One-way exhaust valve bag

An exhaust valve and one-way exhaust technology, which is applied in the field of packaging bags, can solve the problems of complex production process and high cost of double-layer bags, and achieve the effects of low cost and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

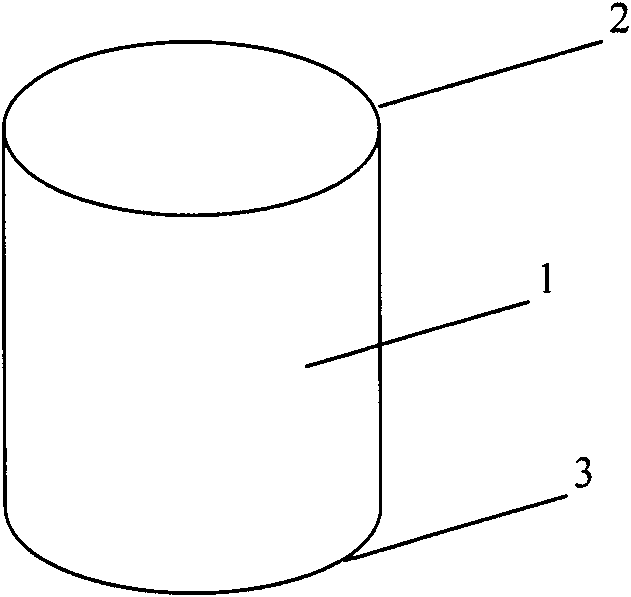

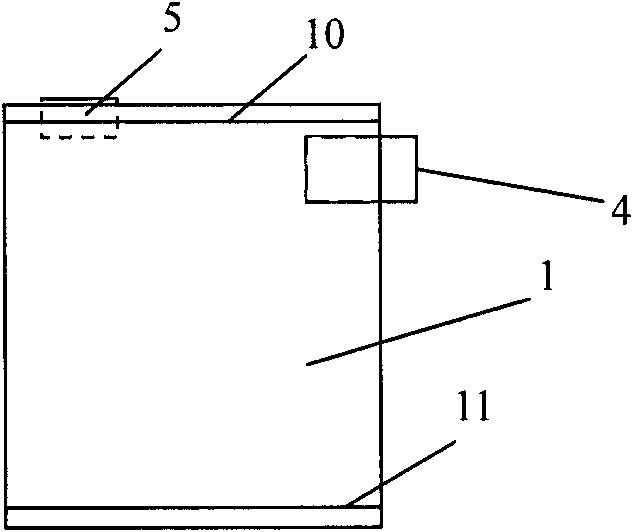

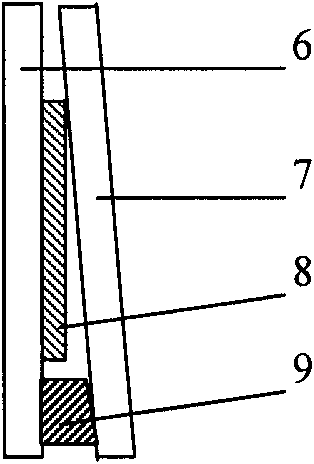

[0028] Will figure 1 Shown cylindrical polyethylene bag body 1, upper end 2, lower end 3, after flattening, valve port 4 is added in bag body. The valve port is a cylindrical self-sealing valve port that has been flattened, with a concave-convex buckle at one end. The feeding self-sealing valve port is located at one end of the bag body, and is glued or welded together with the bag body, and communicates with the storage cavity formed by the bag body and the outside. Its function is to fill the material. When the filling is completed, the material inlet will be closed automatically due to the pressure of the material in the bag. Figure 5 It is a change diagram before and after the filling of the self-sealing valve port 20 is completed. Wherein 19 is the discharge pipe of the filling equipment, which is inserted in the self-sealing valve port 20. After the filling is completed, the internal material 18 presses the self-sealing valve port to make it in a closed state. Of c...

Embodiment 2

[0031] Embodiment 2: as Figure 4The shown double-bottom one-way exhaust type square bottom valve bag includes a cylindrical polyethylene bag body 12, a rectangular bottom surface 13 and a bottom surface 14 formed by folding the bag body, and the bottom surface 14 is provided with a self-sealing valve port 15 for feeding. The folded parts and the adjacent feeding self-sealing ports 15 are bonded or welded to each other to ensure that the receiving chambers formed by 12, 13, 14 and 15 are airtight except for the valve ports. The feed self-sealing valve port is a cylindrical self-sealing valve port that has been flattened, and one end of the self-sealing valve port can be provided with a concave-convex buckle. The role of the feed self-sealing valve port is to fill the material. And when the filling is completed, the feeding port will be closed automatically due to the pressure of the material in the bag. Figure 5 It is a change diagram before and after the filling of the self...

Embodiment 3

[0033] Embodiment 3: It is basically the same as Embodiment 2, the difference is that micro-holes are punched on both bottom surfaces, a one-way exhaust device is provided, and an additional layer is provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com