Spindle motor

A technology of lead screw motor and screw lead screw, which is applied in the direction of electrical components, electromechanical devices, mechanical equipment, etc., can solve the problems of short service life and achieve the effect of reliable maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

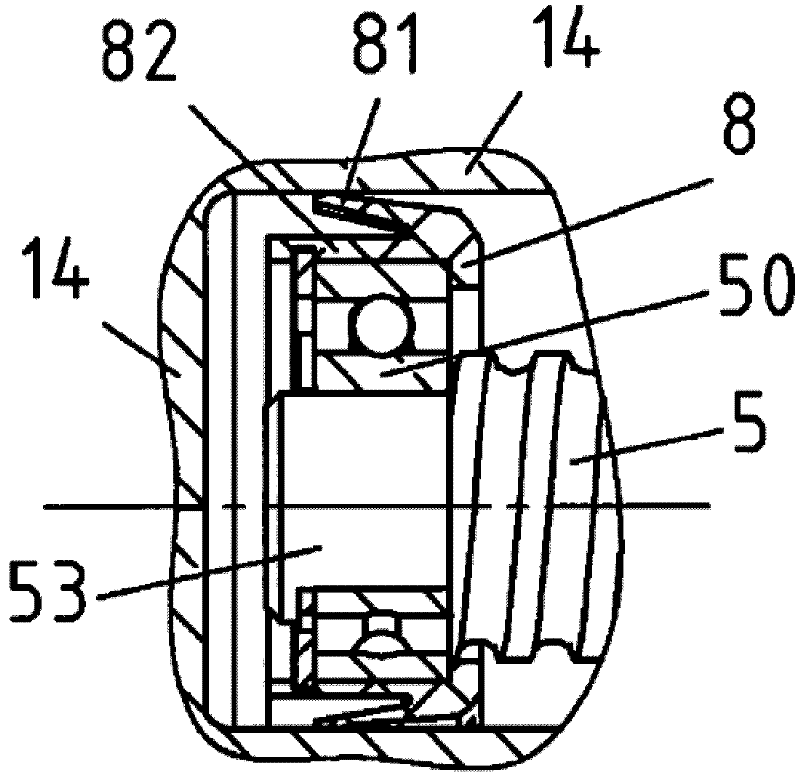

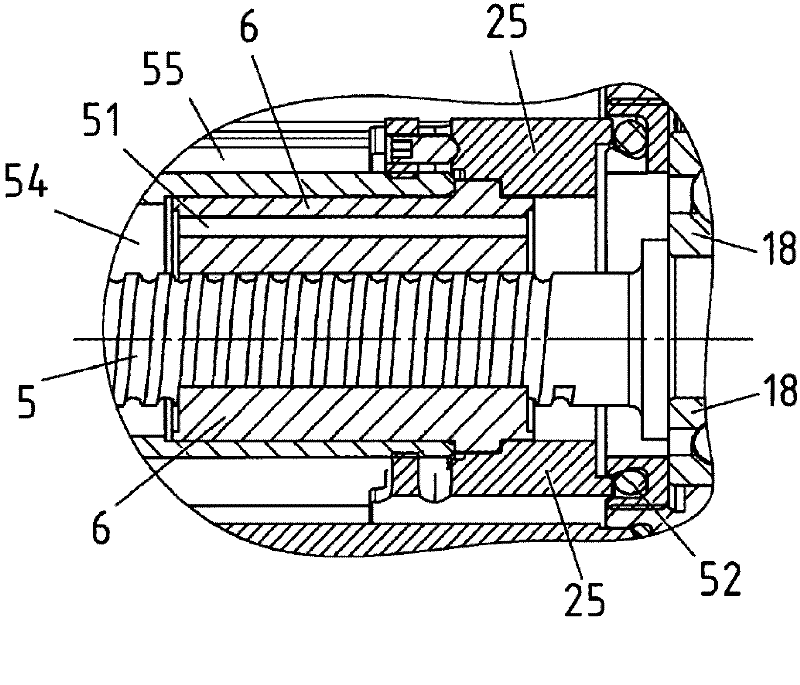

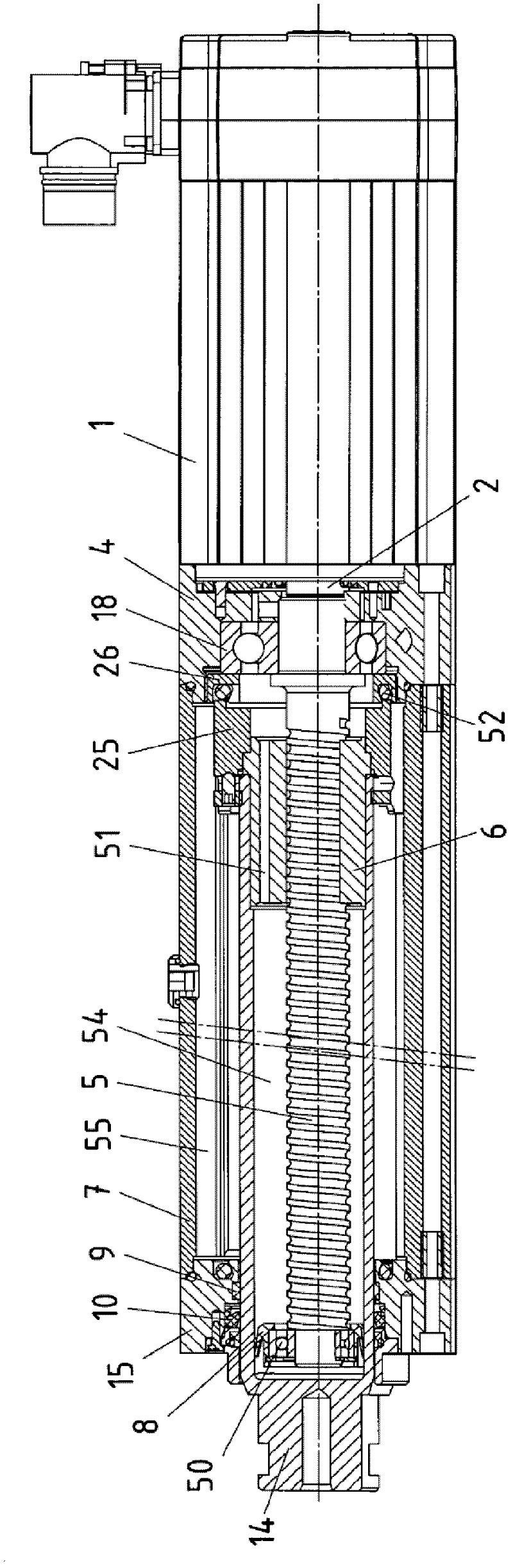

[0077] Now describe the present invention in detail by means of the accompanying drawings:

[0078] The motor housing 1 of the motor, including the rotor shaft 2 and the stator, is tightly connected to the housing parts 4 , 7 , 15 of the spindle motor. Preferably, an O-ring is fitted at each connection interface point of the housing parts, so that tightness is guaranteed even at overpressures above, for example, 2 bar.

[0079] A housing part 4 receives a bearing 18 supporting the threaded screw 5 . The threaded screw is connected to the rotor shaft 2 through a coupling device that can be inserted in the axial direction. The coupling device has claws, between which a plastic material can be arranged. Preferably, this coupling is play-free.

[0080] A seal arranged in the housing part 4 seals the interior of the spindle from the electric motor. In particular, the sealing device 52 is designed as an O-ring.

[0081] The inner space can thus be filled with oil. On the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com