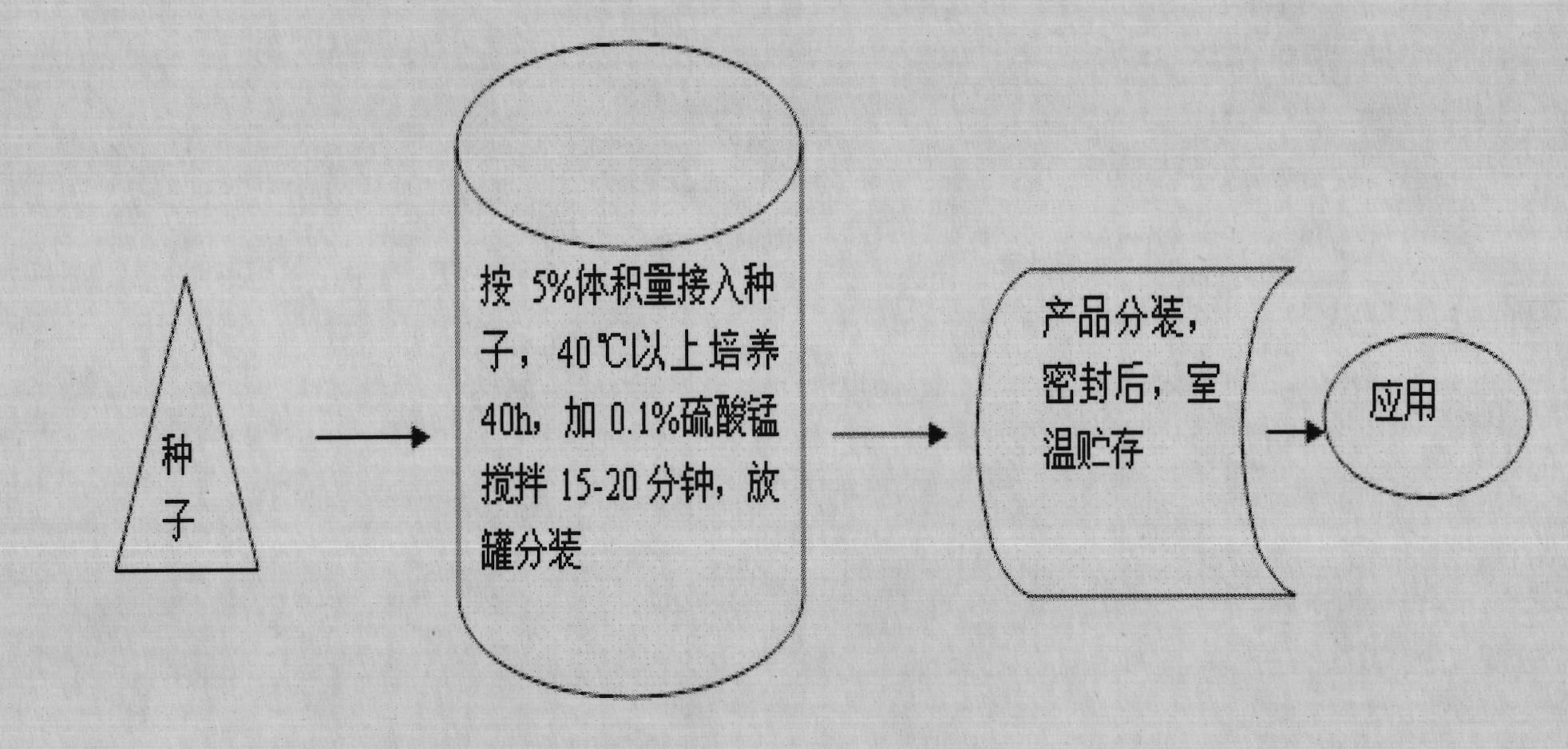

Production process of microbial preparation for baking tobacco leaves

A microbial preparation and production process technology, applied in the field of microbial preparation production technology, can solve the problem of huge energy consumption of equipment, and achieve the effects of saving investment and energy consumption, strong resistance to harsh environments, and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Fermentation process parameters of bacterial strain YN91 and bacterial strains YN114, YN113, YN104 of the present invention. The fermentation medium of strain YN91 is: wheat bran 1.5%, urea 0.5%, NaCl 0.5%. Fermentation process parameters: temperature 50°C, time 18h, stirring speed 125rpm. The enzyme activity level is around 6960U / mL. The fermentation medium of strain YN114 is: soluble starch 0.5%, beef extract 1.0%, CaCO 3 0.3%. Fermentation process parameters: temperature 43°C, time 36h, stirring speed 125rpm. The enzyme activity level is around 28(U / mL). The fermentation parameters of strains YN113 and YN104 were the same as those of YN114.

[0025] The specific method is as follows: culture medium preparation, take 5-15mL of the waste tobacco leaf extraction stock solution soaked for 2-3 days in a 500mL triangular flask, add 95-85mL of tap water, add 2.5g of agar powder, the pH is natural, after shaking well, use 15 lb. Autoclave for 30 minutes. Af...

