Piano sound board and manufacturing method thereof

A soundboard and jigsaw technology, applied to stringed instruments, instruments, etc., can solve the problems of low utilization rate of wood, time-consuming processing, sound quality affected by soundboard, etc., to achieve the effect of reducing factory capital occupation, using more species of timber trees, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

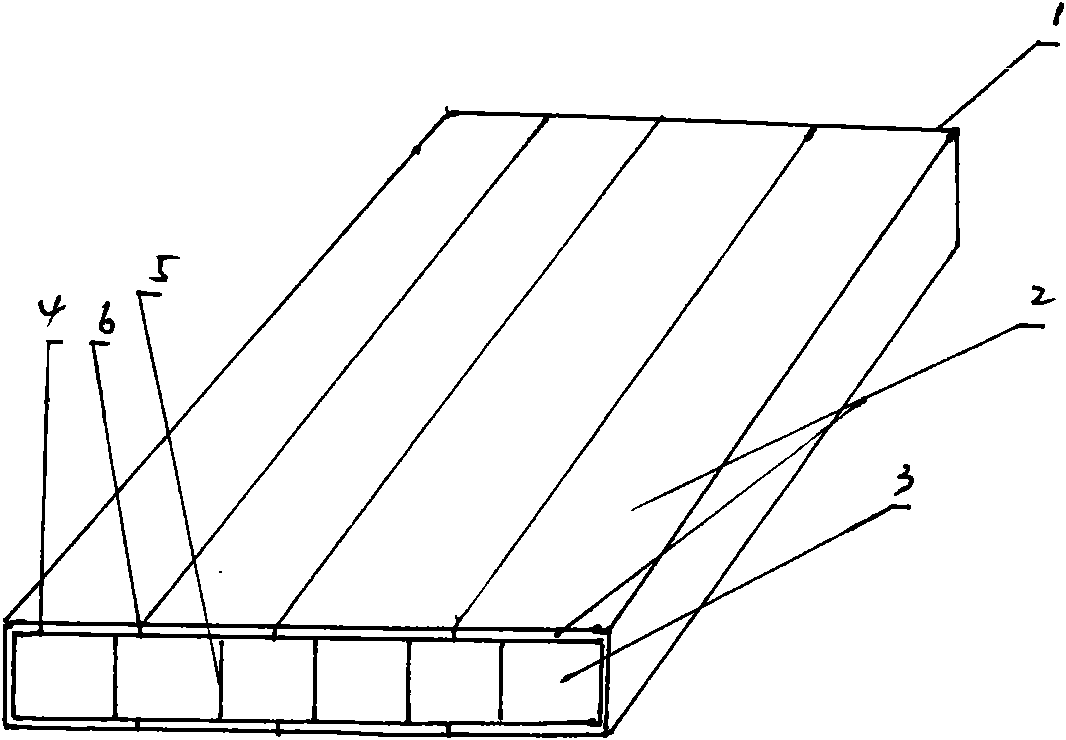

Image

Examples

Embodiment 1

[0020] Embodiment 1: A kind of soundboard, comprises inner core solid wood panel and upper and lower surface sliced veneer, and inner core solid wood panel is spruce or redwood, or radially sliced veneer of fir wood, sliced The veneer and the solid wood panel and the solid wood strips of the solid wood panel are bonded with an adhesive. The inner core solid wood panel processing adopts the selected wood, sawing or quarter-cutting the board, spraying water steam in the drying kiln, spraying wet-drying and conditioning for many times to obtain the board with a moisture content of 6-10% , sawing after curing or inner core board for sound board.

Embodiment 2

[0021] Embodiment 2: a kind of manufacturing method of soundboard, comprises the following steps:

[0022] a: sliced veneer processing. Choose spruce, red pine, or fir with few knots and no decay, and saw it into wooden squares for radial slicing. The wood with more oil is boiled and degreased, sliced, and dried and sliced veneer until the moisture content is 6. -10% Trimming to obtain knotless radial sliced veneer strips.

[0023] b: core board processing. Choose spruce, red pine, or fir with uniform material, no knots, and no decay. Logs are radially sawn into planks for soundboards. The planks with a lot of oil are boiled and degreased; the planks are sent to the drying room to dry, and spray water when dry Steam, wet spraying——drying repeatedly, tempering treatment, treatment time 15-20 days, moisture content 6-10%; health preservation, put the dried planks into the health care room, control the relative humidity of the health care room, Keep the quarter-cut plank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com