Method for preparing TiWN/MoS2 composite film

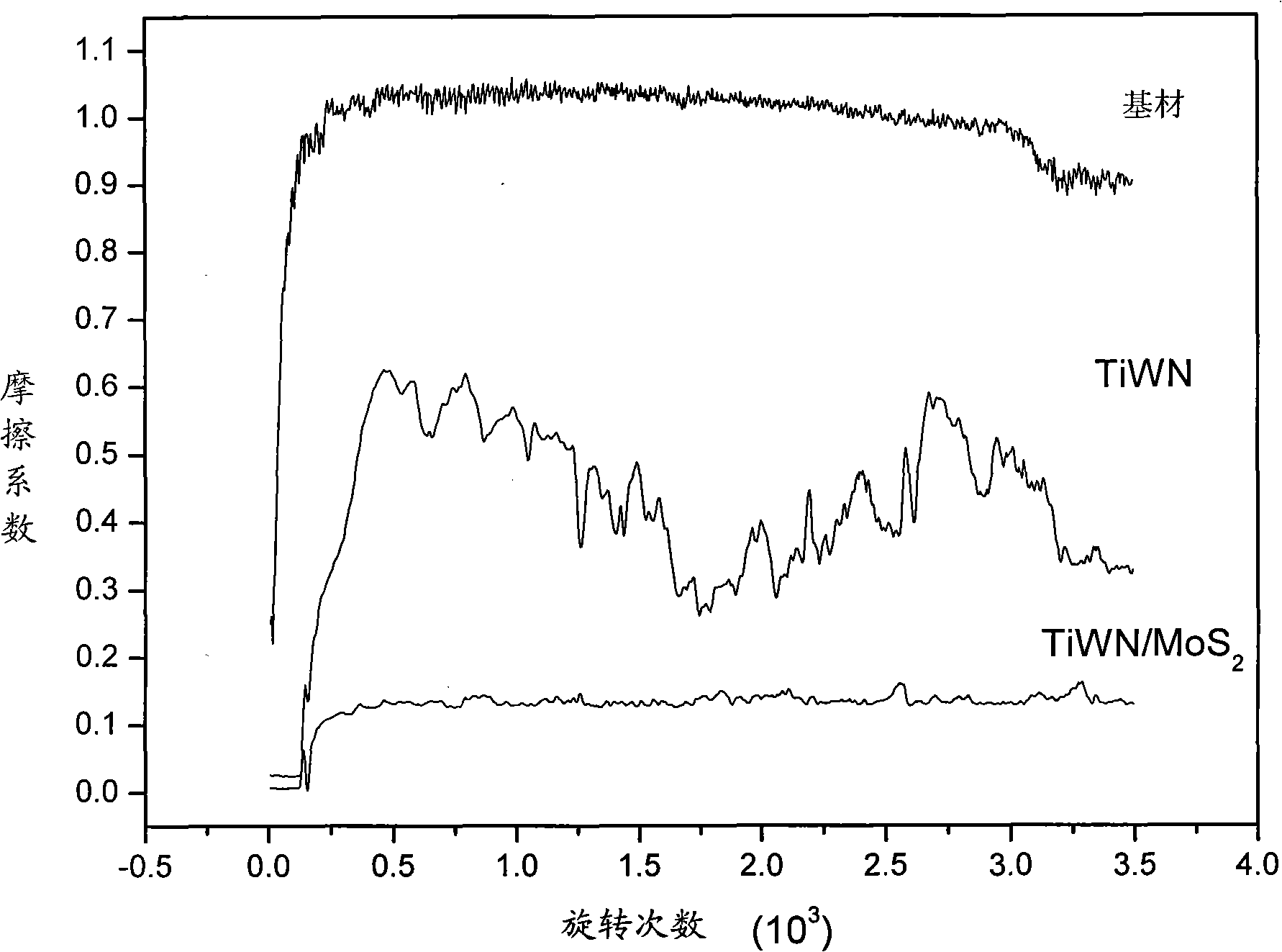

A composite thin film and thin film technology, which is applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems that the film cannot reach the service life, high friction coefficient, etc., so as to reduce the contact area and shear strength, Effect of lower friction coefficient and higher productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Prepare TiWN / MoS as follows 2 Composite film:

[0021] (1) Pretreatment: first, the surface of Cr40 steel is polished, then cleaned and dried with acetone, alcohol and deionized water successively to obtain the base material;

[0022] (2) Preparation of TiWN film: in a mixed protective atmosphere with a volume ratio of nitrogen and argon of 3:1, using Ti target and W target by magnetron sputtering method, with 200W power to carry out reactive sputtering on the surface of the above substrate Shot to generate TiWN thin film;

