Silicon-based long-wave infrared waveguide and preparation method thereof

A technology of infrared light wave and long wave, applied in the direction of optical waveguide light guide, light guide, optics, etc., can solve the problems of difficult preparation, high equipment requirements, and great difficulty, and achieve good prospects and value, low process difficulty, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

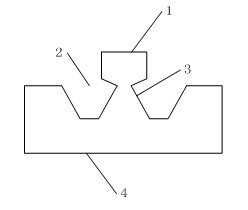

[0062] Taking the wavelength of 10.6um and needing to etch 30um as an example, the side etching length can be obtained by the tangent formula, , by calculating the ratio of the width of the waveguide to the width of the support platform is greater than 2.5, in this example, the width of the waveguide is 5um, the width of the support platform is less than 2um, so the length of the mask is .

[0063] In the process of hollowing out the silicon substrate on the lower end surface of the waveguide, the lower end surface of the waveguide will be eroded to a certain extent due to the erosion effect, and the erosion will stop when it reaches the oxide layer on the side wall of the waveguide. The angle between the erosion surface and the horizontal plane is also 54.7 degrees, so the erosion depth in the vertical direction can be calculated by the tangent formula. In this example, the distance to be hollowed out on one side of the waveguide is 1.5um, so the depth of erosion inside th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com