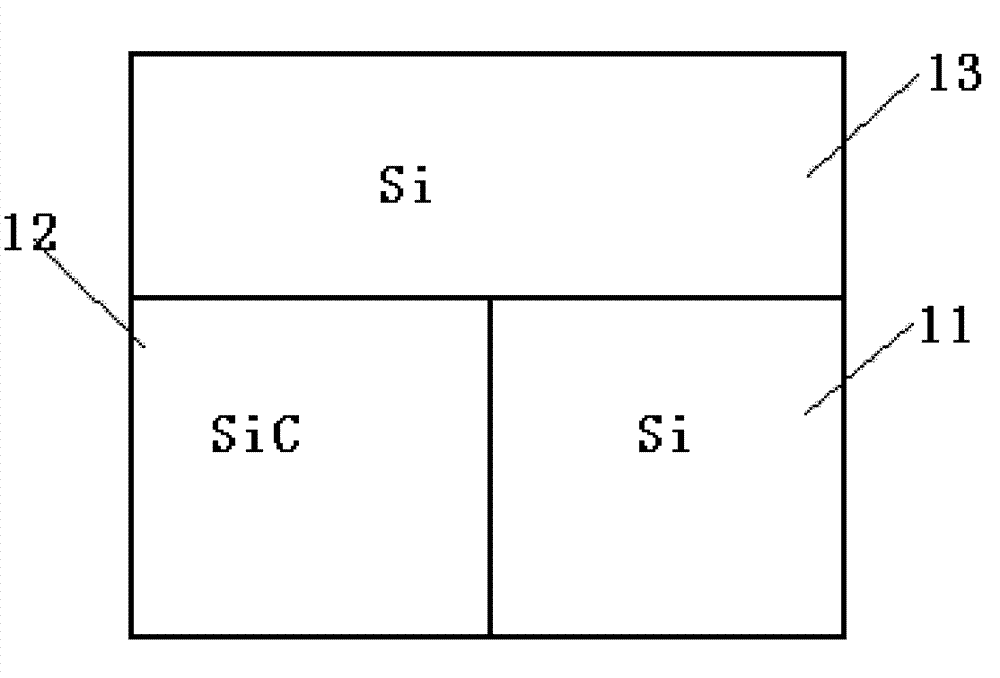

RB-SiC base reflector surface modified layer structure and preparation method thereof

A technology of surface modification layer and substrate surface, applied in coating, sputtering coating, metal material coating process, etc. Problems such as poor polishing characteristics of the sexual layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

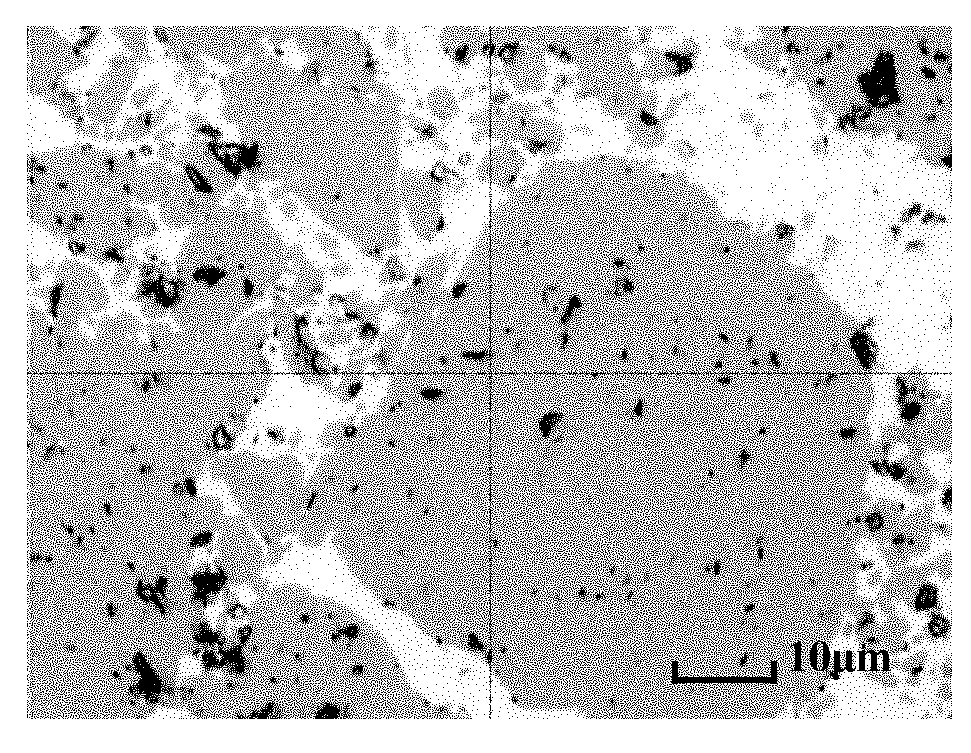

Embodiment 1

[0029] The preparation method of the RB-SiC base reflector structure of the present invention comprises the following specific steps:

[0030] 1. Preparation of coating conditions: fix the RB-SiC substrate on the workpiece fixture of the coating machine, and put Si grains in the crucible; vacuumize the vacuum chamber of the coating machine to 1.0×10 -3 Pa; bake in the temperature range of 200°C and keep the temperature constant for 30 minutes; then use the Kaufman ion source placed in the coating machine to fill the substrate with Ar gas for 20 minutes of ion cleaning, and the Ar gas volume flow rate is 25 sccm;

[0031] 2. Si phase composition on the surface of carbonized RB-SiC substrate: adjust the Kaufman ion source to reduce the volume flow rate of Ar gas to 8 sccm, and at the same time reduce the CH 4 Gas feed, CH 4 The gas volume flow rate is 15 sccm; adjust the Kaufman ion source so that the plate voltage reaches 600V, the beam current reaches 150mA, and the CH 4 Ion...

