Corrugated mechanism and distributing equipment

A shunt equipment and corrugated technology, applied in the direction of packaging automatic control, packaging, packaging protection, etc., can solve the problems of inaccurate quantitative counting, difficult shunt operation, low production efficiency, etc., to improve production efficiency, better shunt effect, and shorten production. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

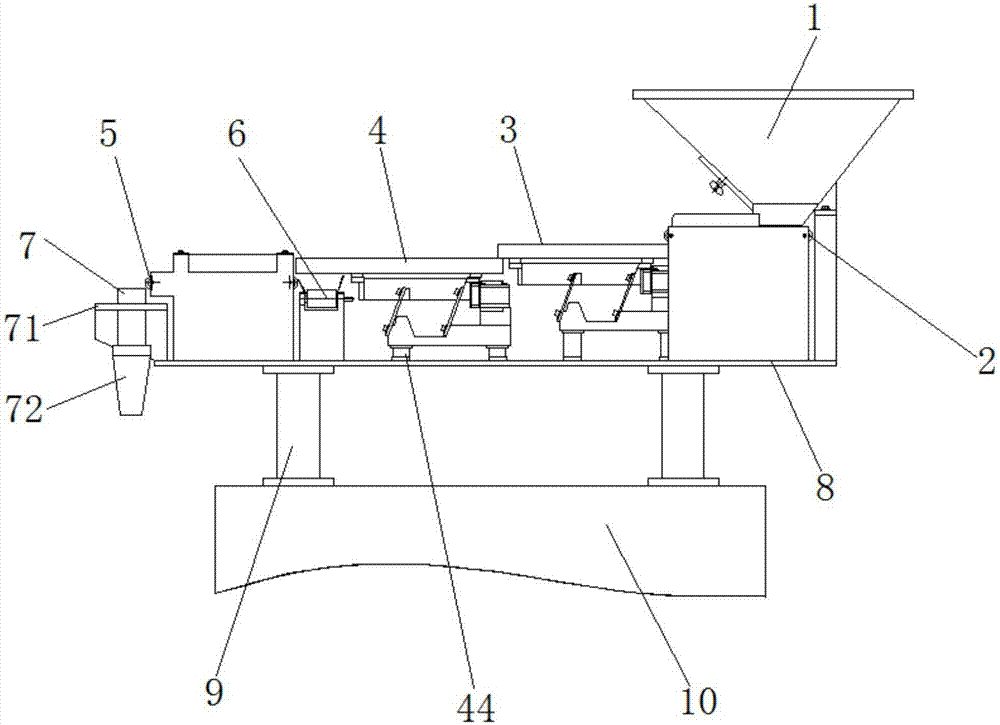

[0049] This embodiment is a shunt device, refer to figure 1 As shown, it includes a feed hopper 1, a first conveying mechanism 2, a first corrugating mechanism 3, a second corrugating mechanism 4, a second conveying mechanism 5 and an overlapping material collecting mechanism. The following are detailed introductions respectively.

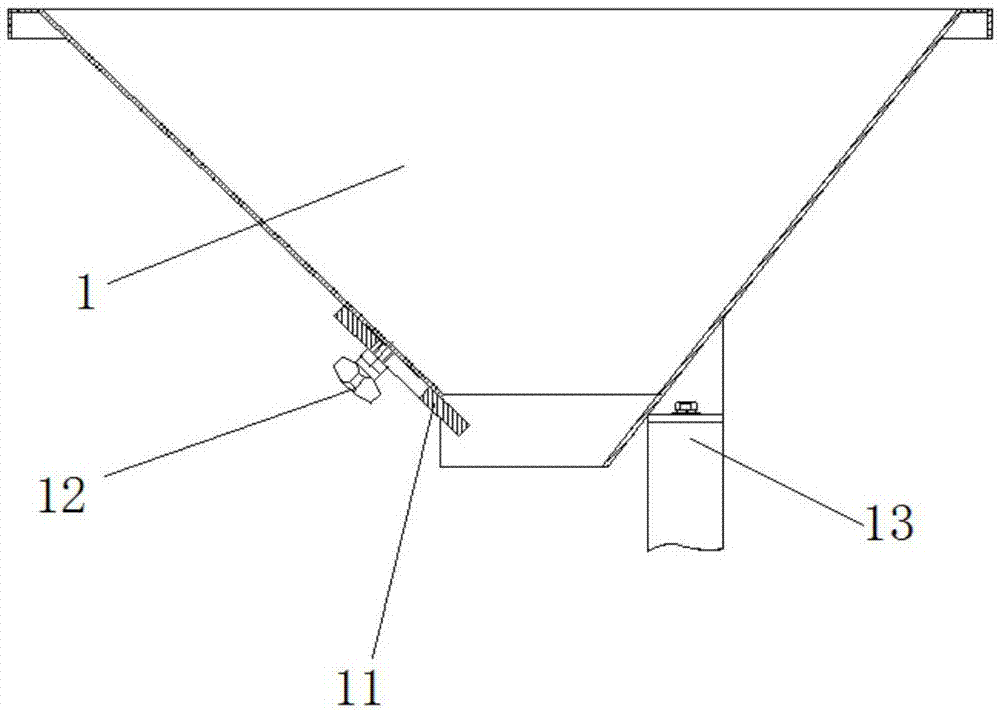

[0050] refer to figure 2 and image 3 As shown, the width of the inlet end of the feed hopper 1 is greater than the width of the outlet end, and the outlet end of the feed hopper 1 is fixedly connected with an adjustment device for adjusting the size of the outlet end of the feed hopper 1, so as to facilitate the adjustment of the amount of feed at one time, so as to avoid excessive Too many materials enter at the same time, blocking the outlet end of the feed hopper 1, making it impossible to feed materials to the next process in time.

[0051] It should be noted that the adjustment device includes an adjustment plate 11 fixedly connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com