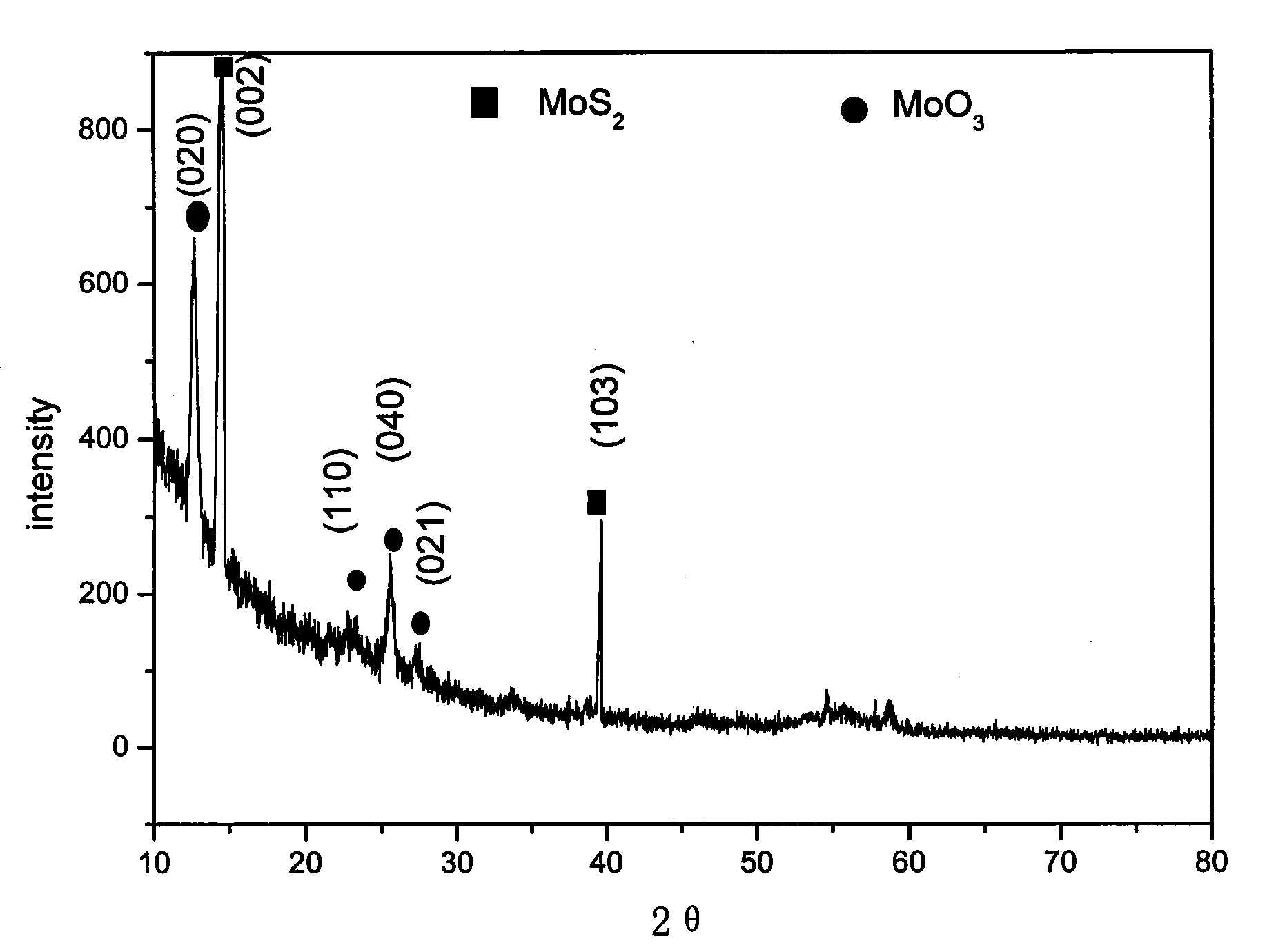

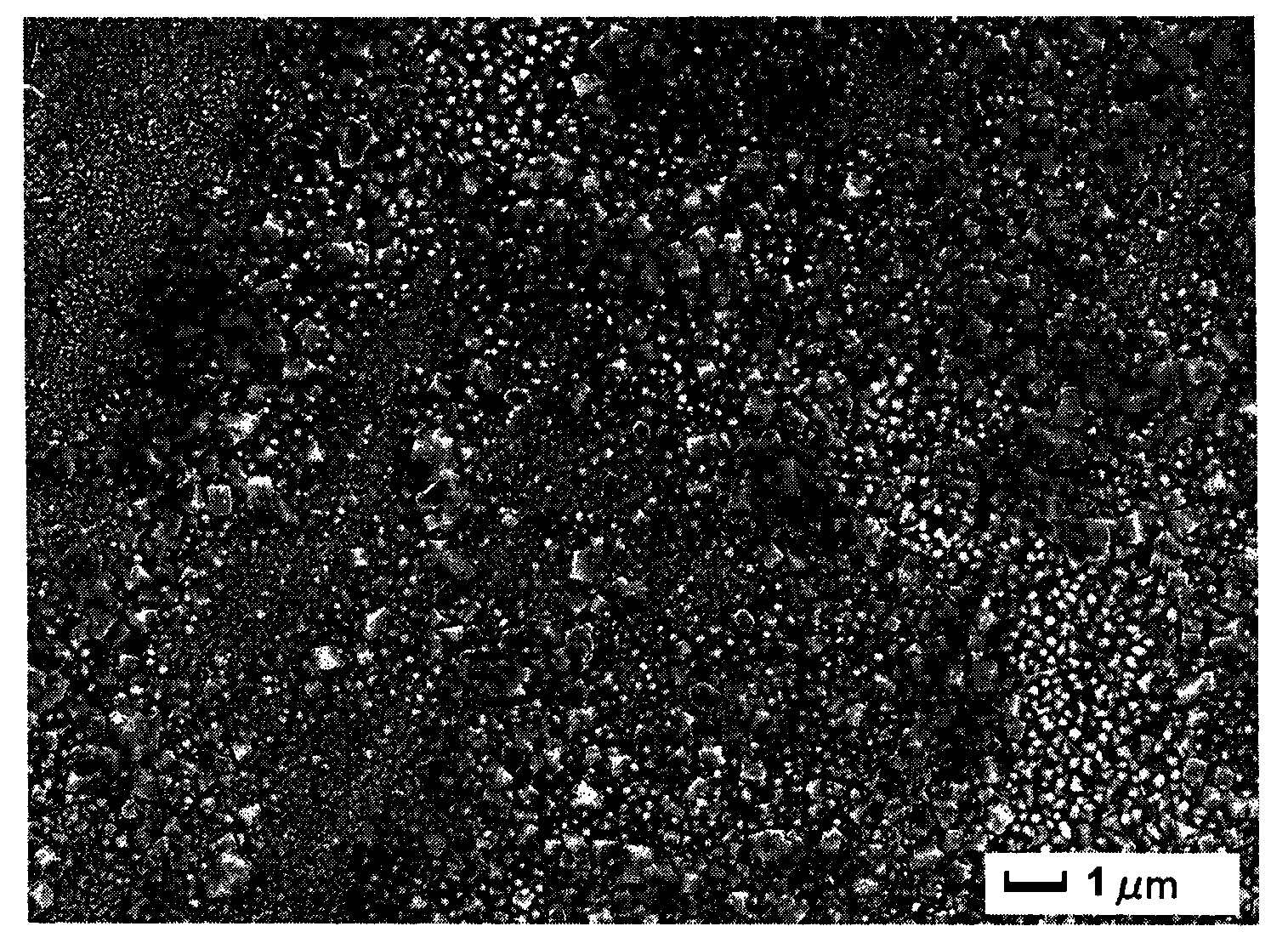

[0023] (3) Preparation of MoS 2 Thin film: in argon atmosphere, using MoS 2 The target was sputtered MoS on the above TiWN film by magnetron sputtering method with a power of 150W 2 thin film, prepared TiWN / MoS 2 Composite film.

Embodiment 2

[0025] Prepare TiWN / MoS as follows 2 Composite film:

[0026] (1) Pretreatment: first, the surface of Cr40 steel is polished, then cleaned and dried with acetone, alcohol and deionized water successively to obtain the base material;

[0027] (2) Preparation of TiWN thin film: in a mixed protective atmosphere with a volume ratio of nitrogen and argon of 2:1, using Ti target and W target by magnetron sputtering method, with a power of 250W, react sputtering on the surface of the above substrate Shot to generate TiWN thin film;

[0028] (3) Preparation of MoS 2 Thin film: in argon atmosphere, using MoS 2 The target was sputtered MoS on the above TiWN film by magnetron sputtering method with a power of 150W 2 thin film, prepared TiWN / MoS 2 Composite film.

[0029] Practice has proved that the TiWN / MoS of the present invention 2 The preparation method of the composite film has the characteristics of cheap and easy-to-obtain raw materials, simple process, safety and environme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com