Through type rapid cut-off valve

A fast cut-off and straight-through technology, applied in the direction of valve lift, valve detail, valve device, etc., can solve the problems of wasting time, and achieve the effect of simple opening and closing structure, fast switching stroke and small flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

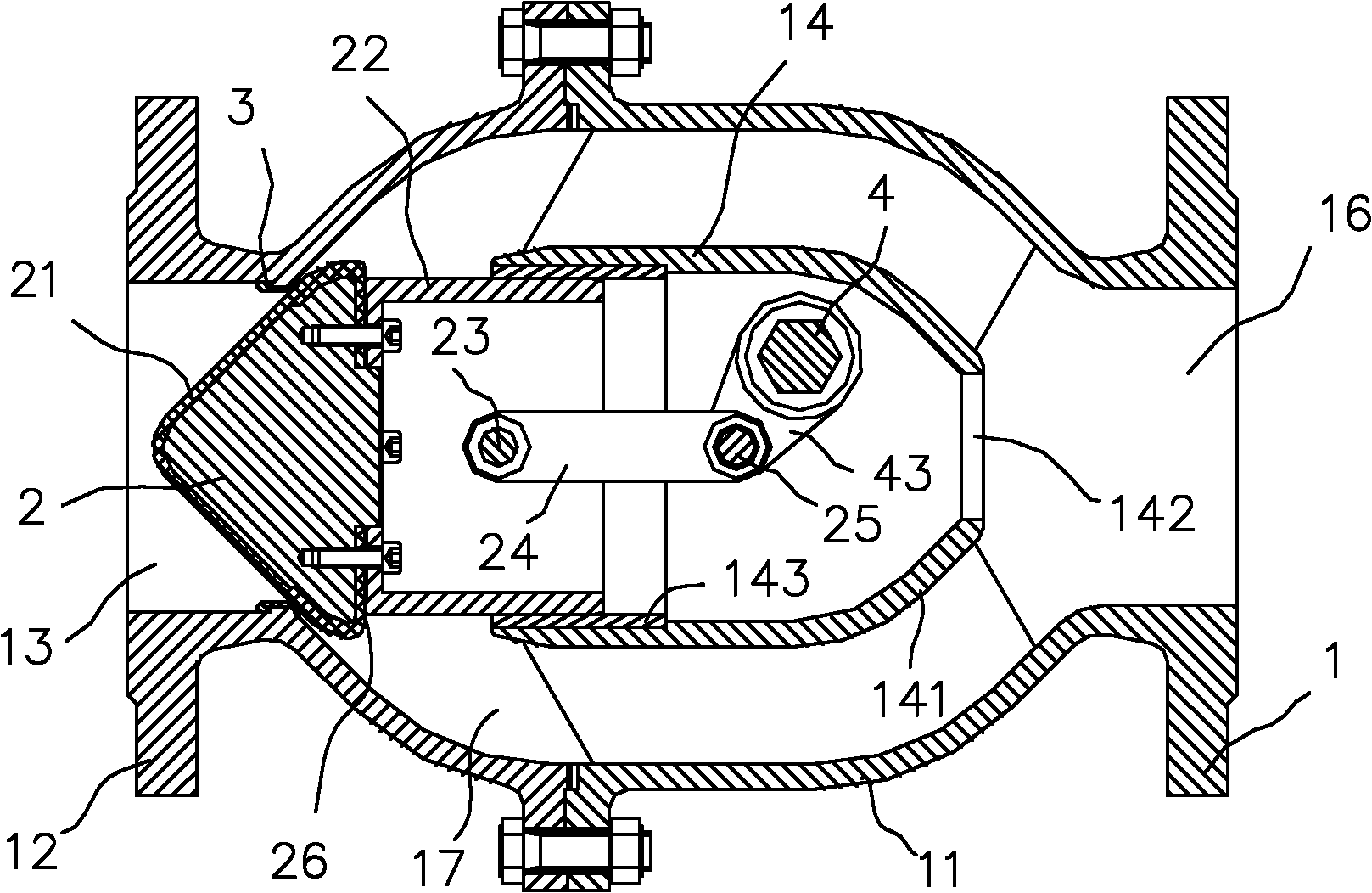

[0012] Such as figure 1 and figure 2 As shown, the present invention is made up of valve body 1, valve core 2, valve seat 3 and valve stem 4, and liquid inlet 13 and liquid outlet 16 are symmetrically arranged at the two ends of valve body 1 respectively, and valve body 1 is made up of main valve body 11 and side valve body 12, wherein the liquid inlet 13 is set on the side valve body 12, the liquid outlet 16 is set on the main valve body 11, the valve seat 3 is set at the liquid inlet end of the valve cavity 17, and the valve core 2 The front end has a conical surface 21 matching with the valve seat 3, the surface of the conical surface 21 at the front end of the valve core 2 is provided with a sealing surface formed of vulcanized rubber, and the rear end of the valve core 2 is fixed with a piston 22; 22 matched cylinder 14, the cylinder 14 is integrated with the main valve body 11 through the connecting rod 15, and the symmetry center of the cylinder 14 coincides with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com