Cheese winding density measuring method and device

A density measurement and package yarn technology, which is applied in the field of package yarn winding density measurement method and device, can solve the problems of cumbersome process, poor accuracy, human injury, etc., and achieve simple measurement process, accurate winding density and safety of operators Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A method for measuring package winding density, such as figure 1 As shown, the cheese is composed of the yarn bobbin 3 and the yarn 2 wound on the bobbin. The volume of the yarn in the bobbin is obtained through simulation calculation, and the weight of the yarn in the bobbin is obtained through measurement and calculation. Obtain the winding density of the cheese by volume;

[0077] The steps of simulation calculation are as follows:

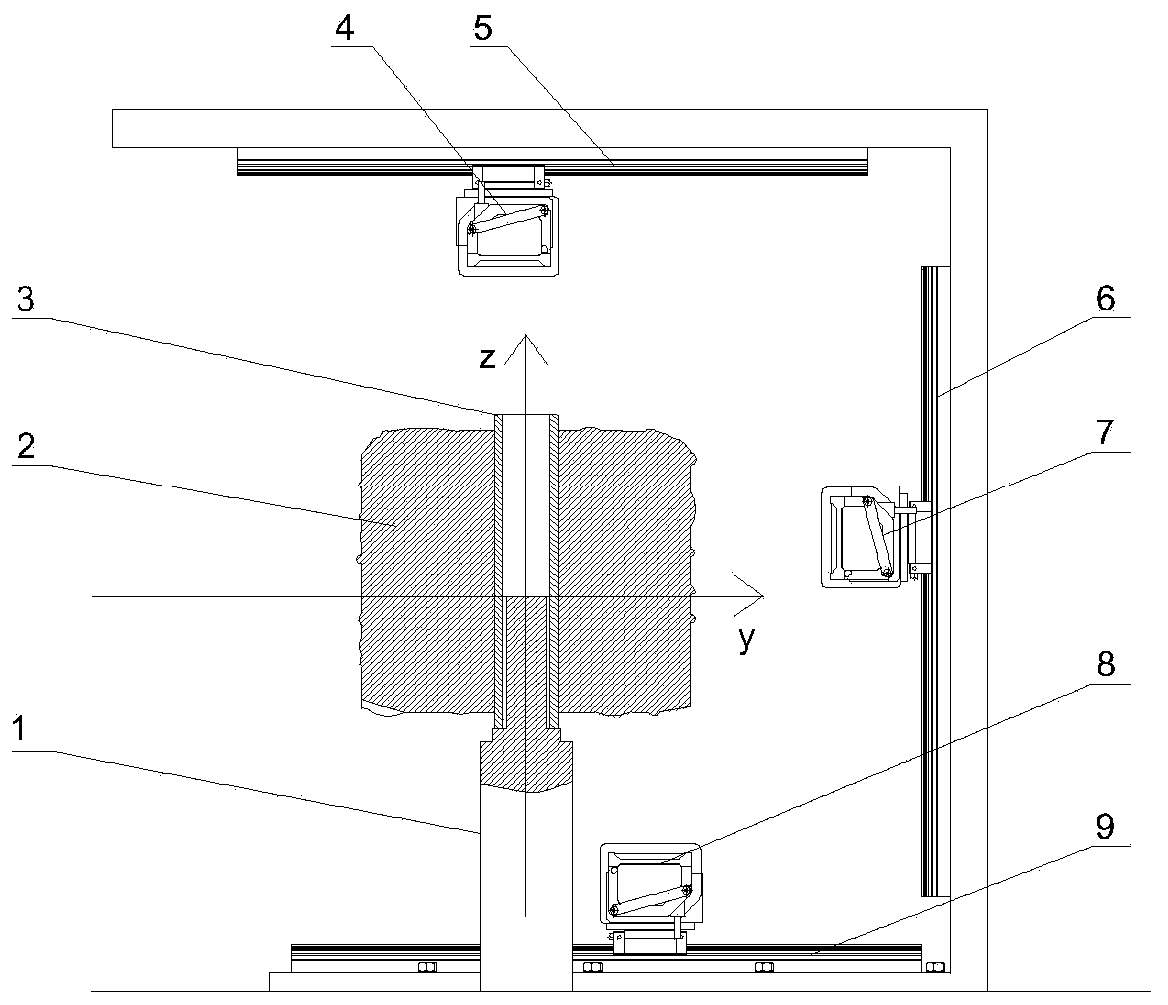

[0078] (1) Establish a rectangular coordinate system with the central axis of the yarn bobbin as the coordinate axis, such as image 3 shown;

[0079] (2) Collect the coordinates of multiple points arranged at equal intervals on lines a, b, and c, such as Figure 4 As shown, the yarn is wound into a hollow rotating body, and the rotating body is a cylinder or a circular platform. The lines a, b, and c are respectively corresponding to the intersection lines of the upper end surface, side surface, lower end surface of the rotating body...

