Chip scale integration packaging process and light emitting diode (LED) device

An LED device and integrated packaging technology, which is applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of reducing the light efficiency of the device, uneven light color, etc., achieve low production costs, reduce light energy loss, and increase luminescence The effect of light color uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

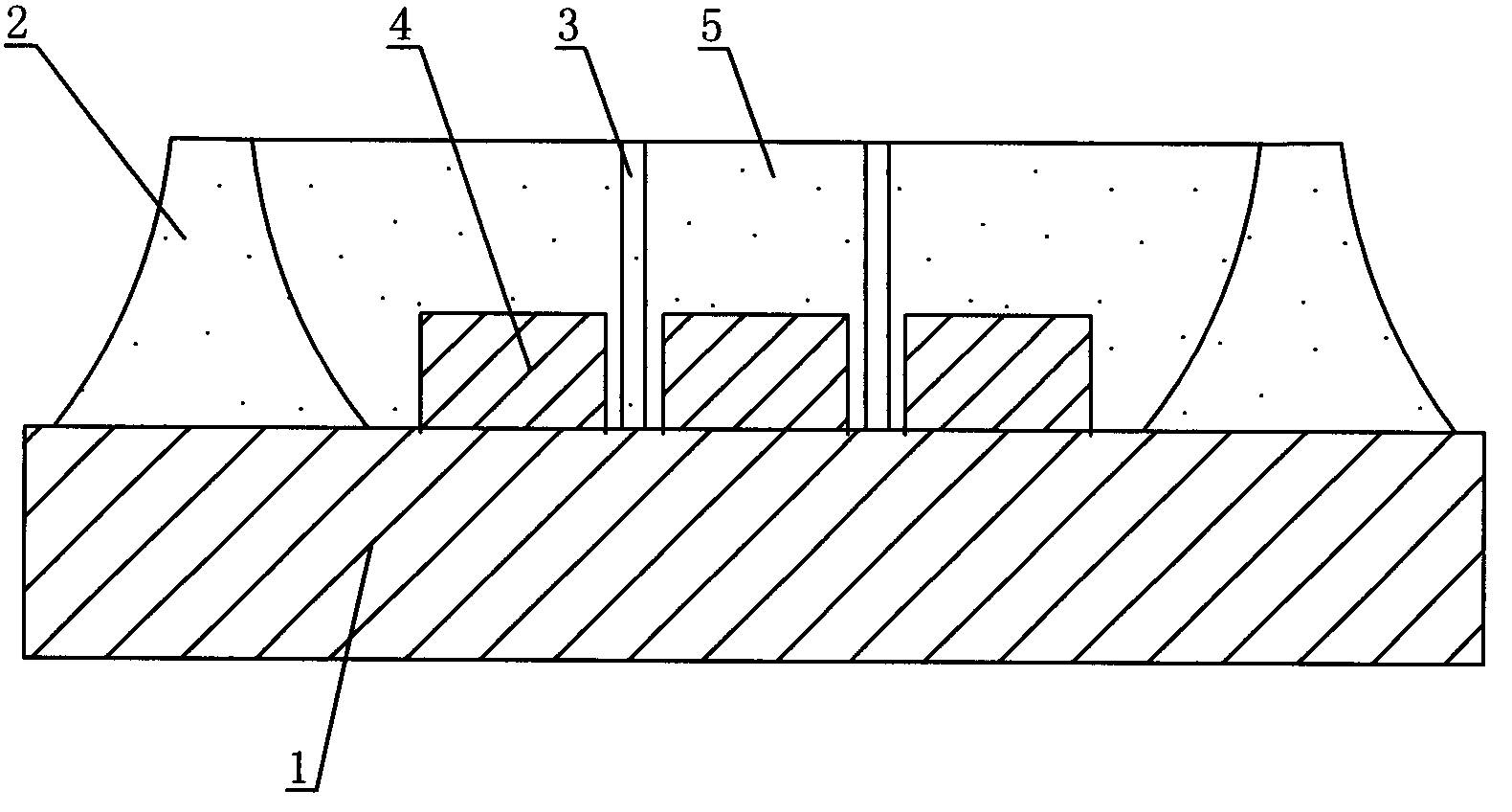

[0038] Such as figure 1 with figure 2 The LED device shown includes a flat panel support 1, which is circular, and the flat panel support 1 is divided into an intermediate area 5 and two or more peripheral areas 6 other than the intermediate area. The intermediate area 5 is Circular, the peripheral area 6 is fan-shaped, and the peripheral area 6 is equally distributed with the center of the intermediate area as the center of the circle. In this embodiment, there are eight peripheral areas 6; LED chips 4 are fixed in the intermediate area 5 and the peripheral area 6, Each area includes more than one LED chip. In this embodiment, one LED chip 4 is installed in each area, wherein the LED chip in the middle area 5 emits red light, and the LED chip in the peripheral area 6 is a blue series; A phosphor glue dam 2 is provided on the flat plate support outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com