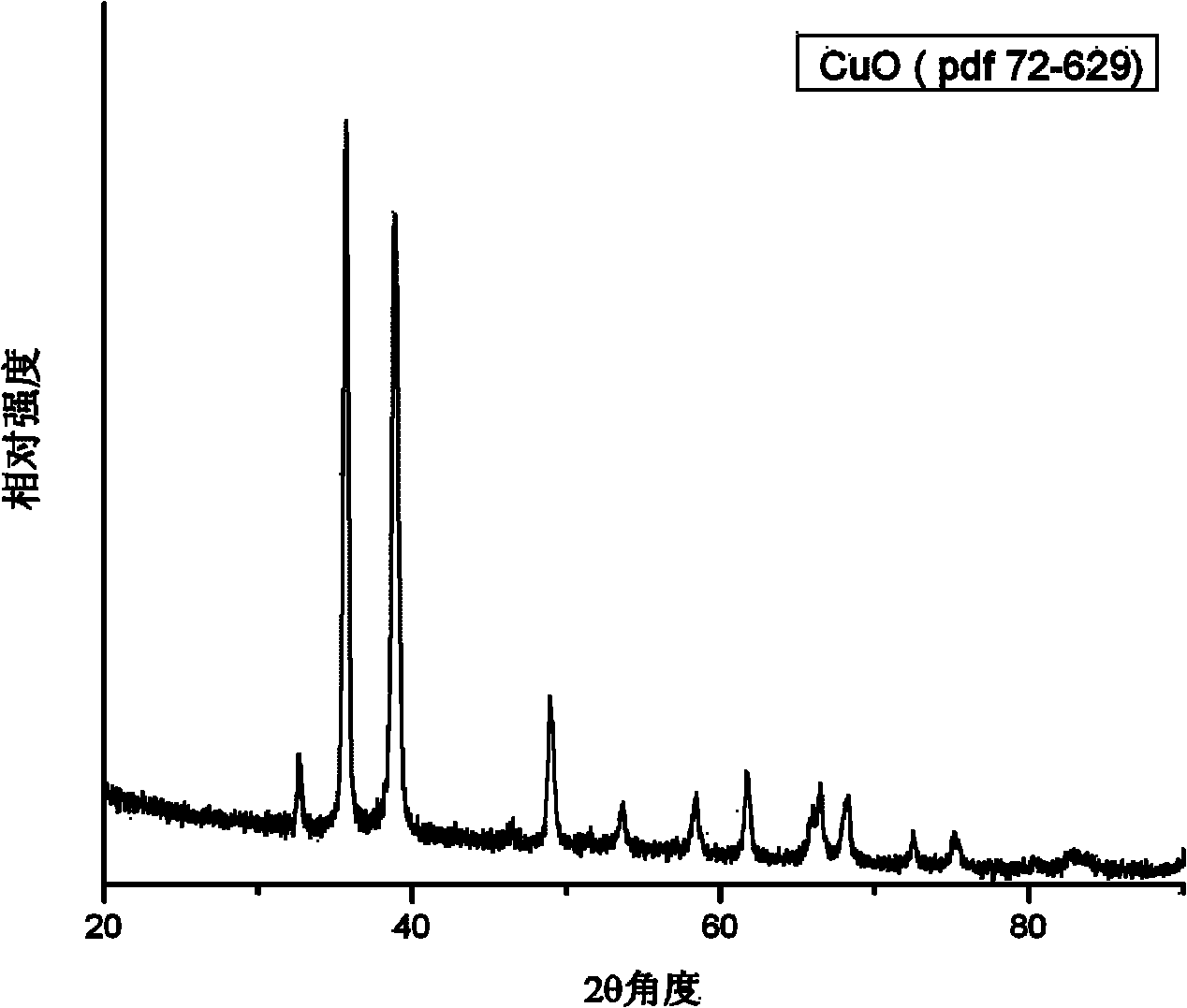

[0050] 3, aftertreatment: with embodiment 1, obtain nano-CuO sample color and be black, scanning electron microscope photo sees diagram 2-1 , see 2-2 for the XRD pattern.

Embodiment 3

[0052] 1, preparatory work: with embodiment 1;

[0053] 2. Reaction steps: Weigh CuSO 4 ·5H 2 Add 25g of O crystals to a clean beaker, add distilled water to heat and dissolve, transfer to a 200ml volumetric flask after cooling to make 0.5mol / L CuSO 4 solution. Weigh 0.3g of the treated cotton cloth and place it in 50ml of 0.5mol / L CuSO 4 Put the solution in a 100ml beaker, ultrasonically soak for 30min, and after aging for 24h, take out the cotton cloth, dry it at 80°C, and finally put it into a muffle furnace, set the temperature at 700°C, and heat up at a rate of 5°C / min. After 6 hours, it was naturally cooled to room temperature, and the obtained product was characterized by SEM and XRD.

[0054] 3, aftertreatment: with embodiment 1, obtain nano-CuO sample, product color is black, scanning electron microscope photo sees Figure 3-1 , see 3-2 for the XRD pattern.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com