Self-hardening rubber asphalt paint

A kind of rubber asphalt, self-hardening technology, applied in the field of coatings, can solve the problems of low cloud point, self-hardening rubber asphalt coatings can not meet the construction process requirements, strict selection of components and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

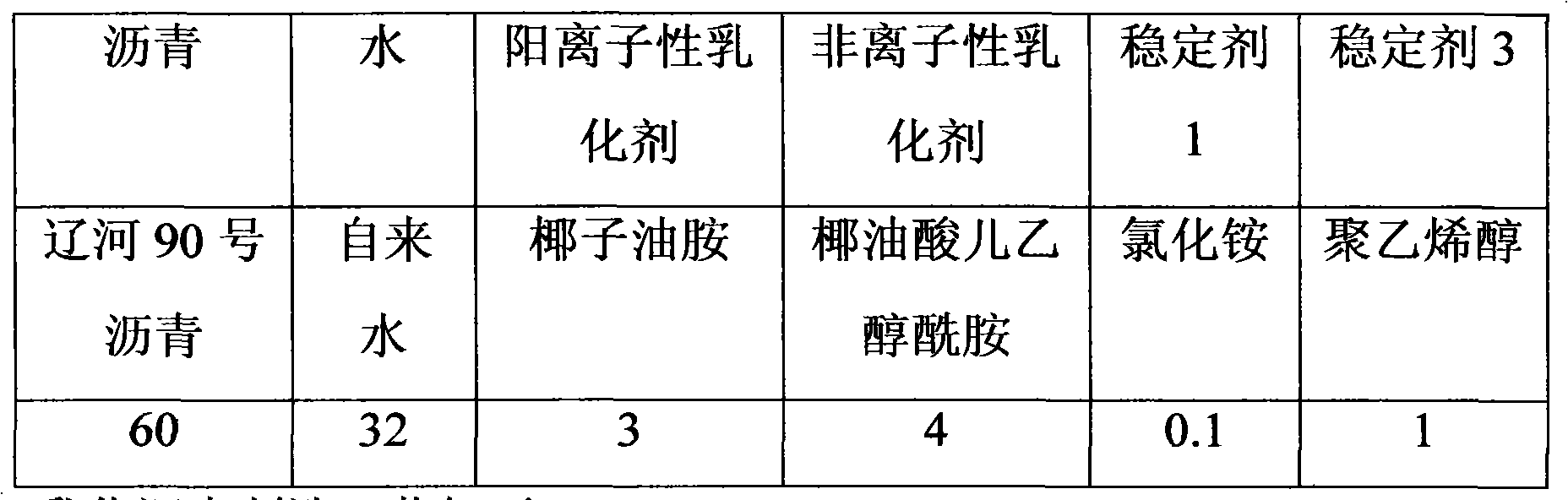

[0041] The emulsified asphalt raw materials in the invented product are proportioned according to the following (Table 1) (weight ratio, the same below):

[0042] Table 1 Emulsified asphalt formula table (100 parts of emulsified asphalt)

[0043]

[0044] The manufacturing process of emulsified asphalt is as follows:

[0045] A. Dehydrate the asphalt at 110°C-130°C for 1 hour to 2 hours, then gently heat it to 130°C-160°C, and use it after measurement;

[0046] B. Heat the tap water to 45℃-65℃, and use it after measurement;

[0047] C. Add the emulsifier and stabilizer to the standby hot water, stir evenly to make an emulsified aqueous solution, and control the temperature to 45°C-65°C for standby;

[0048] D. Turn on the emulsifier system, pour the emulsified aqueous solution that meets the temperature requirements into the emulsification, and immediately pour the hot asphalt that meets the temperature requirements, and the preparation of the emulsified asphalt that meets the requiremen...

Embodiment 2

[0055] Mix the emulsified asphalt raw materials according to the following (Table 3) (weight ratio, the same below):

[0056] Table 3 Emulsified asphalt formula table (100 parts of emulsified asphalt)

[0057]

