Bending welding forming method for rectangular steel pipe

A rectangular steel pipe, welding and forming technology, applied in the field of bending and welding forming, can solve the problems of complicated operation and limited bending angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the accompanying drawings.

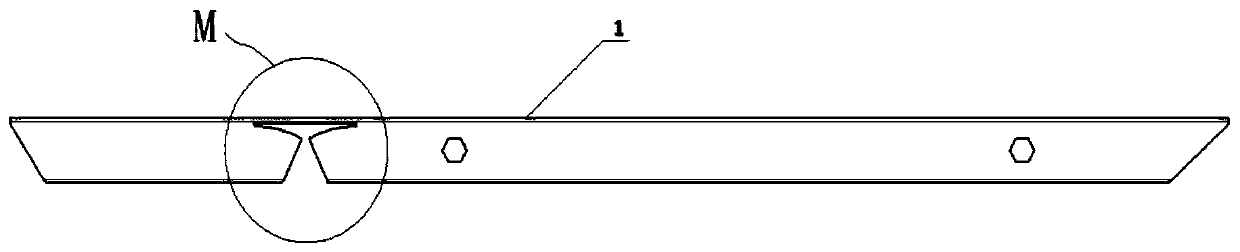

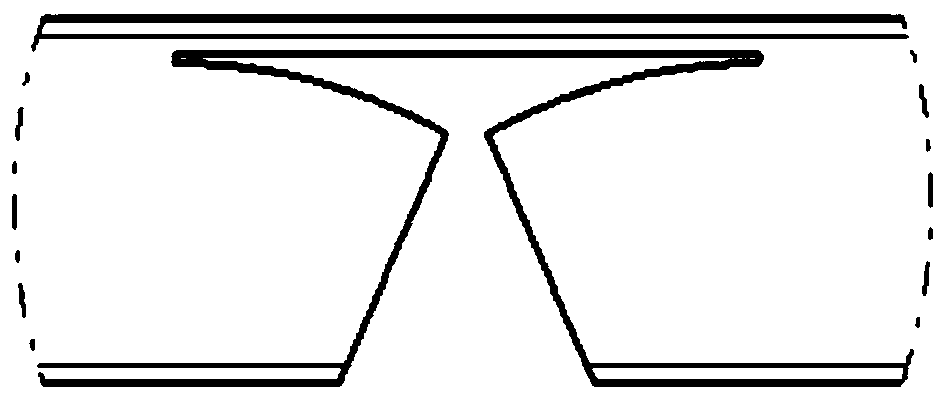

[0020] A bending welding forming method of a rectangular steel pipe, comprising the following steps: before the rectangular steel pipe is bent, a "T"-shaped cutting track is drawn according to the target bending angle, and a corresponding groove is cut on the side of the rectangular steel pipe by laser or plasma cutting method , and then bend the steel pipe corresponding to the groove, and weld the bent "T" groove.

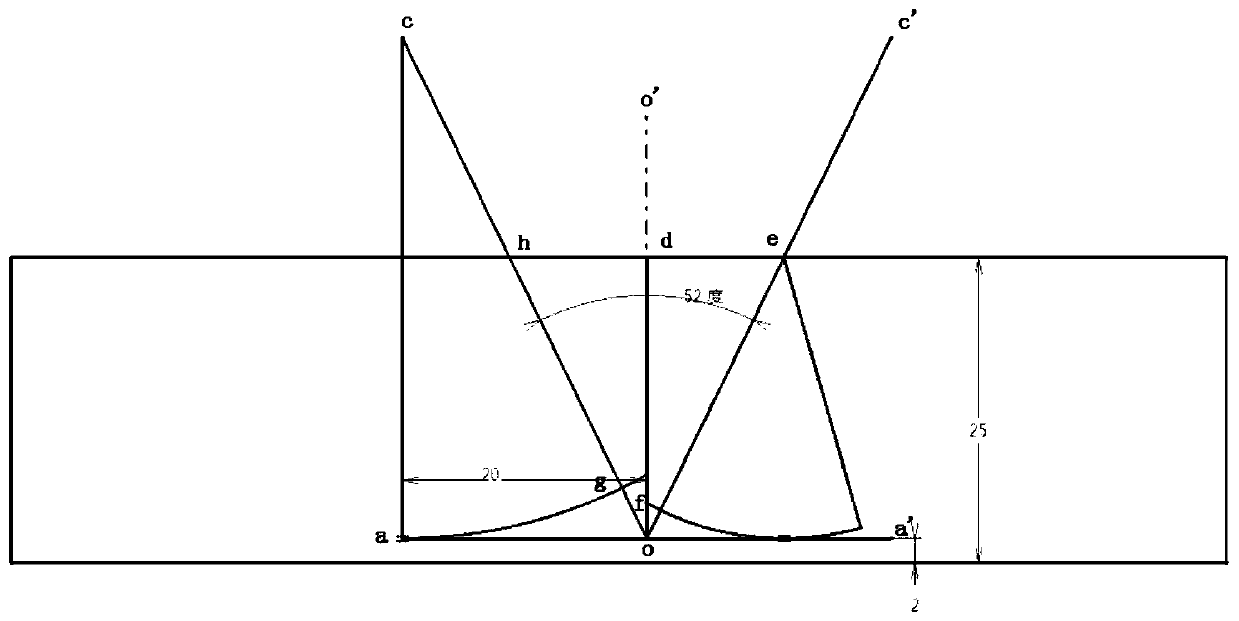

[0021] In this embodiment, the steps of drawing a "T"-shaped cutting track are described by bending a rectangular steel pipe with a size of 25*25mm*1.5mm at 128°:

[0022] Step 1: Since the wall thickness of the steel pipe is 1.5mm, draw a straight line aa' on a surface perpendicular to the bending surface at a distance of 2mm from one edge of the steel pipe.

[0023] Step 2: Make the bending center line oo' intersect aa' at point o, and intersect the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com