Seawater desalinization pretreatment method by using bipolar membrane through reverse osmosis process

A technology of reverse osmosis and treatment method, which is applied in the field of pretreatment in the process of seawater desalination, to achieve the effect of convenient operation, solving scaling and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

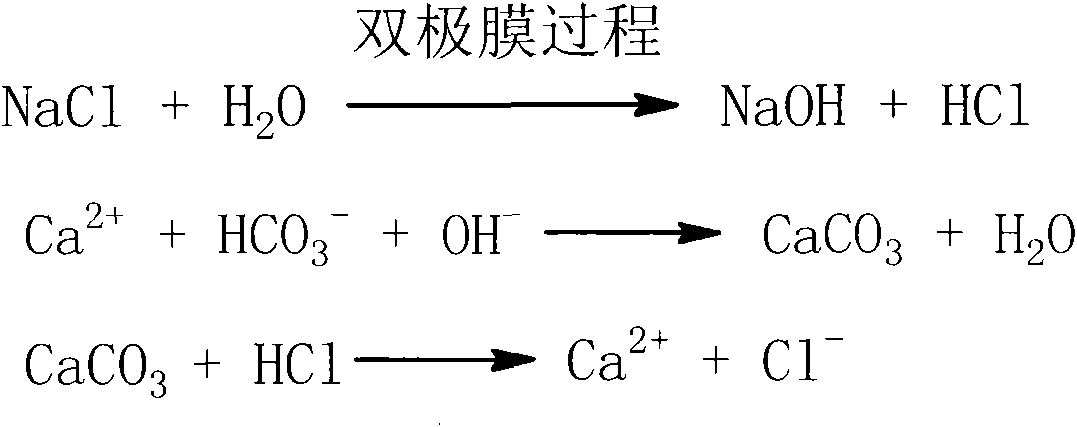

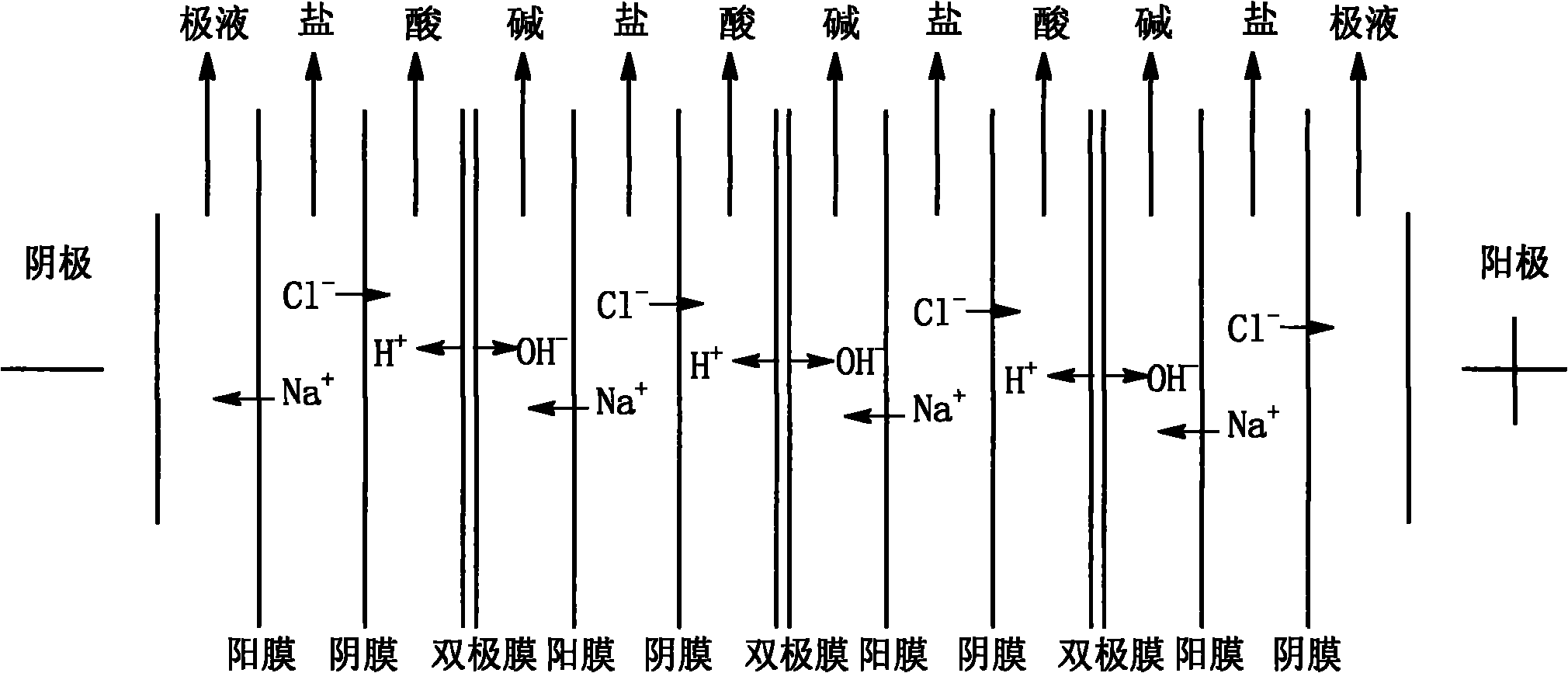

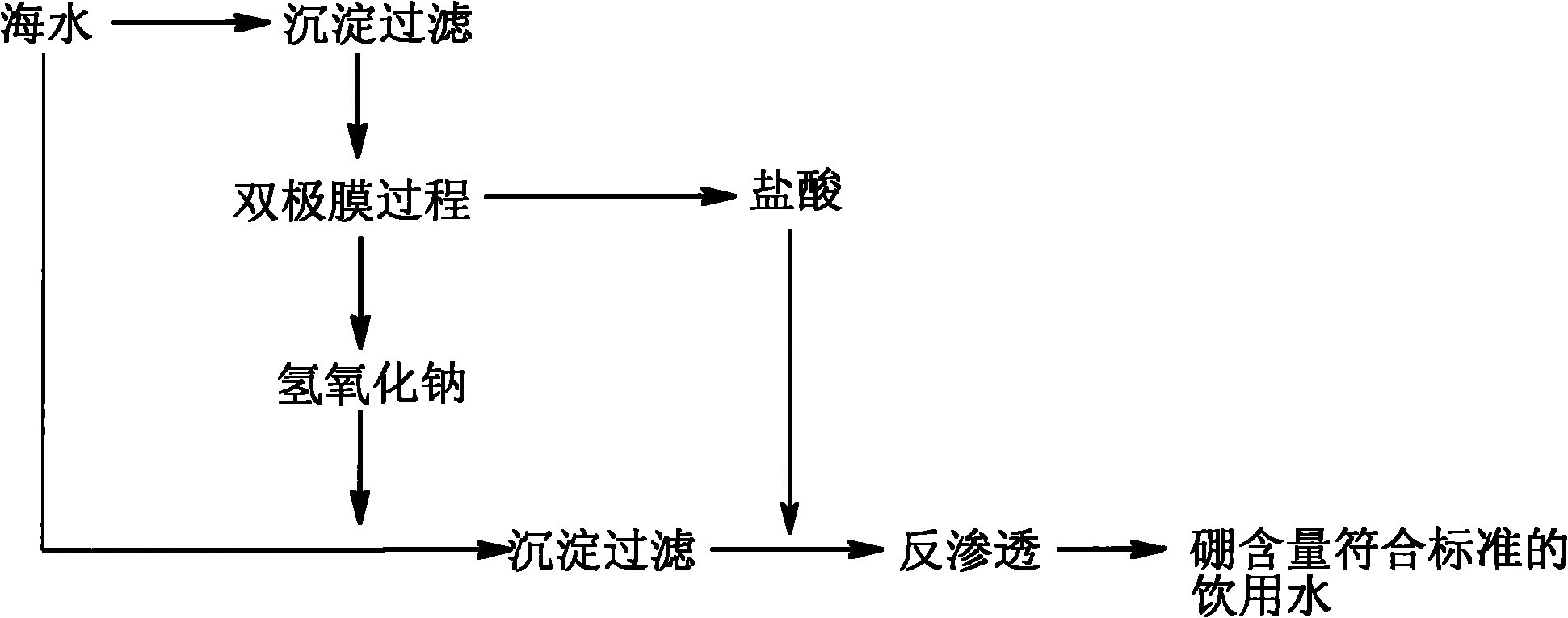

Method used

Image

Examples

Embodiment 1

[0038] The seawater that has undergone flocculation, sedimentation and sand filtration is used as the influent, the bipolar device is BMP2-500 device, 40 pieces of 200*400 bipolar membranes are used, the positive membrane adopts 40 pieces of CSO-bivalent separation membrane, and the negative membrane adopts AMV membrane, 80 sheets of 200*400 elastic separators, titanium-coated ruthenium electrodes for the cathode, and platinum electrodes for the anode. The current density adopts 1000A / m 2 , the flow velocity on the membrane surface is 5cm / s, 3% sodium sulfate solution is used as the polar liquid, and the concentration of the acid solution in the acid chamber or the lye in the alkali chamber reaches about 10% by means of partial circulation. The lye in the alkali chamber is added to the original seawater with a metering pump at a rate of 10mL of lye per liter of seawater, so that the pH of the seawater rises to 10.4. Finally, after filtering with a 0.45 micron microfiltration ...

Embodiment 2

