Drive unit of a transmission

A technology for transmission units and transmissions, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc., and can solve problems such as inability to accurately adjust lubricating oil, insufficient oil supply to roller bearings, and increased wear of roller bearings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

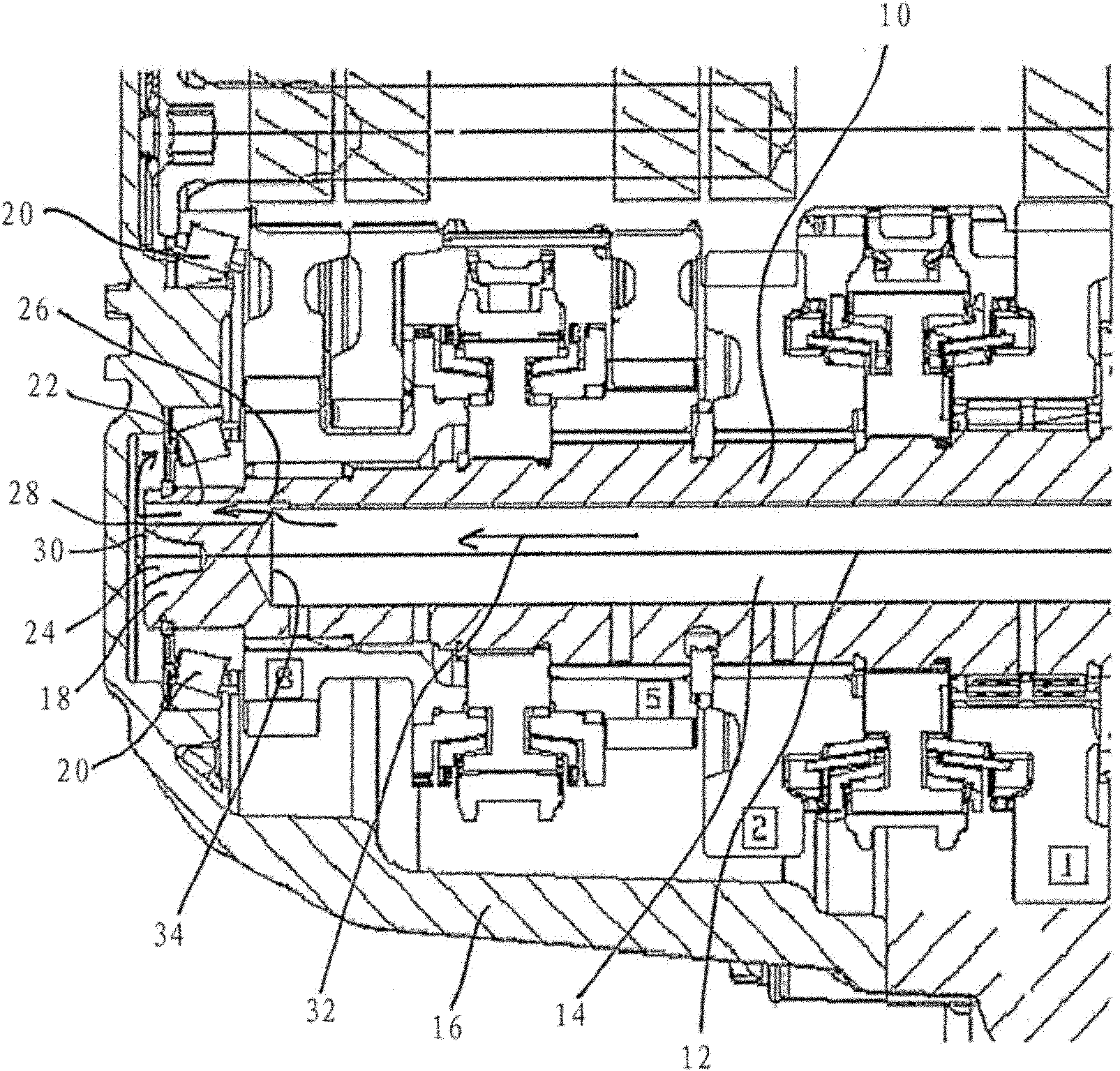

[0015] the only attached figure 1 A sectional view of a partial region of a transmission drive unit according to the invention is schematically shown. The transmission unit has a main shaft 10 with a bore 14 formed along its central axis 12 for the supply of lubricating oil. In this case, the central axis 12 of the spindle 10 corresponds to the central axis of the bore 14 . The main shaft 10 is mounted in a housing 16 , wherein this support is realized by two roller bearings 20 arranged on an end section 18 of the main shaft 10 . For the supply of lubricating oil from bore 14 , there is provided a lubricating oil supply line 22 which can transport lubricating oil from bore 14 to roller bearing 20 . The roller bearing 20 is here preferably designed as a tapered roller bearing. The central axis of the lubricating oil delivery pipe 22 is designed to be parallel to the central axis of the hole 14 , wherein the lubricating oil delivery pipe 22 is arranged on the main shaft 10 ec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com