LED automotive dipped headlight

An LED light source and low beam technology, applied in the field of LED lighting, can solve the problems of less application of headlights and stay, and achieve the effects of saving lamp space, stable and output luminous flux, and prolonging lamp life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

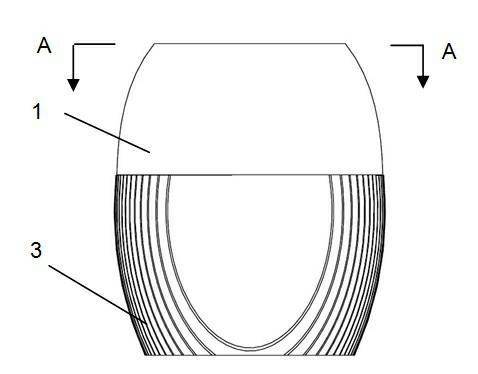

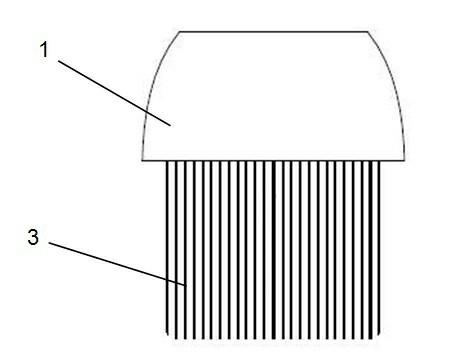

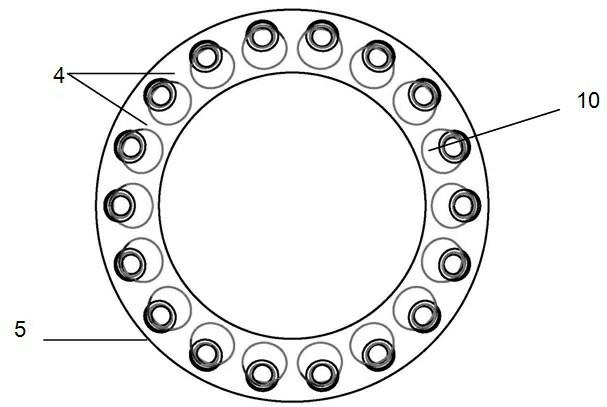

[0019] An embodiment, an LED car low beam, consists of 18 high-power LED light sources 9, an independent reflector 10 for each LED, a concave lens 2 and an oval heat sink. Each reflective cup 10 and an LED light source 9 form a small reflective optical system. The reflective cup 10 adopts a parabolic curved surface, and the LED light source 9 is located at one of the focal points of the parabolic curved surface. The light emitted by each LED light source is directly irradiated within Φ30°, and when the angle is greater than Φ30°, the light is reflected by the reflector 10 to emit light in a manner close to parallel light. All the reflectors are arranged in a ring, and are inclined at a specific angle α to the inner side of the lamp to ensure that the parallel light reflected by the reflector 10 is projected toward the front focus 7 of the concave lens 2, and is refracted by the concave lens 2 to irradiate forward with a parallel beam. This mixed light distribution method of re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com