Embodiment 2

[0033] Example 2: In a 50L Bio-automatic fermenter, use the "Method for High Temperature Separation of Microorganisms on the Surface of Tobacco Leaves with Pure Tobacco Leach Liquid Solid Plate", then 150mL of the protease-producing high-temperature bacterial strain YN114 seed culture solution isolated in step A was inoculated into Put 2.4Kg of crushed waste tobacco leaves and 30L of tap water into the sterilized medium, rotate at 120rpm, cultivate at 45±5°C, add 30g of manganese sulfate that was filtered and sterilized after 46 hours of fermentation, stir for 2 hours, put The cans are divided into plastic bottles and sealed for later use. The product is stored for half a year, and the number of viable bacteria is greater than 500×10 8 cfu / mL, protease activity was 28.30U / mL. Others are the same as the examples.

Embodiment 3

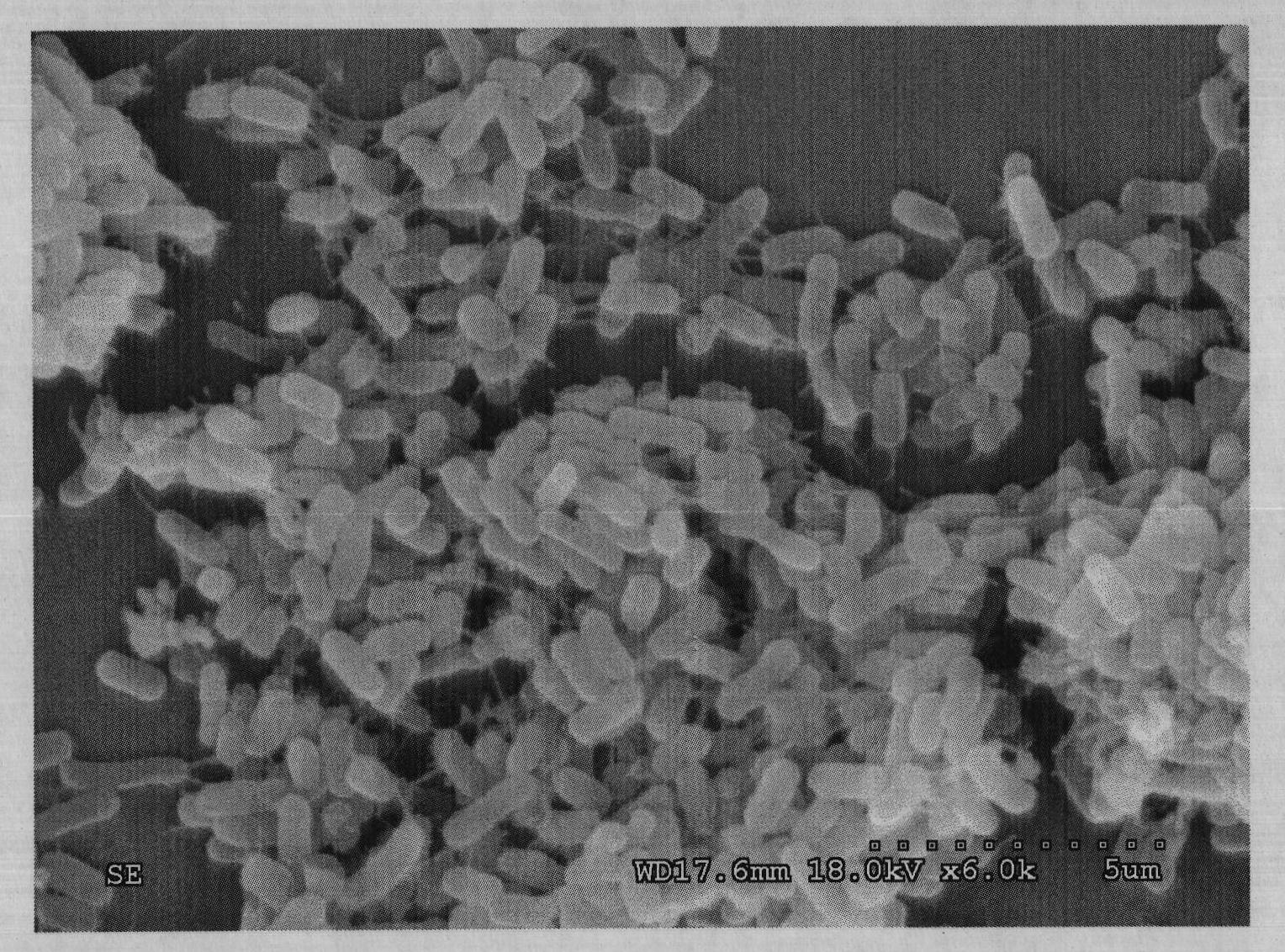

[0034] Example 3: In a 50L Bio-automatic fermenter, use the "Method for High Temperature Separation of Microorganisms on the Surface of Tobacco Leaves from Pure Tobacco Leach Liquid Solid Plate", then 150mL of the protease-producing high-temperature bacterial strain YN113 liquid isolated in step A is inoculated into 2.4 Kg crushed discarded tobacco leaves and 30L tap water sterilized culture medium, rotating speed 120rpm, culture temperature 50±5°C, when fermented to 40 hours, add filter-sterilized manganese sulfate 30g, stir for 2 hours, put into tank and divide Put it into a plastic bottle and seal it for later use. The storage period of the product is one year, and the number of viable bacteria is greater than 500×10 8 cfu / mL, protease activity was 24.10U / mL. It can still be metabolized during the curing process, improving the quality of cured tobacco leaves such as image 3 shown. The present invention adds 0.1%-0.5% MnSO to the fermentation liquid before the end of fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com