Formula and preparation method of light, energy-saving, heat-proof, sound-proof and fireproof door panel

A technology for thermal insulation, sound insulation and fire prevention, which is applied in chemical instruments and methods, manufacturing tools, ceramic products, etc., can solve the problems of semi-finished boards, etc., and achieve good flatness, cost saving, and high thickness uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

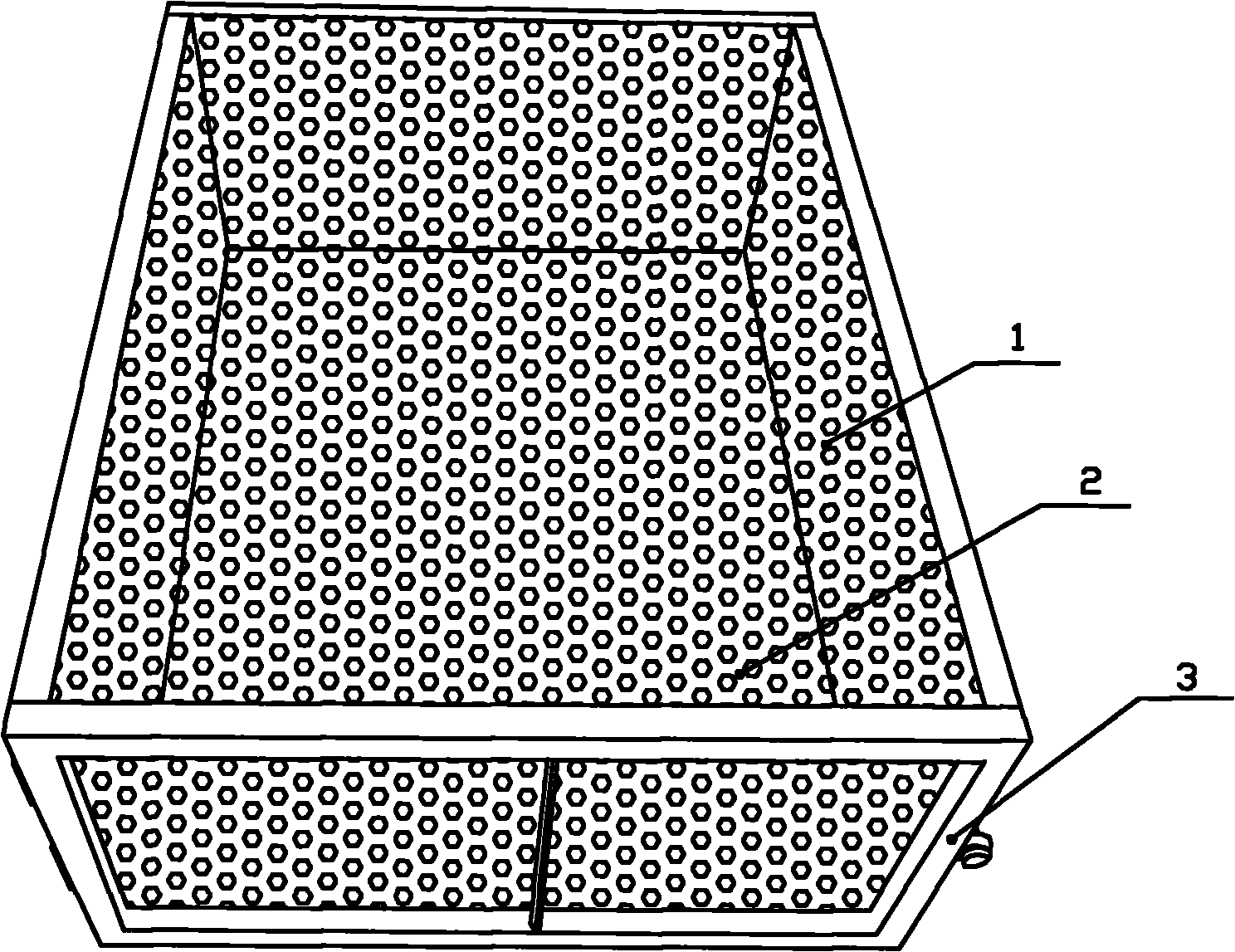

Image

Examples

Embodiment 1

[0036] Weigh the raw material (kg) according to the following weight:

[0037] Magnesium cement 100, carbon fiber 0.5, glass fiber 0.5, plant fiber 0.5, sodium lauryl sulfate 0.42, emulsifier OP-100.28;

[0038] A method for manufacturing a lightweight, energy-saving, heat-insulating, heat-insulating, sound-insulating, and fireproof door core board includes the following steps:

[0039] (1) 0.42 kilograms of sodium lauryl sulfate and 0.28 kilograms of emulsifier OP-10 are mixed to prepare whipping agent;

[0040] (2) Put the bundled chopped fibers with a length of 1 to 3 cm into the mixer, add one-third of the above-mentioned brine to soften the total weight of the raw materials, that is, about 34 kg of brine, and stir it under the stirring of the stirring paddle Disperse the chopped fibers, add magnesium cement and pre-mixed foaming agent, stir for 7 minutes, 0.5 kg of carbon fiber, 0.5 kg of glass fiber, and 0.5 kg of plant fiber are evenly distributed in 100 kg of magnesiu...

Embodiment 2

[0044] Weigh the raw material (kg) according to the following weight:

[0045] Magnesium cement 90, carbon fiber 0.2, glass fiber 0.2, plant fiber 0.1, sodium lauryl sulfate 0.6, emulsifier OP-10 0.4;

[0046] The preparation method is as in Example 1.

Embodiment 3

[0048] Weigh the raw material (kg) according to the following weight:

[0049] Magnesium cement 110, carbon fiber 1, glass fiber 0.5, plant fiber 0.5, sodium lauryl sulfate 0.3, emulsifier OP-10 0.2;

[0050] The preparation method is as in Example 1.

[0051] Product specifications and sizes of the present invention:

[0052] Length: 800-2400mm

[0053] Width: 600-1200mm

[0054] Thickness: 15-100mm

[0055] Product use of the present invention:

[0056] 1. Lightweight partition walls, lightweight fireproof partitions, heat and sound insulation walls, and partitions;

[0057] 2. Thermal insulation materials;

[0058] 3. Fire door core filling material.

[0059] Because the magnesium cement product is an exothermic chemical reaction when it is solidified, its heat release rate is high, and the temperature can reach 110-125°C (related to the ambient temperature during molding); at the same time, its exothermic reaction time is relatively concentrated (about 20 minutes aro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com