Semiconductor encapsulating method

A packaging method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as wire collapse, difficulty in changing design, failure of packaged products, etc., and achieve low manufacturing costs and equipment maintenance costs. The effect of wire collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

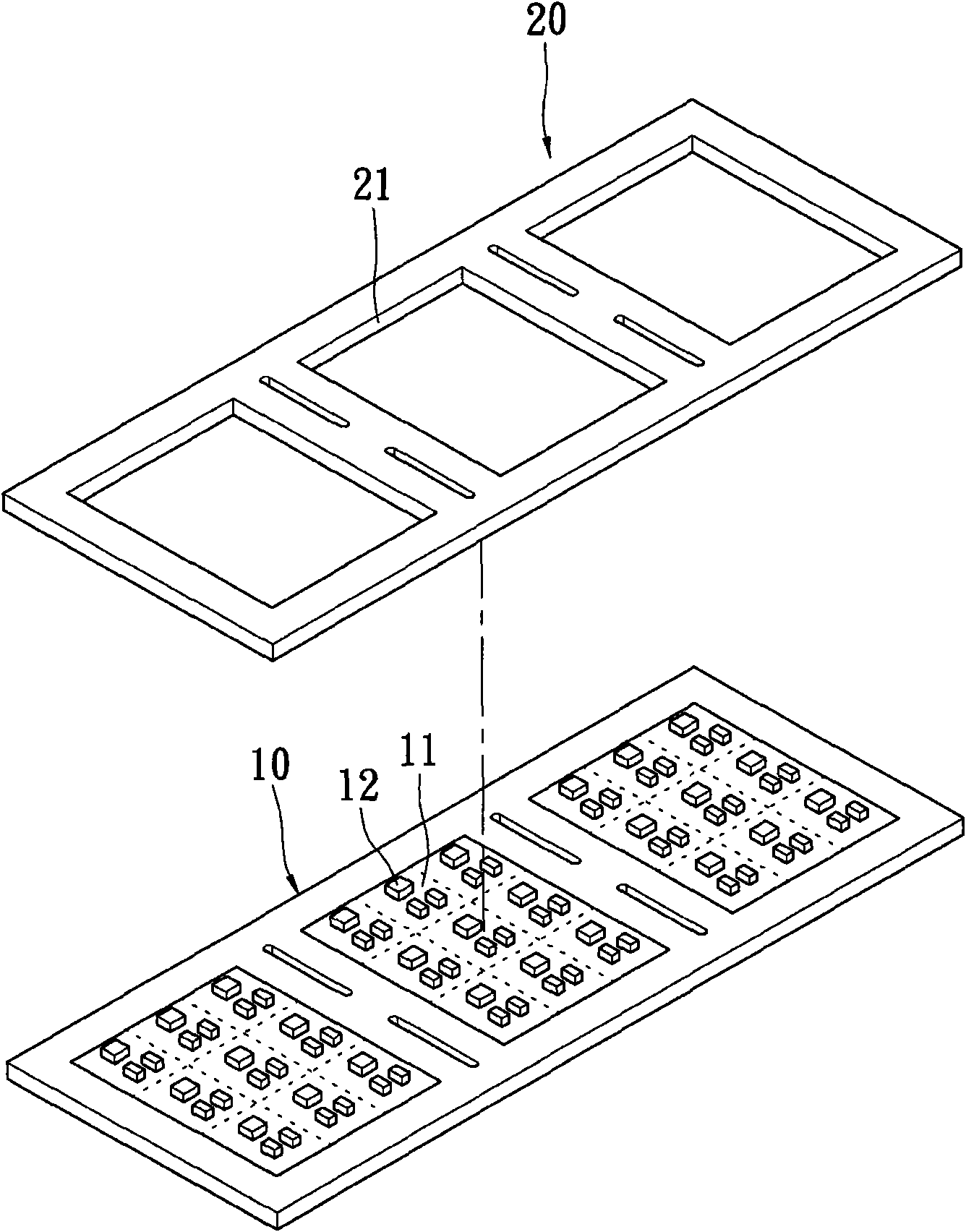

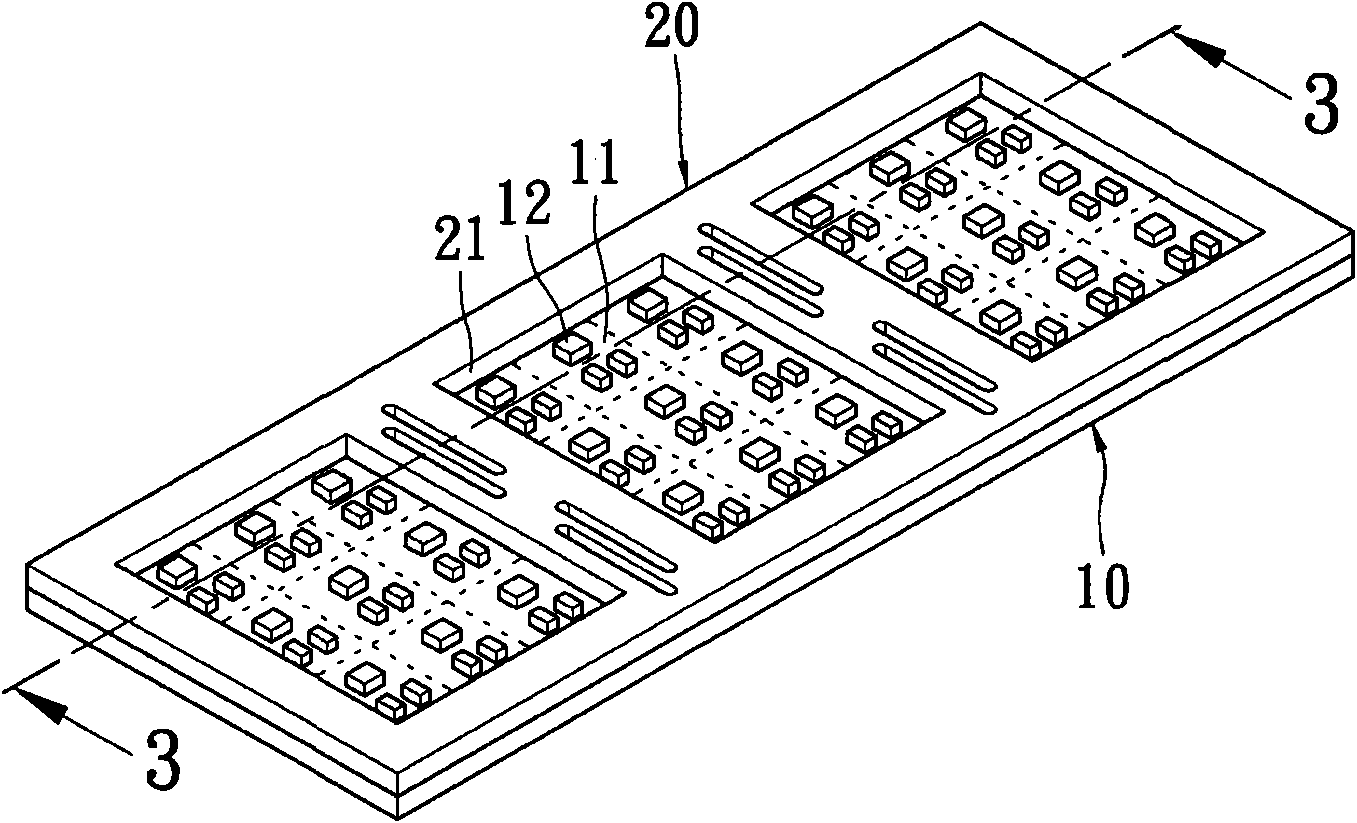

[0030] see figure 1 and figure 2 As shown, the present invention provides a semiconductor packaging method manufacturing method, which can be applied to various semiconductor packages, such as: System in Package Module (SIPModule). The manufacturing method includes the following steps:

[0031] (1) Prepare a substrate 10, which is divided into a plurality of packaging areas 11, and each packaging area 11 is provided with a plurality of electronic components 12 in an electrically connected manner. In the accompanying drawings, each packaging area 11 is provided with three electronic components. Take element 12 as an example. Wherein, the electronic component 12 can be determined according to the requirements of practical applications, and its type is not limited, and can be a chip, a passive component or a combination thereof. Wires (not shown in the figure) can be used to achieve electrical connection between the electronic component 12 and each package area 11 . In the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com