Process for producing artificial stone with decorative pattern

A production process, artificial stone technology, applied in the direction of manufacturing tools, clay mixing devices, clay preparation devices, etc., to achieve the effect of overcoming simple patterns, high degree of automation, and natural and smooth texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

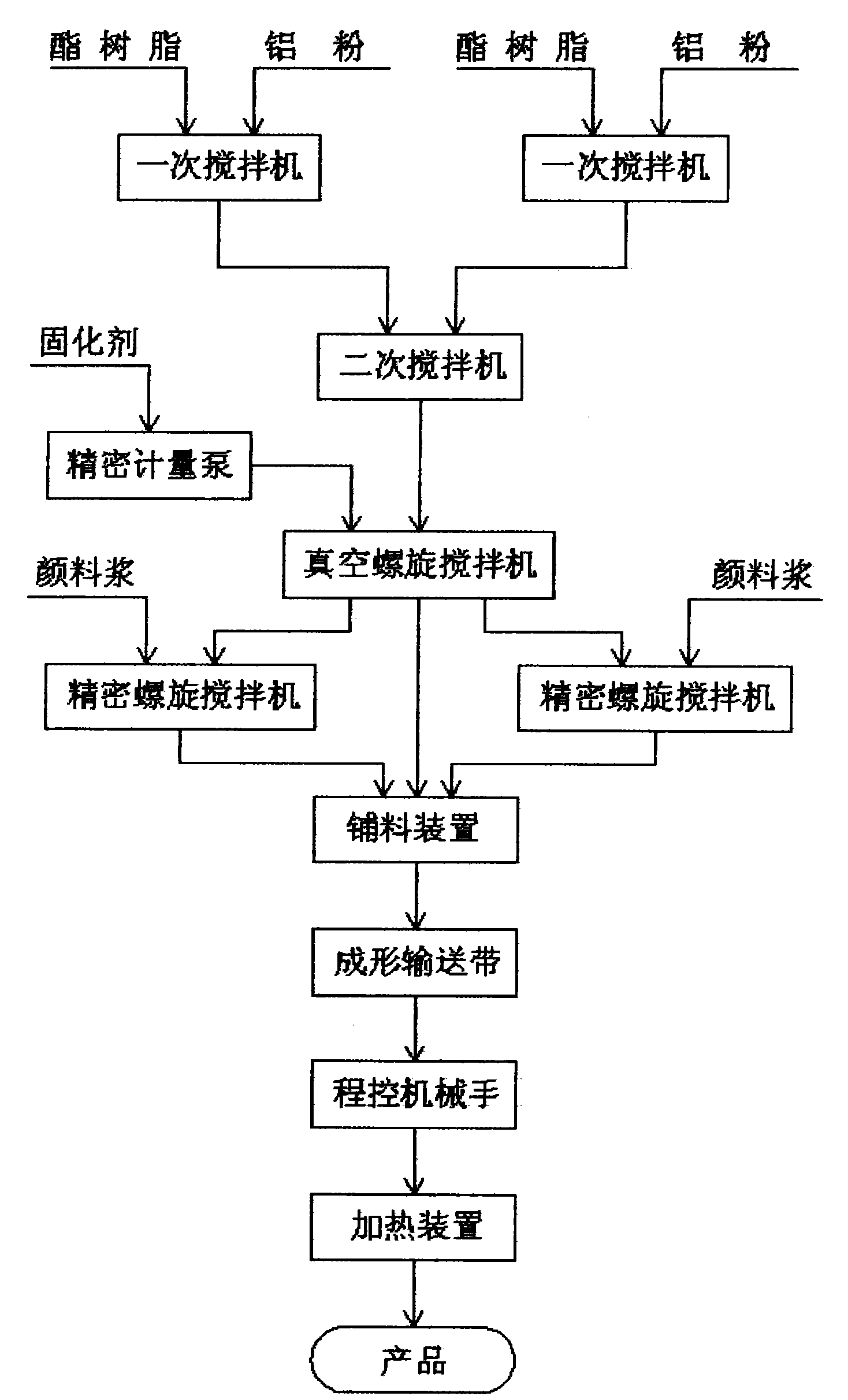

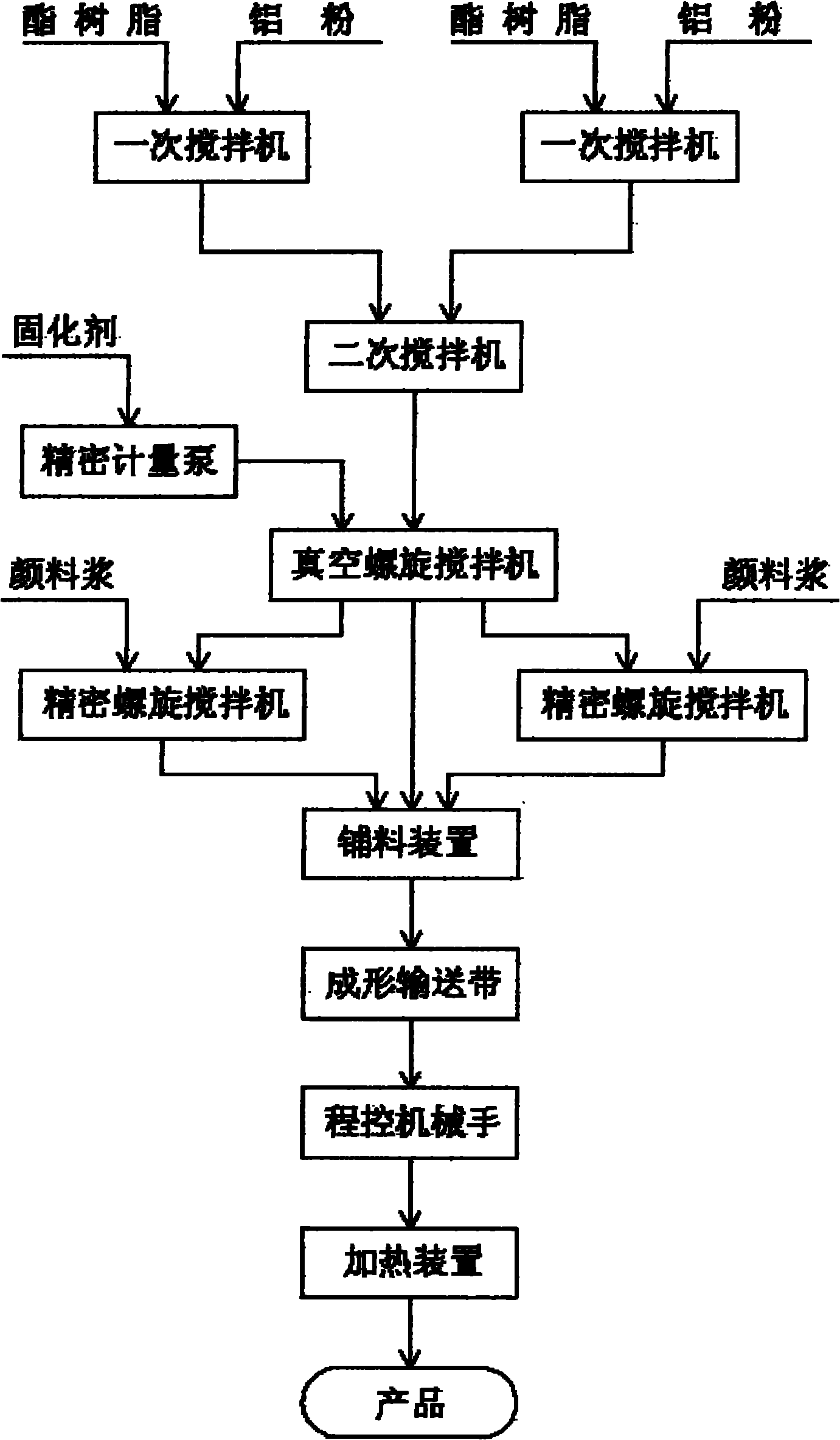

[0018] Embodiment 1: as figure 1 As shown, a pattern artificial stone production process, it includes the following steps: (1) preparation of premix: including two ordinary stirring and a vacuum stirring, the two ordinary stirring is the unsaturated polyester Resin and aluminum hydroxide powder are added to the primary mixer and stirred, and then added to the secondary mixer for stirring, wherein there are two primary mixers, which feed the secondary mixer in turn; the vacuum stirring is used to stir the secondary mixer evenly The raw material slurry and curing agent are all injected into the vacuum screw mixer for stirring; (2) Preparation of color material: take a small part of the artificial stone premix that has been vacuum stirred and mix it with two kinds of pigments through a precision screw mixer to prepare two kinds of pigments. Artificial stone color. (3) Spreading material: Layer the prepared premix and color material evenly on the forming conveyor belt, the bottom...

Embodiment 2

[0019] Embodiment 2: other processing steps are identical with embodiment 1, and difference is: (3) spread material: will prepare premix and color material through insufficient mixing cloth and enter on the forming conveyer belt, through sedimentation and dispersion A layer of artificial stone slurry of uniform thickness is formed on the forming conveyor belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com