Complementary metal oxide semiconductor (CMOS) active region isolating process

An active area and process technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of reducing the length of the bird's beak, complex process, poor surface morphology, etc. The effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific drawings and embodiments.

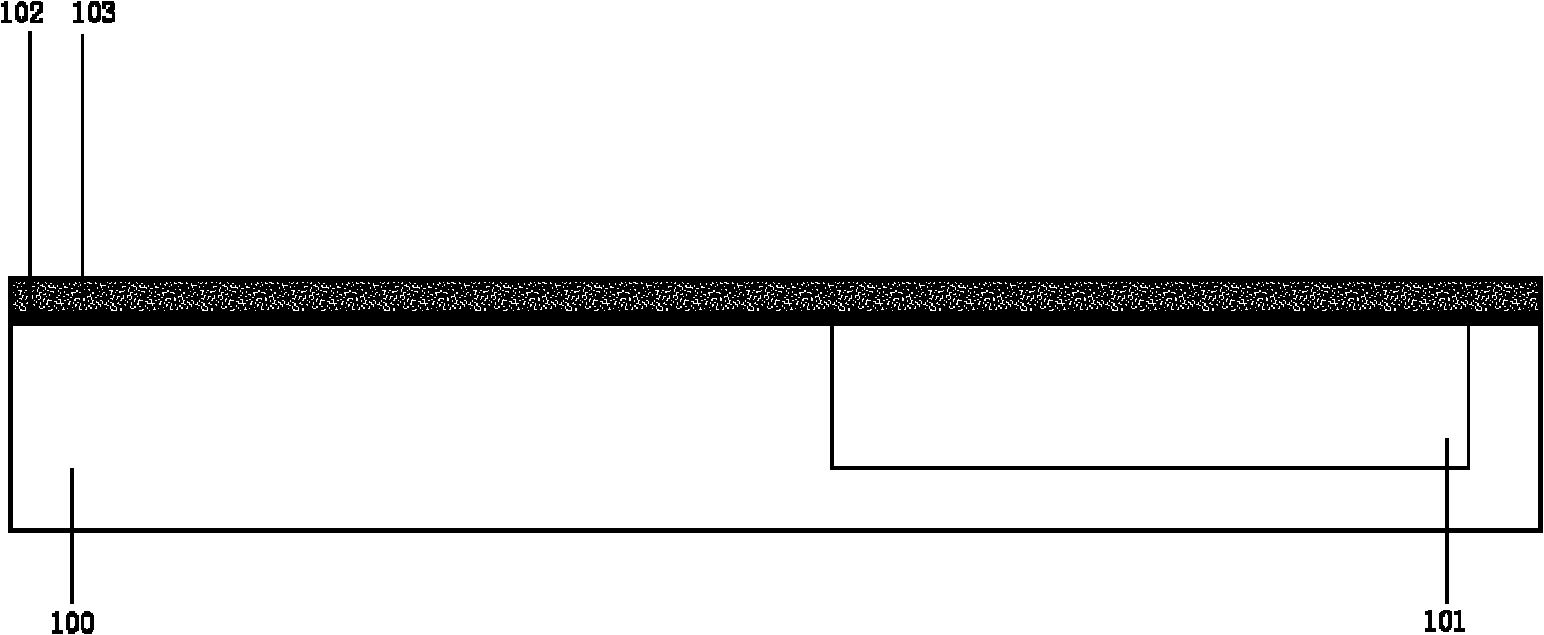

[0025] Such as figure 1 As shown in ~ 10: the present invention includes a first conductivity type substrate 100, a second conductivity type well region 101, a first barrier layer 102, a second barrier layer 103, a photoresist 104, a first spacer layer 105, a second The side wall layer 106 , the side wall 107 , the isolation layer 108 and the buried layer of silicon dioxide 109 .

[0026] In order to isolate the active area of the CMOS device, reduce the bird's beak after isolation and oxidation, reduce the isolation spacing of the active area, and make the field area and the active area flatter, the CMOS active area isolation process includes the following steps:

[0027] a. Provide a first conductivity type substrate 100, and form a second conductivity type well region 101 on the first conductivity type substrate 100, such as figure 1 shown;

[0028] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com