High-speed response electromagnetic valve type fuel injector for motorcycle

A solenoid valve, motorcycle technology, used in machines/engines, fuel injection devices, engine components, etc., can solve the problems of high-speed engine matching, insufficient response time, etc., to achieve high power and torque, fast response speed, Improve the effect of suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

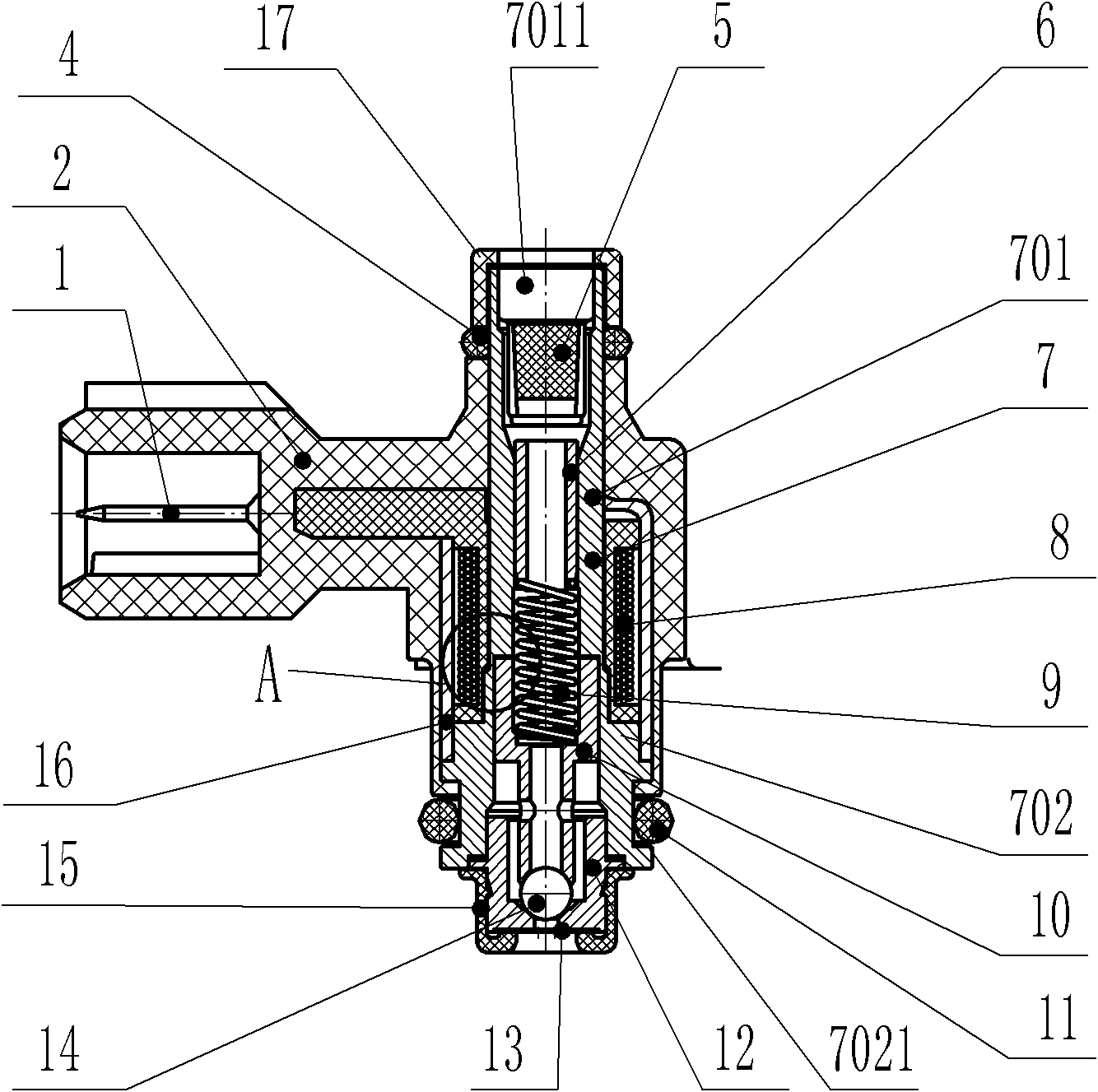

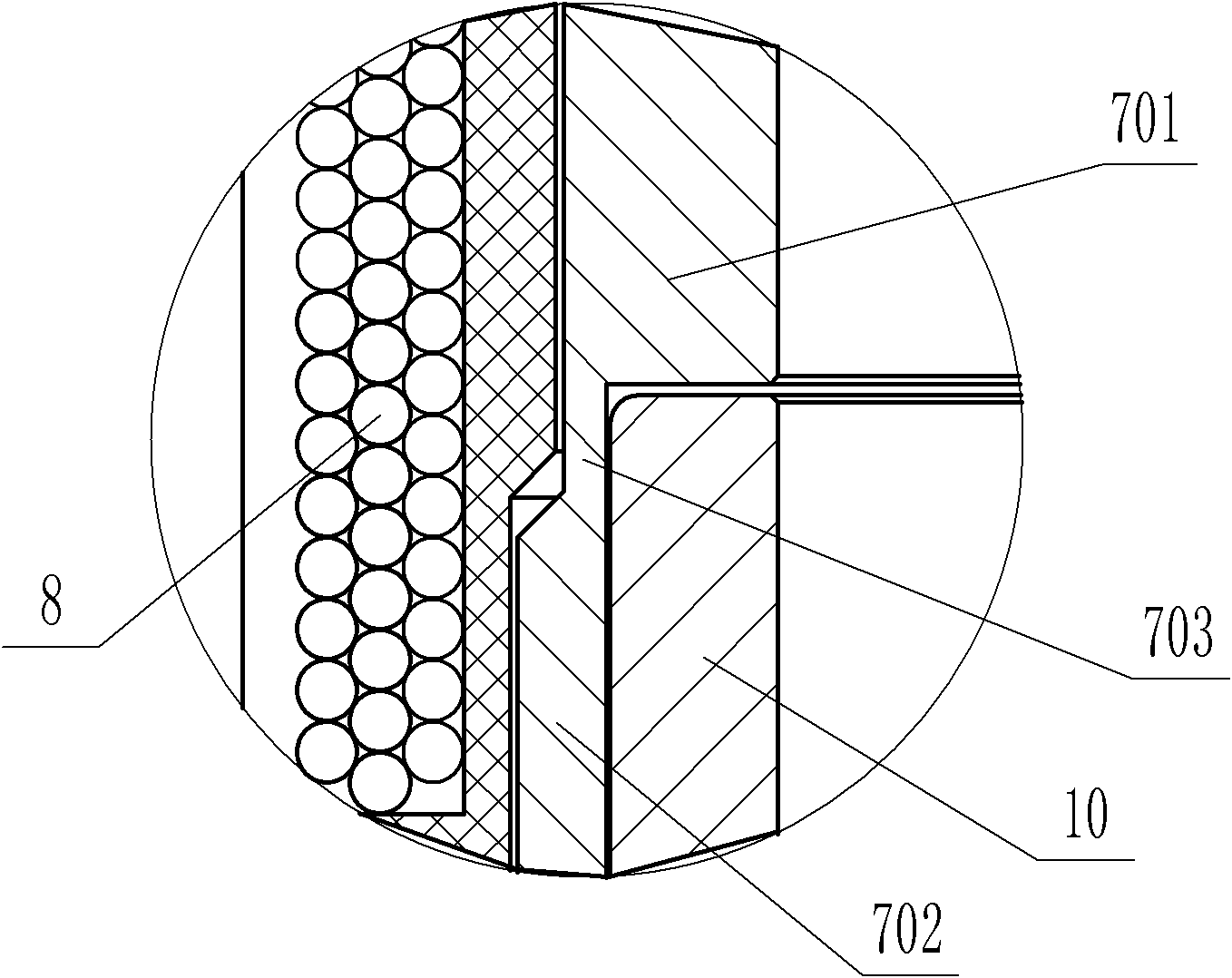

[0036] figure 1 Disclosed in is a motorcycle high-speed response electromagnetic valve fuel injector, which consists of an electrode 1, a housing 2, an oil cap, an oil seal ring 4, a filter screen 5, a limit tube 6, a main shaft 7, an electromagnetic coil 8, The return spring 9, the valve core 10, the air seal ring 11, the valve seat 12, the oil injection orifice 13, the sealing steel ball 14, the protective sleeve 15 and the magnetic conduction sleeve 16 are composed of the electrode 1, the main shaft 7, the electromagnetic coil 8, The magnetic sleeve 16 forms the electromagnetic circuit assembly that generates electromagnetic force; the valve core 10, the valve seat 12, and the sealing steel ball 14 form the valve assembly that generates the action of opening and closing the valve and realizes the sealing function under the action of electromagnetic force; the limit tube 6, The return spring 9 and the oil injection orifice 13 form a flow adjustment assembly that adjusts and...