[0058] The emulsified asphalt manufacturing process of Example 2 is as Example 1

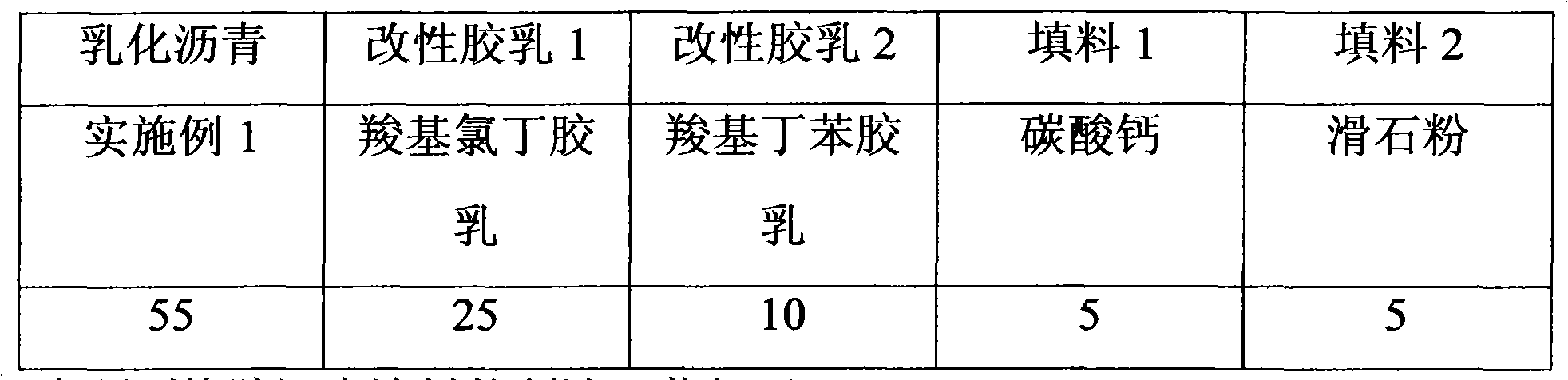

[0059] Then mix the raw materials in the coating according to the following (table 4) ratio (weight ratio, the same below):

[0060] Table 4 Self-hardening rubber asphalt paint (100 parts paint)

[0061]

[0062] The manufacturing process of the self-hardening rubber asphalt coating of Example 2 is as in Example 1.

Embodiment 3

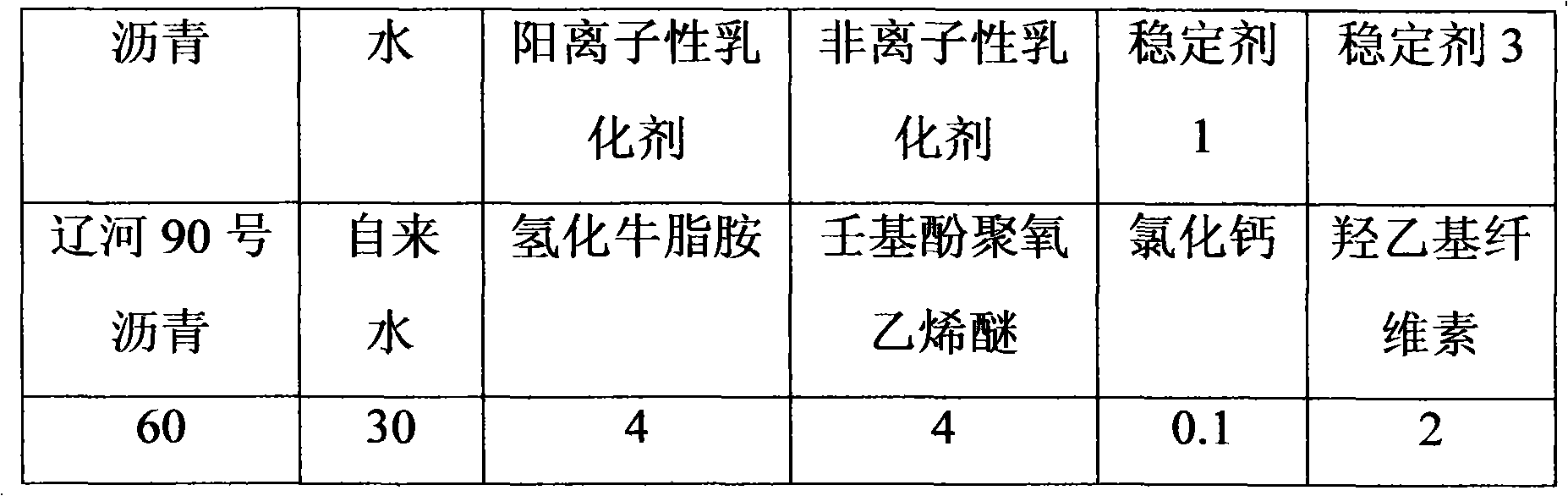

[0064] The emulsified asphalt raw materials are proportioned according to the following (Table 5) (weight ratio, the same below):

[0065] Table 5 Emulsified asphalt formula table (100 parts of emulsified asphalt)

[0066]

[0067] The emulsified asphalt manufacturing process of Example 3 is as Example 1

[0068] Then mix the raw materials in the coating according to the following (table 6) ratio (weight ratio, the same below):

[0069] Table 6 Self-hardening rubber asphalt paint (100 parts paint)

[0070] Emulsified asphalt

[0071] The manufacturing process of the self-hardening rubber asphalt coating of Example 3 is as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com