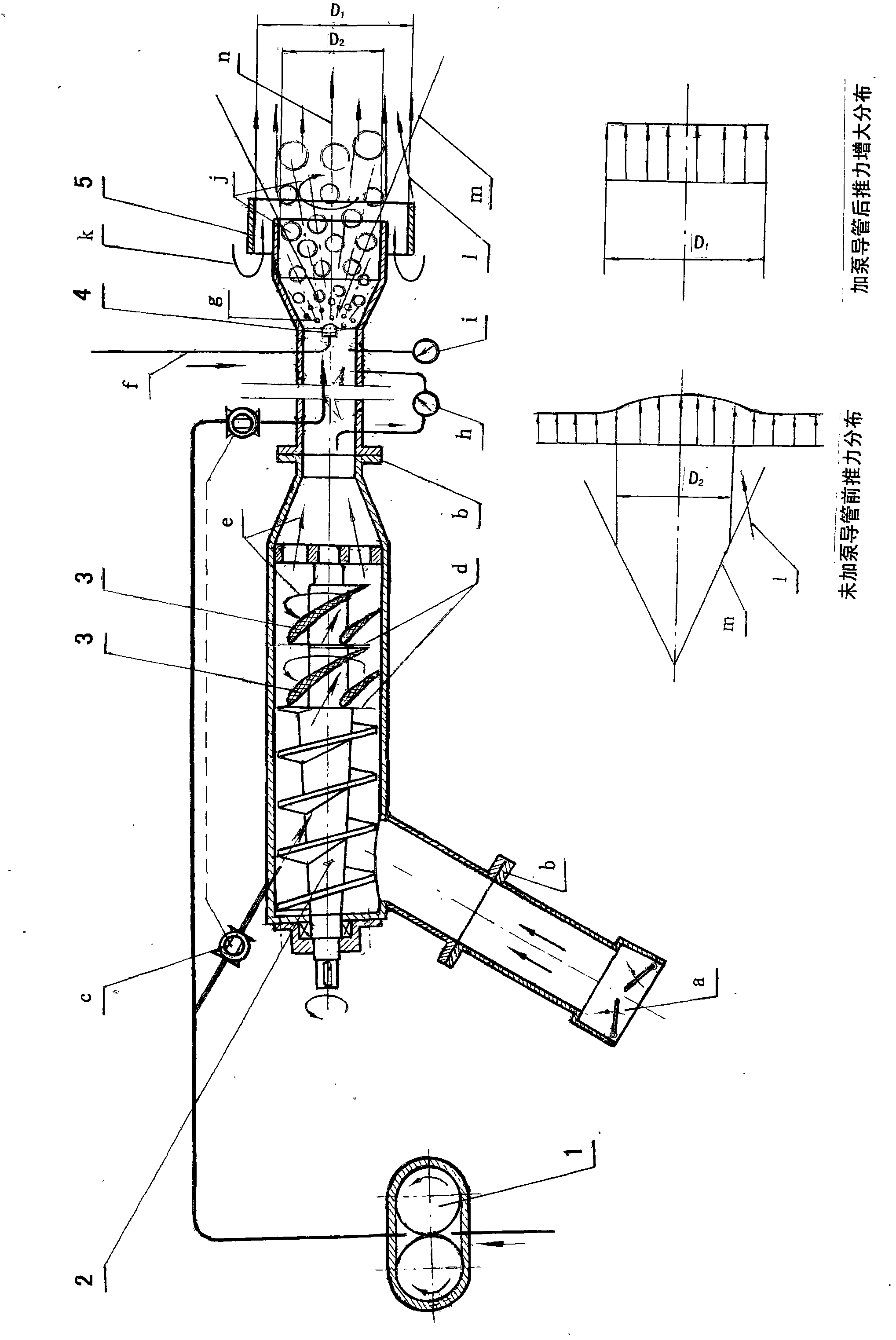

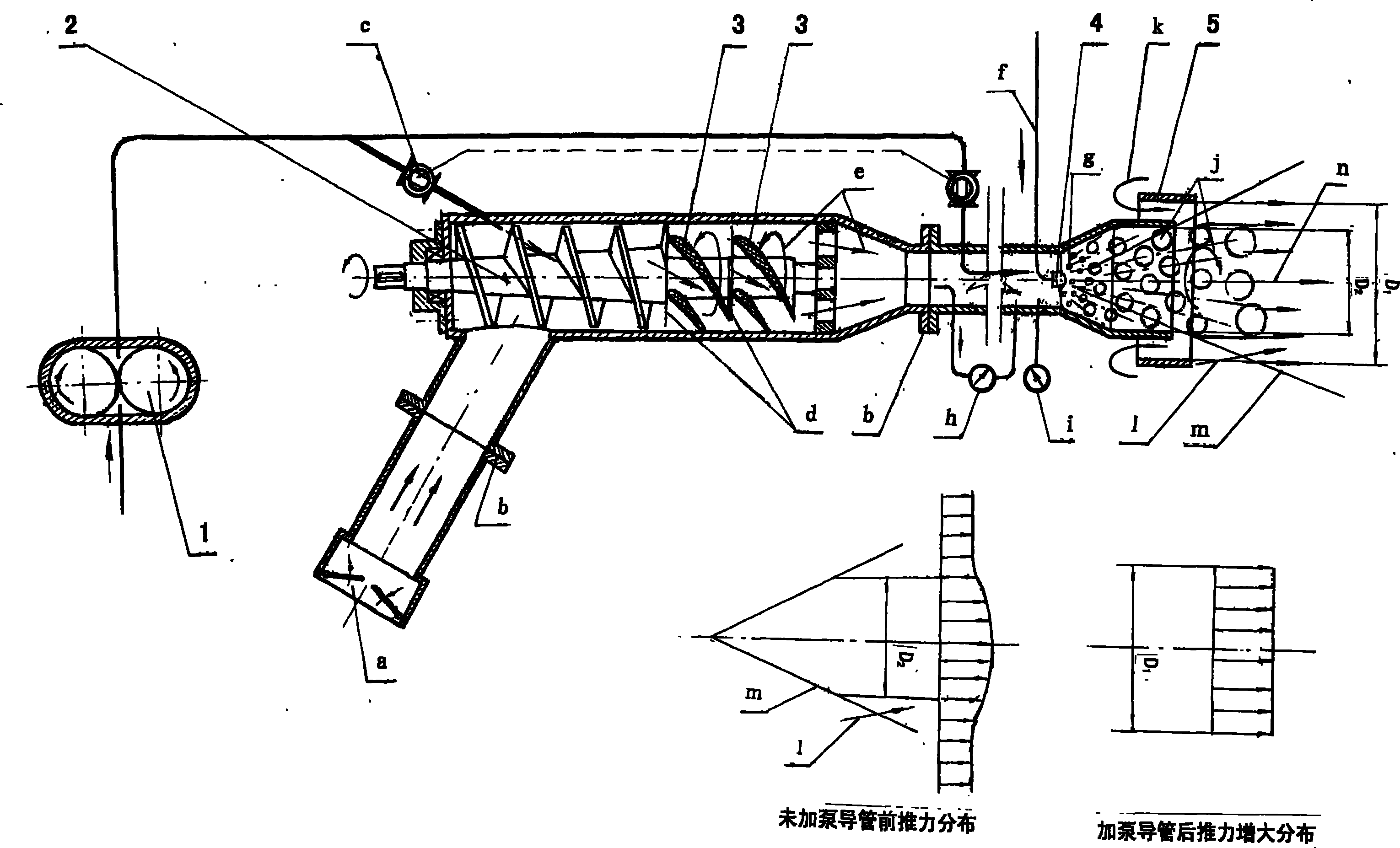

Pump-jet water propeller system for five-element combined ship

A water-jet propulsion and water-jet propulsion technology, which are applied in ship propulsion, propulsion parts, ship parts, etc., can solve the problems of complex structure, heavy weight, and no centrifugal force work, and achieve good structural manufacturability, light weight, high The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] 5.1 The first unit "Multi-stage Inner Series Dual Supercharging Double Arc Gear Pump" is the front pump, and today's small test pump is the booster of the two-stage sub-pump. The number of teeth and modulus of the first-stage slave pump and the second-stage slave pump are the same, so that they can be coaxially driven. Now the number of teeth is 12, the modulus is 8, the thickness of the first-stage tooth is 33mm, and the second-stage tooth is slightly thinner to achieve a strong boost. The rotation speed is 1450 rpm, and the theoretical flow rate is 226L / min, that is, it can generate more than 200 kg of high-pressure water per minute. Because the pump cavity of the rear pump is 1 meter long, the inner diameter is ¢200, and the volume is V=31.4L, it can be filled with water in a very short time and can be started. When the water intake of the upper and lower two front pumps is 0.45m 3 / min, the water pressure is very high, it plays the role of guaranteeing the rear pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com