Environment-friendly epoxy molding compound and preparation method thereof

An epoxy molding compound, an environment-friendly technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems affecting the electrical performance, heat resistance and reliability of products, and achieve low production cost, convenient processing, and high production efficiency. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

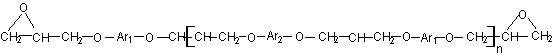

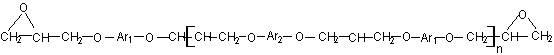

Method used

Image

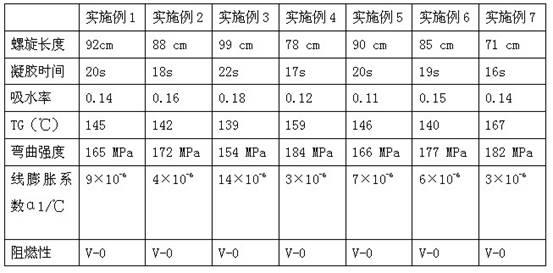

Examples

Synthetic example A

[0047] Add 50g of HP7200 (dicyclopentadiene epoxy resin, Japan Dai Ink Co.), 100g of ODOPB (phosphorous compound, Jiangsu Huihong) to a four-necked flask equipped with an electric stirrer, reflux condenser, thermocouple, and nitrogen inlet Jinpu Chemical Co., Ltd.), add 0.1g accelerator, react at 150 degrees for 6 hours to obtain dicyclopentadiene-type phosphorus-containing epoxy resin with a phosphorus content of 4.2%.

Synthetic example B

[0049]The synthesis procedure is the same as that of Synthesis Example A, except that 100g of HP7200 (dicyclopentadiene epoxy resin, Japan Dai Ink Co.), 100g of ODOPB (phosphorous compound, Jiangsu Huihong Jinpu Chemical Co., Ltd.) is added, and 0.15g of accelerator is added. , to obtain a phosphorus content of 3.6% dicyclopentadiene-type phosphorus-containing epoxy resin.

Synthetic example C

[0051] The synthesis procedure is the same as that of Synthesis Example A, except that 100g of HP7200 (dicyclopentadiene epoxy resin, Japan Dai Ink Co.), 50g of ODOPB (phosphorous compound, Jiangsu Huihong Jinpu Chemical Co., Ltd.) and 0.1g of accelerator are added. , to obtain a phosphorus content of 3.1% dicyclopentadiene-type phosphorus-containing epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com