Embodiment 2

[0039] Embodiment two (best embodiment):

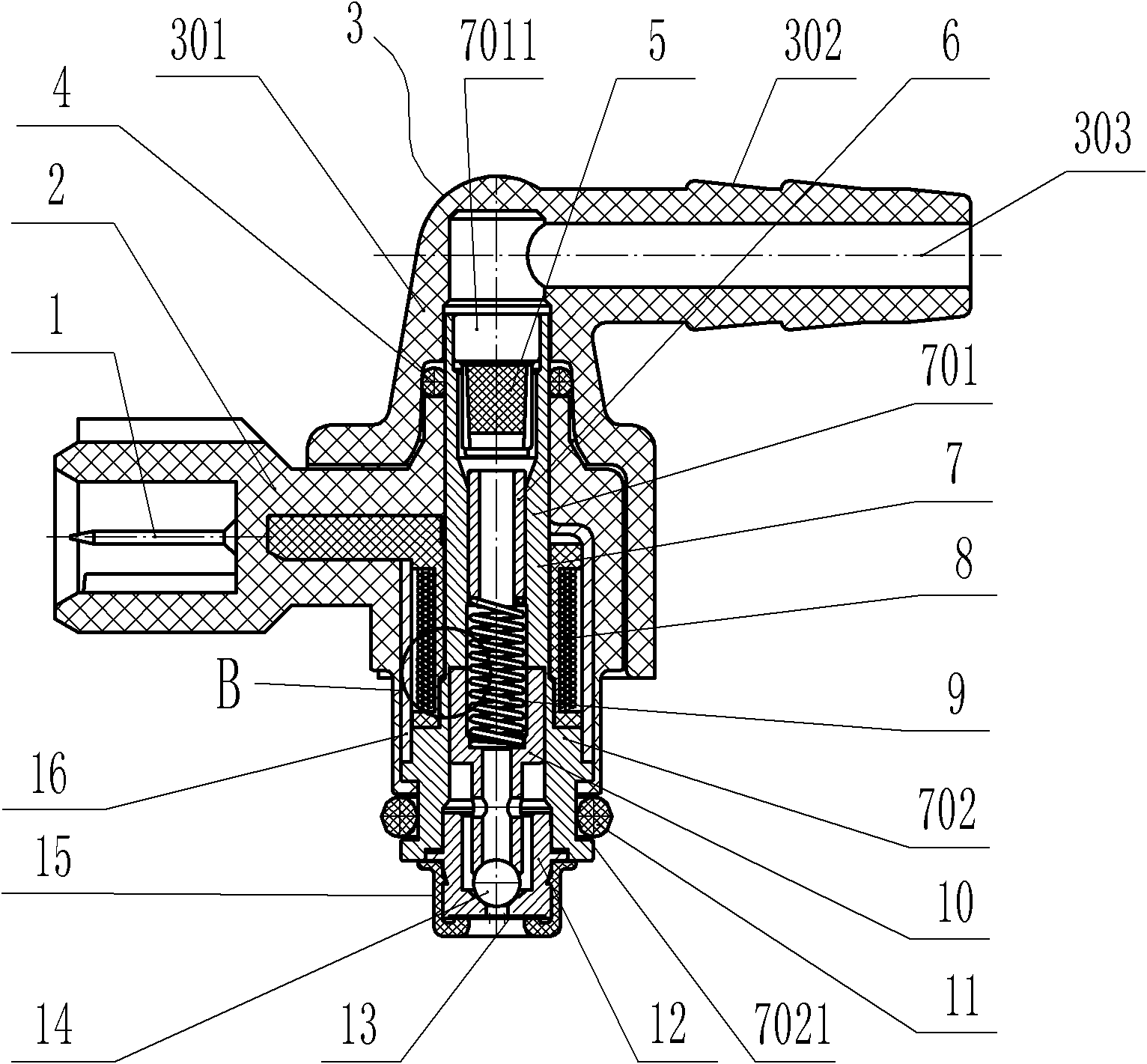

[0040] Figure 3 ~ Figure 7 Disclosed in is another high-speed response solenoid valve fuel injector for motorcycles, its basic structure is the same as that of Embodiment 1, the difference is that the oil cap is a rotary oil cap 3 that can be rotated by 180°, The rotary oil cap 3 is an inverted 7-shaped structure composed of an oil cap body 301 and an oil inlet nozzle 302 integrated with the top of the oil cap body. The oil cap body 301 is installed on the spindle oil inlet 7011 and outside the housing 2 , and the oil cap body 301 and the oil inlet nozzle 302 are provided with an oil inlet passage 303 connected with the main shaft oil inlet 7011; the shell is provided with a surface that is matched with the oil cap body so that the rotating oil cap can be used for 180 ° rotation limit protrusion; the housing 2 is also provided with a mounting boss 201 on one side, and a mounting hole 2011 is opened longitudinally in the mounting bos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com