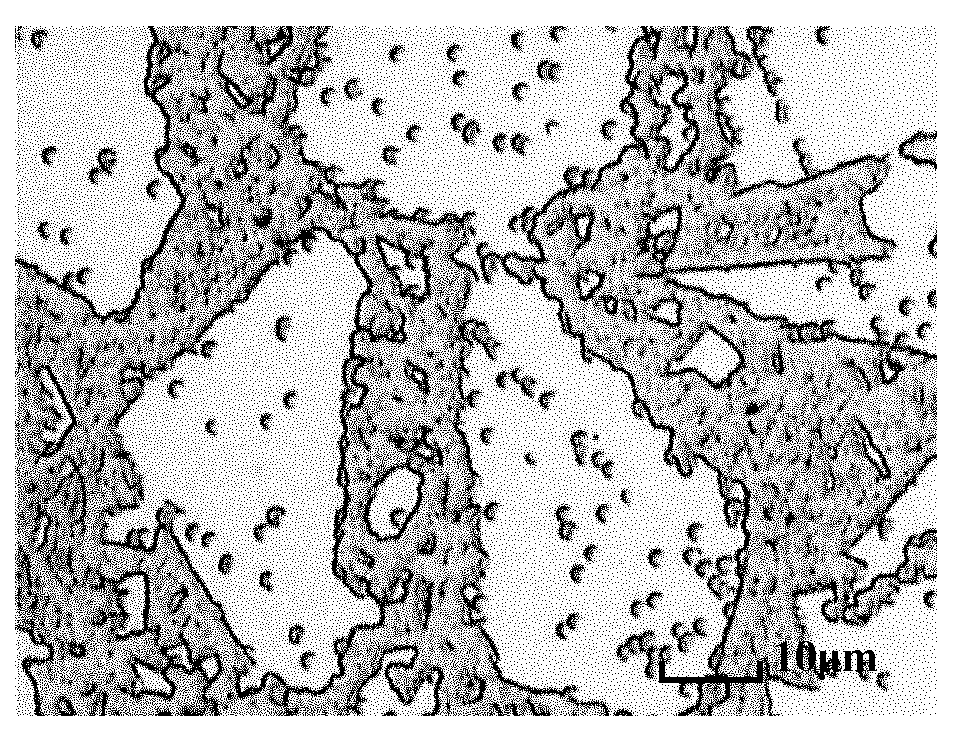

Embodiment 2

[0036] The preparation method of the RB-SiC base mirror structure of the present invention comprises the following specific steps:

[0037] 1. Preparation of coating conditions: fix the RB-SiC substrate on the workpiece fixture of the coating machine, and put Si grains in the crucible; vacuumize the vacuum chamber of the coating machine to 1.5×10 -3 Pa; bake in the temperature range of 200°C and keep the temperature constant for 50 minutes; then use the Kaufman ion source placed in the coating machine to fill the substrate with Ar gas for 40 minutes of ion cleaning, and the Ar gas volume flow rate is 25 sccm;

[0038] 2. Si phase composition on the surface of carbonized RB-SiC substrate: adjust the Kaufman ion source to reduce the volume flow rate of Ar gas to 11 sccm, and at the same time reduce the CH 4 Gas feed, CH 4 The gas volume flow rate is 15 sccm; adjust the Kaufman ion source so that the plate voltage reaches 700V, the beam current reaches 150mA, and the CH 4 Ioniz...

Embodiment 3

[0043] The preparation method of the RB-SiC base mirror structure of the present invention comprises the following specific steps:

[0044] 1. Preparation of coating conditions: fix the RB-SiC substrate on the workpiece fixture of the coating machine, and put Si grains in the crucible; vacuumize the vacuum chamber of the coating machine to 1.5×10 -3 Pa; bake in the temperature range of 300°C and keep the temperature constant for 40 minutes; then use the Kaufman ion source placed in the coating machine to fill the substrate with Ar gas for 30 minutes of ion cleaning, and the Ar gas volume flow rate is 30 sccm;

[0045] 2. Si phase composition on the surface of carbonized RB-SiC substrate: adjust the Kaufman ion source to reduce the volume flow rate of Ar gas to 10 sccm, and at the same time reduce the CH 4 Gas feed, CH 4 The gas volume flow rate is 20sccm; the Kaufman ion source is adjusted to make the plate voltage reach 700V, the beam current reaches 160mA, and the CH 4 Ion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com