Embodiment 2

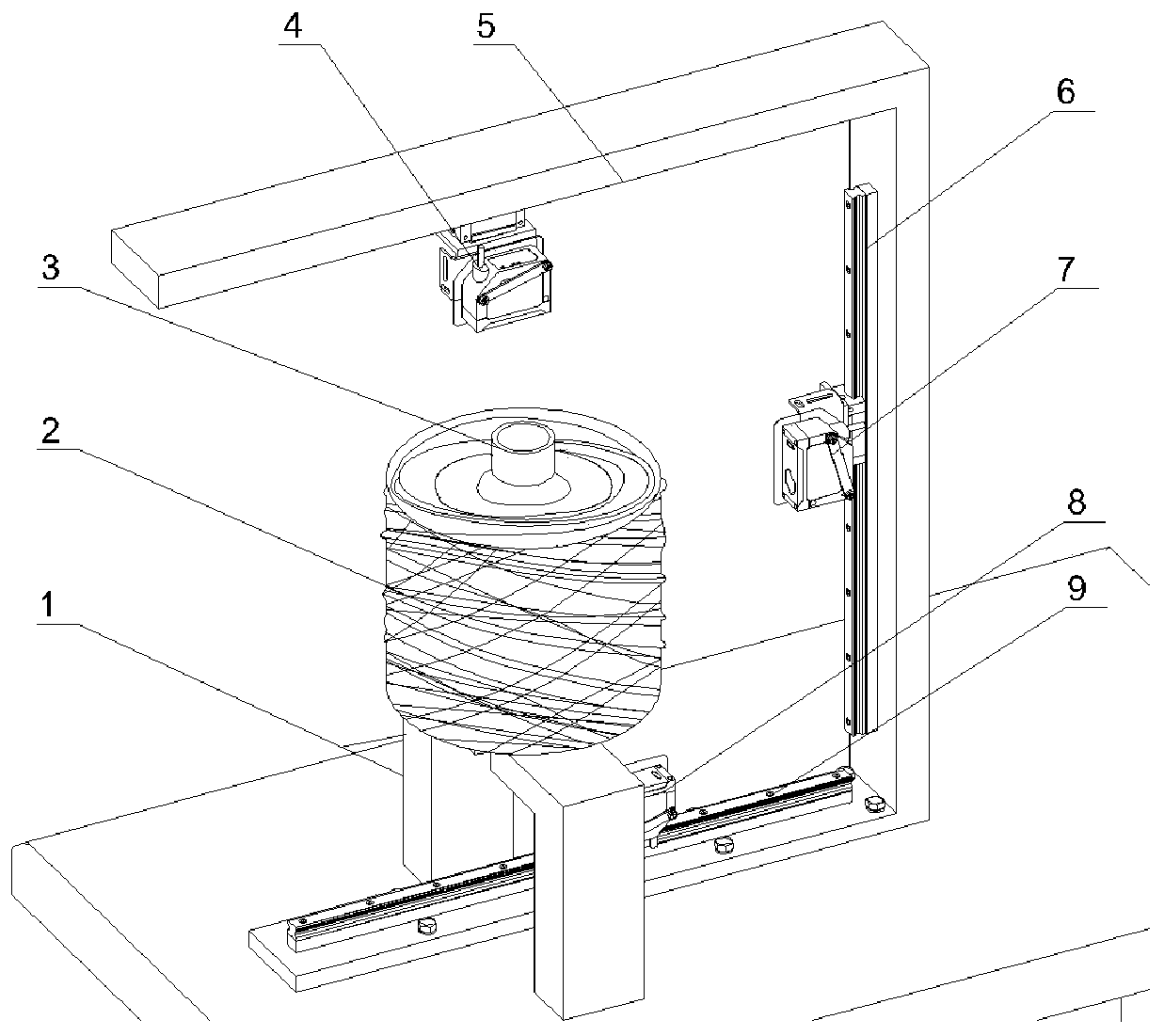

[0089] Adopt the cheese winding density measuring device of a kind of cheese winding density measuring method as described in embodiment 1, such as figure 2 As shown, it consists of bobbin fixing device 1, distance measuring device I 4, distance measuring device II 7, distance measuring device III 8 and fixing / driving device;

[0090] Yarn bobbin fixing device 1 such as Figure 7 As shown, it is used to fix the bobbin, the bobbin fixing device 1 is partially intercepted frame structure, The shaped frame is composed of a 匚-shaped frame with the opening direction downward and a cylinder vertically connected to the upper surface of the 匚-shaped frame. The interception refers to the interception by two mutually parallel planes, and the two planes are located on both sides of the central axis of the cylinder. Parallel to the central axis of the cylinder, and the distance between the two is smaller than the diameter of the cylinder; the yarn tube is placed on the cylinder, and ...

Embodiment 3

[0108] A method for measuring the winding density of cheese is basically the same as in Example 1, except that the difference is in step (2) and step (3);

[0109] Step (2) is: collect the coordinates of multiple points on the lines a and c, wind the yarn into a hollow rotating body, the rotating body is a cylinder or a circular platform, and the lines a and c correspond to the upper end surface, the lower end surface and the half surface of the rotating body respectively. The intersection line of the section Q, one side of the half section Q coincides with the central axis of the yarn bobbin, and is located on the plane where the Cartesian coordinate system is located at the same time. The default line of intersection is a slanted line or a straight line, and it is not necessary to collect the coordinates of multiple points on line b at this time;

[0110] Step (3) is: fitting the multiple points on the lines a and c to obtain the corresponding fitting curves a*, c* and fitti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com