[0040] The seawater that has undergone flocculation, sedimentation and sand filtration is used as the influent, and the bipolar device is BMP2-2500, using 20 pieces of 400*800 bipolar membranes, and 20 pairs of one-bivalent separation membranes for the negative and positive membranes, 60 A 400*800 elastic separator, the negative electrode is a titanium-coated ruthenium electrode, and the anode is a platinum electrode. The current density is 500A / m 2 , the flow velocity on the membrane surface is 6cm / s, 5% sodium sulfate solution is used as the polar liquid, and the concentration of the acid solution in the acid chamber or the lye in the alkali chamber reaches about 5% by means of partial circulation. The lye in the alkali chamber is added into the original seawater with a metering pump at a ratio of 15 mL of lye per liter of seawater, so that the pH value of the seawater is raised to 10.3. Finally, after filtering with a 0.45 micron microfiltration membrane, the bipolar membr...

Embodiment 3

[0042] The seawater that has undergone flocculation sedimentation and sand filtration is used as the influent. The bipolar device is a BMP2-2500 device, and 20 bipolar membranes of 400*800 are used. The anion membrane and the anode membrane adopt a bivalent separation membrane CMO+AMV membrane 20 pairs, 60 sheets of 400*800 elastic separators, the negative electrodes are titanium coated ruthenium electrodes, and the anodes are platinum electrodes. The current density is 800A / m 2 , the flow velocity on the membrane surface is 7cm / s, 6% sodium sulfate solution is used as the polar liquid, and the concentration of the acid solution in the acid chamber or the lye in the alkali chamber reaches about 10% by means of partial circulation. Add the acid solution in the acid chamber of the bipolar membrane device directly into the raw seawater for acidification, and add the acid solution in the acid chamber of the bipolar membrane device into the raw seawater with a metering pump at a ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com