Process and device for treating tail gas during producing trichlorosilane

A trichlorosilane, treatment process technology, applied in chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, steam condensation, etc., can solve environmental pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

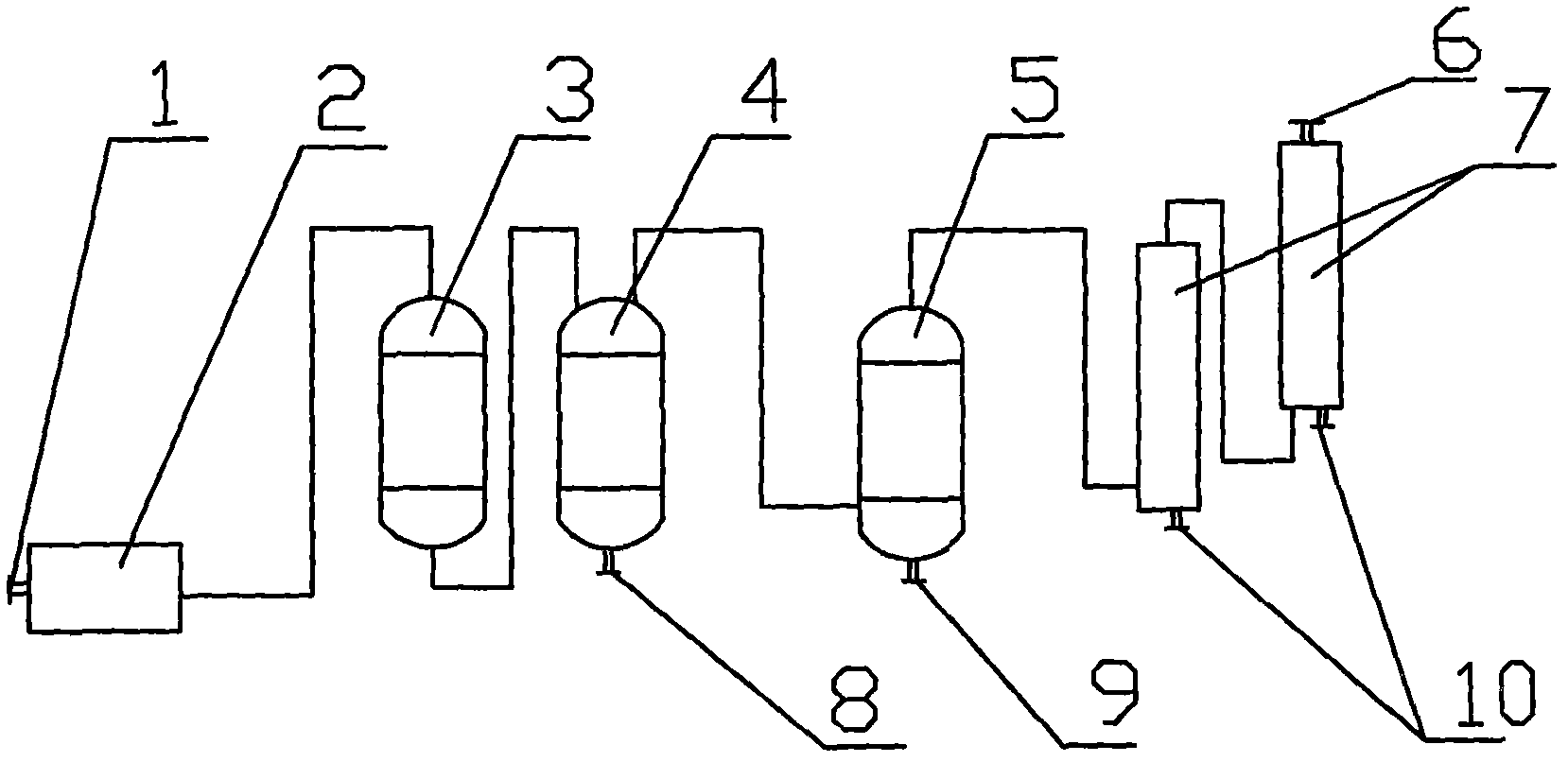

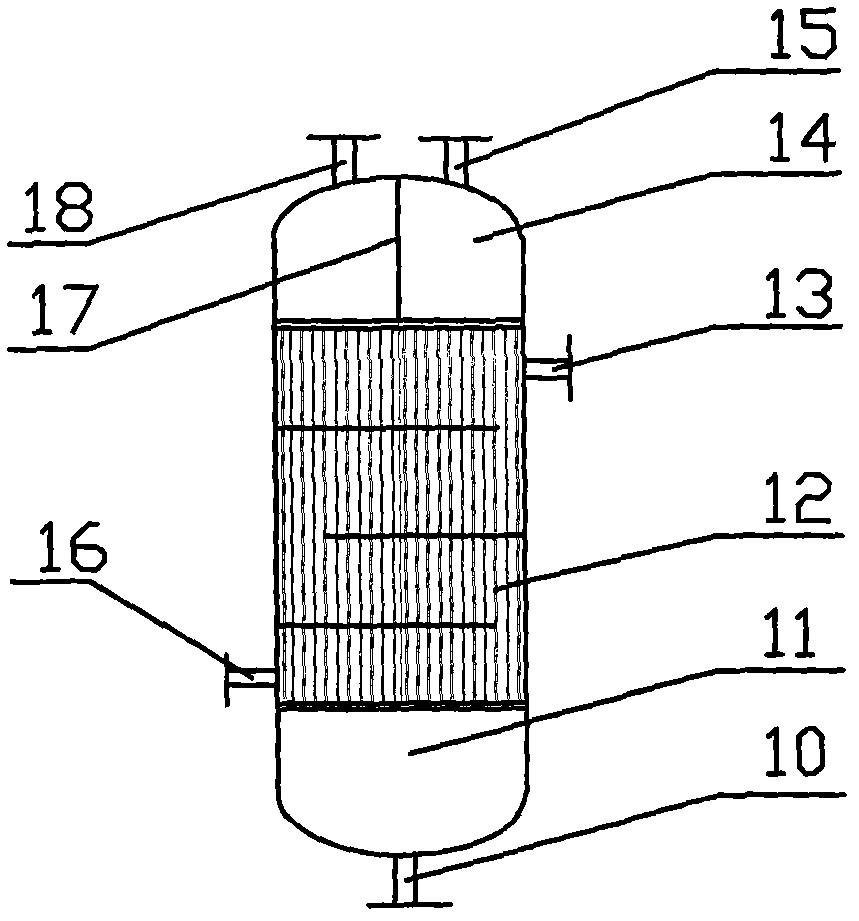

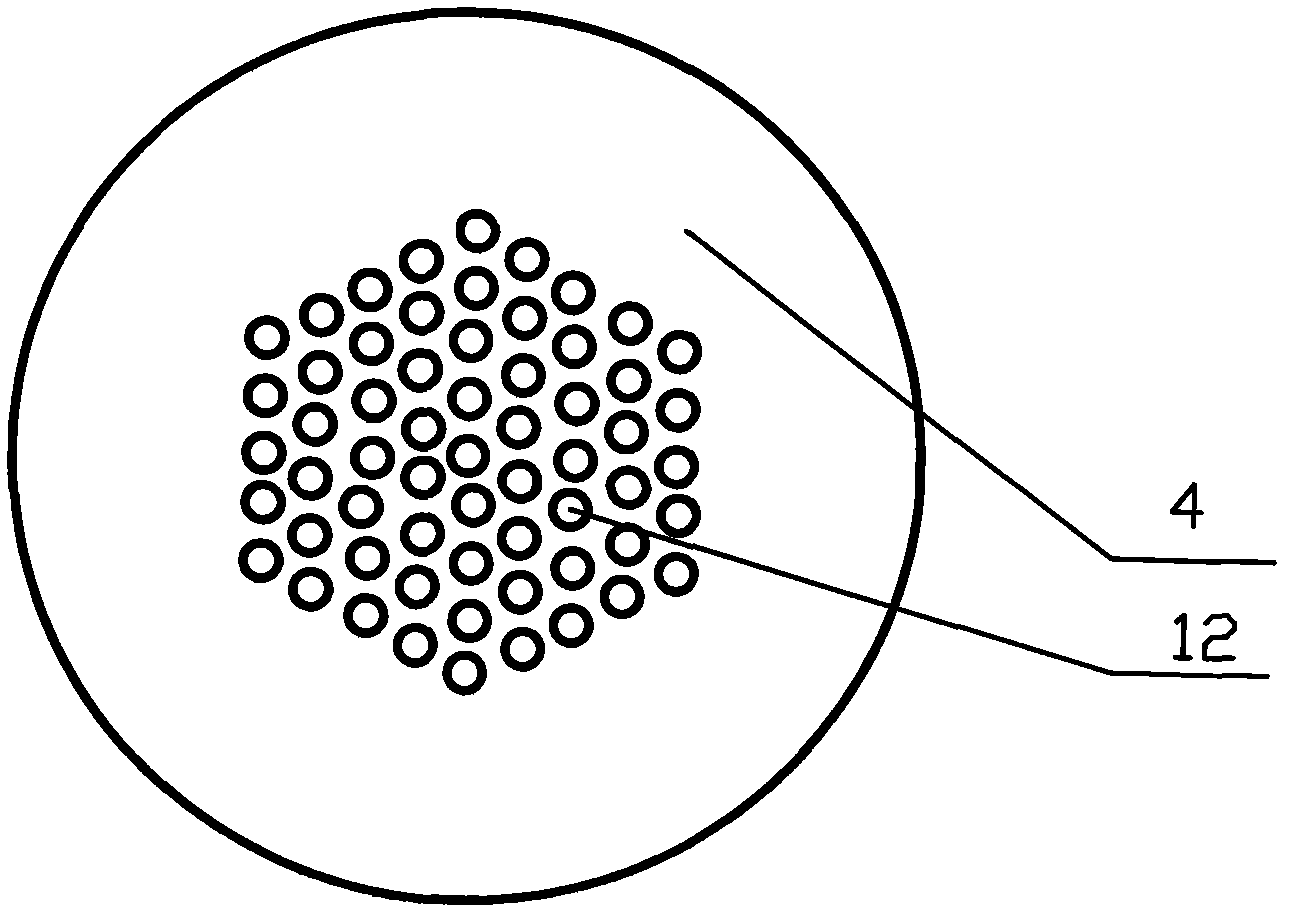

[0019] The treatment process of the present invention is that after the tail gas of the trichlorosilane synthesis section and the trichlorosilane fractionation section is pressurized and compressed by a diaphragm compressor, the pressure of the diaphragm compressor is 0.5-0.8Mpa. Condensate through the water-cooled condenser after the machine in turn, deep condense in the deep-cooled condenser after the machine, absorb in the circulating absorption tower, and recover chlorosilane. The tail gas absorbed by the circulating absorption tower passes through the two-stage falling film absorption tower to recover the hydrogen chloride in the tail gas to make 30% hydrochloric acid. The tail gas absorbed by the falling film absorption tower is basically hydrogen, with only a small amount of nitrogen, which can be directly vented.

[0020] The condensation temperature of the circulating absorption tower is -25°C, -24°C, -23°C, -21°C or -20°C. Pressure: 0.5 ~ 0.55Mpa.

[0021] The gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com