Method for forming crystal silicon film

A technology of amorphous silicon thin film and microcrystalline silicon thin film, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problems of low crystallization rate amorphous structure, high equipment cost, long process time, etc. , to achieve the effects of increasing capacity utilization, improving crystallization quality, and shortening process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Certain terms are used throughout the specification and preceding claims to refer to particular elements. It should be understood by those skilled in the art that manufacturers may refer to the same element by different terms. The specification and the scope of the preceding claims do not use the difference in name as the way to distinguish components, but the difference in function of the components as the basis for the difference. "Includes" or "comprises" mentioned throughout the specification and the preceding claims is an open term, so it should be interpreted as "including but not limited to".

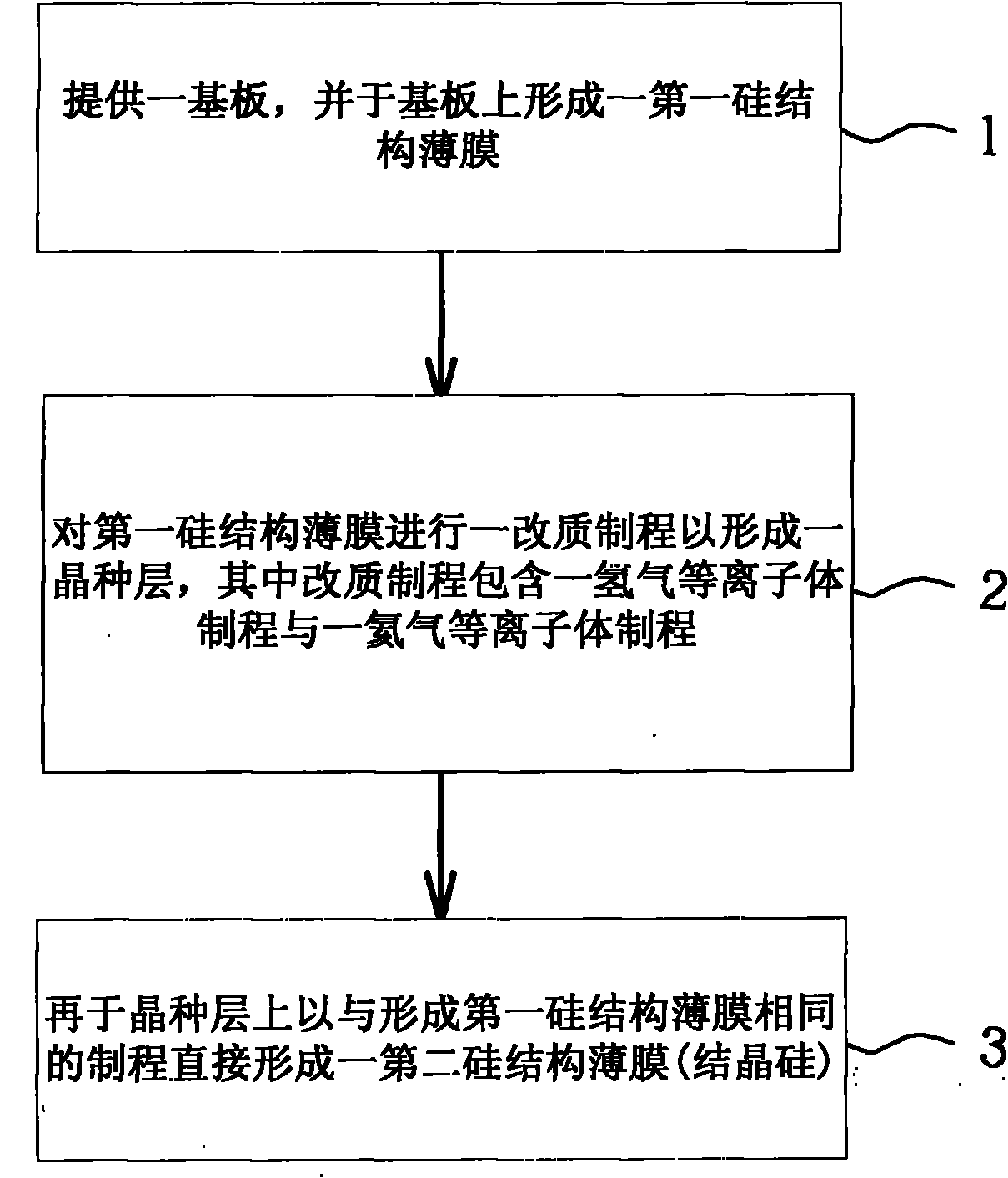

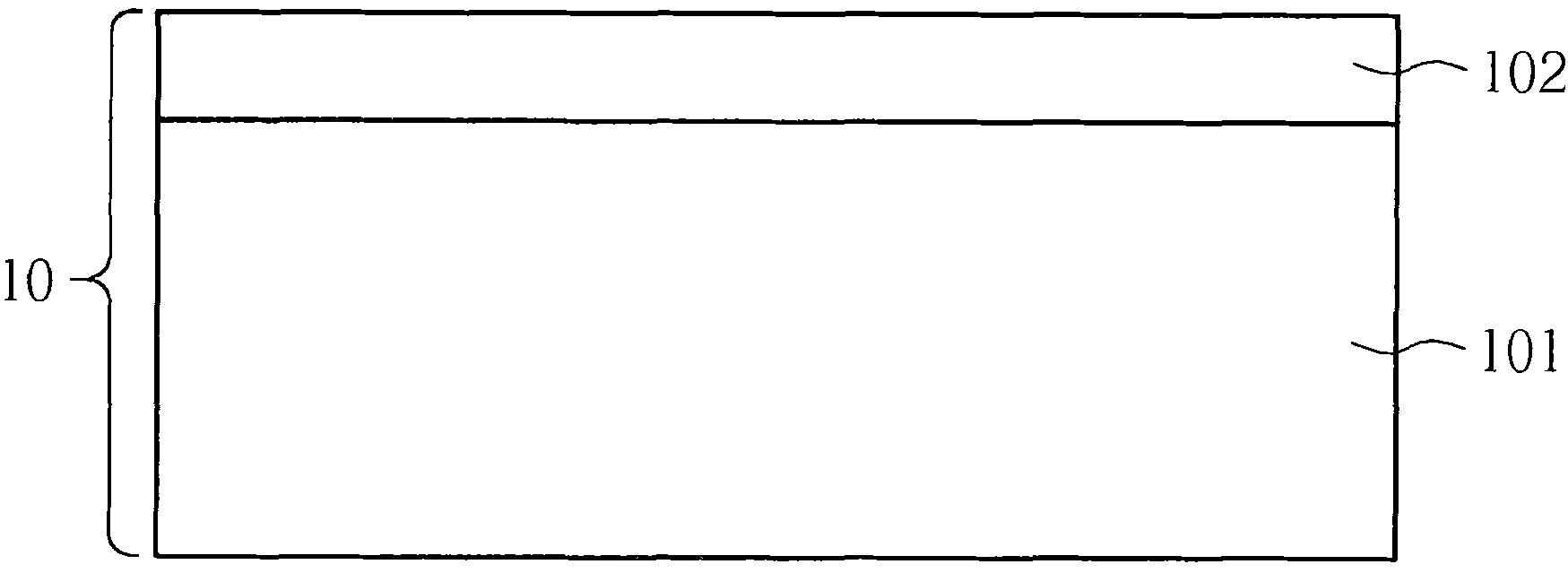

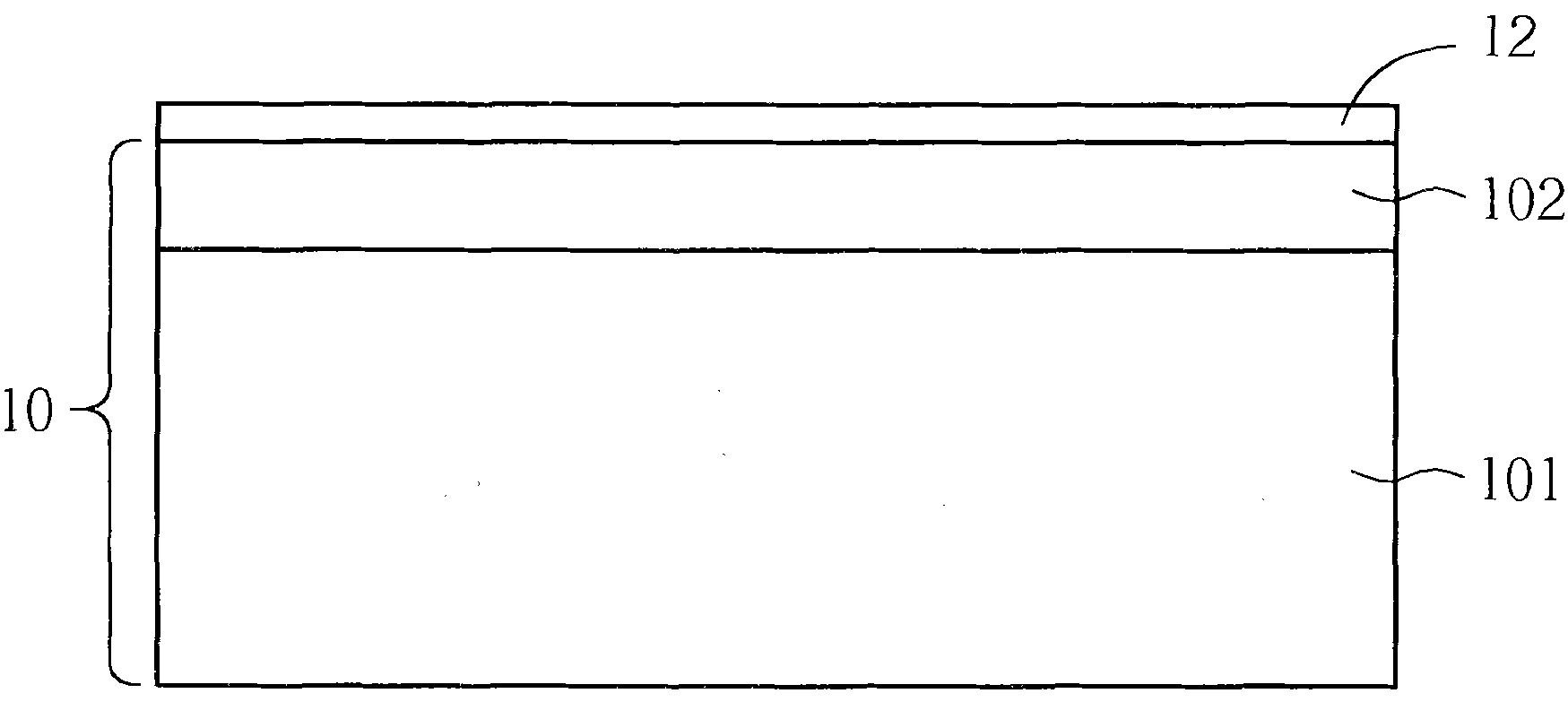

[0012] Please refer to figure 1 . figure 1 It is a schematic flow chart of the method for forming a crystalline silicon thin film of the present invention. like figure 1 As shown, step 1 provides a substrate, and forms a first silicon structure thin film on the substrate. Wherein, the first silicon structure film may include an amorphous silicon film, a microcrystalli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com