Water jetting air pumping device

A technology of air extraction device and mounting plate, which is applied in the direction of jet pump, machine/engine, non-displacement pump, etc. It can solve the problems of pumping efficiency and other issues, so as to achieve the effect of good shunt effect, simple structure and stable pumping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

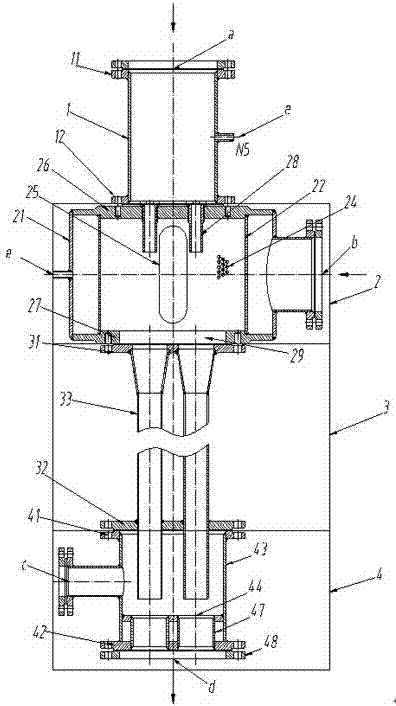

[0025] Such as figure 1 and figure 2 As shown, it includes an upper connecting pipe 1, an upper suction chamber 2, an intermediate throat pipe 3 and a lower diffusion chamber 4 which are arranged coaxially from top to bottom and communicate with each other; the upper and lower ends of the upper connecting pipe 1 respectively have an upper flange A11 With the lower flange A12, the upper end of the upper connecting pipe 1 has a water inlet a.

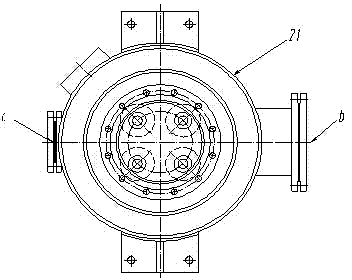

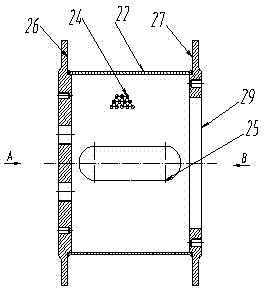

[0026] Such as image 3 As shown in -5, the upper suction chamber 2 includes an outer cylinder 21 and an annular flow divider 22 coaxially sleeved in the outer cylinder 21. The side wall of the outer cylinder 21 has an air inlet b; the annular flow divider The side wall of 22 is evenly distributed with a number of distribution small holes 24, and a pair of symmetrically arranged large distribution holes 25 are also opened on the side wall, and a nozzle mounting plate 26 and a throat are respectively provided on the upper and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com