Abrasive-containing eraser

一种研磨材料、橡皮擦的技术,应用在擦除器、印刷、办公用品等方向,能够解决纸面起毛大等问题,达到生产性高、减轻依赖程度、实现成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11

[0094] Among the materials shown in Table 2, natural rubber, a softener, and a filler were kneaded in advance with a pressure kneader, and a rubber crosslinking agent was added using a roller to obtain a rubber kneaded product. The obtained rubber kneaded material was cut into pellets of about 5 mm square. Next, using a twin-screw extruder KZW-15TW-60 manufactured by Technobel Corporation (complete meshing type in the same direction, screw diameter 15mm, L / D=60), the rubber compound was supplied from a quantitative feeder at the compounding ratio shown in Table 2. The refining granules and biomass plastic granules were mixed under the condition that the screw rotation number was 400rpm. When the biomass plastic is PHBH (melting point 120°C), set the cylinder temperature at 120~160°C so that the kneading temperature is above the melting point and above the rubber crosslinking temperature (150°C), when it is レシチアH When it is -100 (melting point 164°C), set the cylinder temperat...

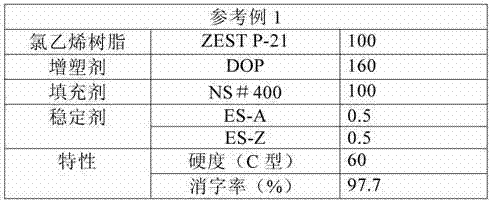

reference example 1

[0099] Reference example 1: Manufacture of vinyl chloride resin eraser

[0100] As shown in Table 3, the vinyl chloride resin, plasticizer, filler, and stabilizer were mixed and stirred to obtain a paste sol. After vacuum defoaming the obtained paste sol, it was poured into a molding mold (inner size: 100×100×10mm) kept at 130°C, heated for 26 minutes, cooled, taken out from the mold and cut to produce Vinyl chloride resin eraser (size 10×18×43mm).

[0101] The hardness and erasing rate of the obtained eraser were measured and evaluated in the same manner as in Examples 1 to 8. The results are shown in Table 3.

[0102] [table 3]

[0103]

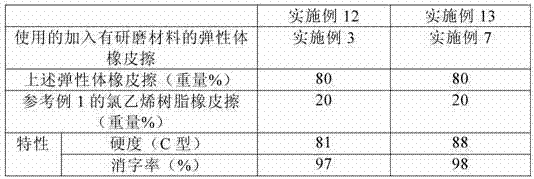

Embodiment 12~13

[0105] The elastomer eraser that adds grinding material obtained in embodiment 3, embodiment 7 and the vinyl chloride resin eraser obtained in reference example 1 are mixed with the mixing ratio (weight basis) shown in table 4, insulated to The mixture was kneaded for 5 minutes in a pressurized kneader at 120°C. The obtained composition was cooled, pulverized into pellets, extruded into a predetermined shape with a single-screw extruder, and cut to produce an eraser (size: 12×18×43 mm).

[0106] Measure and evaluate the hardness and the erasing rate of the obtained eraser with the method same as embodiment 1~11. The results are shown in Table 4.

[0107] [Table 4]

[0108]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com