Regular graphene and preparation method thereof

A graphene and regular technology, applied in the field of regular graphene and its preparation, to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The first step, the preparation of catalyst:

[0027] The substrate is ultrasonically cleaned with deionized water, ethanol, and acetone in sequence, and then oven-dried, and then processed by chemical vapor deposition, physical vapor deposition, vacuum thermal evaporation, magnetron sputtering, plasma-enhanced chemical vapor deposition, electrochemical method or Deposition techniques such as printing deposit a layer of metal on the substrate surface, or directly use commercial metal foils (such as gold, silver, copper, iron, cobalt, nickel, etc.) as catalysts.

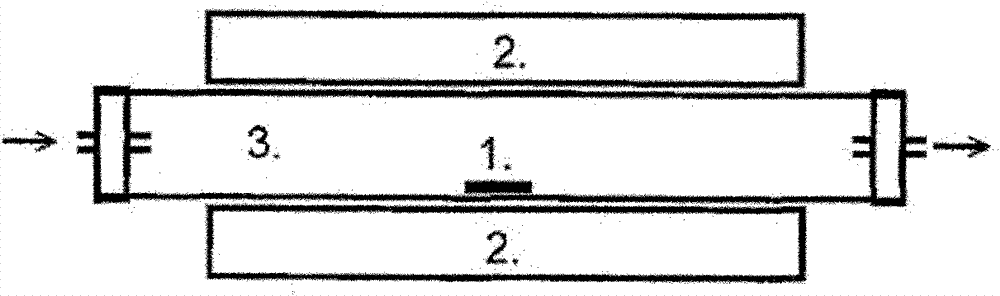

[0028] The second step, the vapor deposition device such as figure 1 As shown, the substrate or metal foil deposited with metal is placed in the middle of a clean quartz tube, and the quartz tube is placed in the electric furnace so that the middle of the quartz tube is exactly in the central area of the electric furnace. First use a mechanical pump to pump out the air and moisture in the quartz tube, then p...

Embodiment 1

[0033] Embodiment 1, preparation regular graphene

[0034] In the first step, a 25um thick copper foil (purity 99.8%) is ultrasonically cleaned with deionized water, ethanol and acetone, and then dried in an oven.

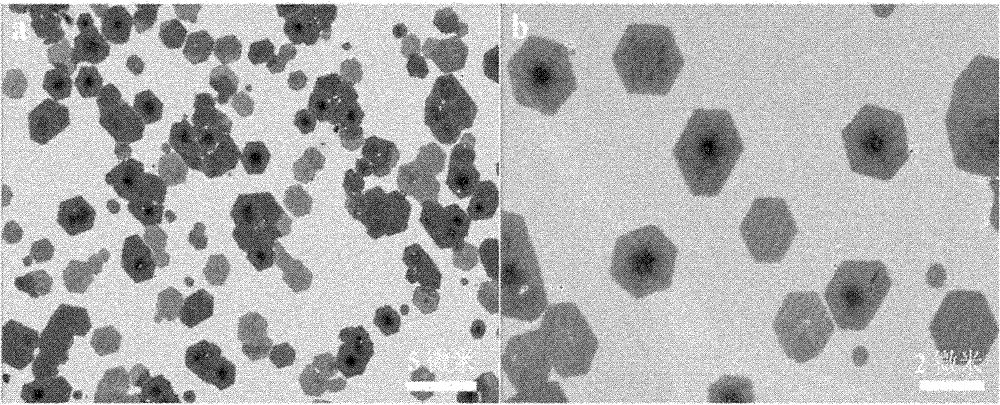

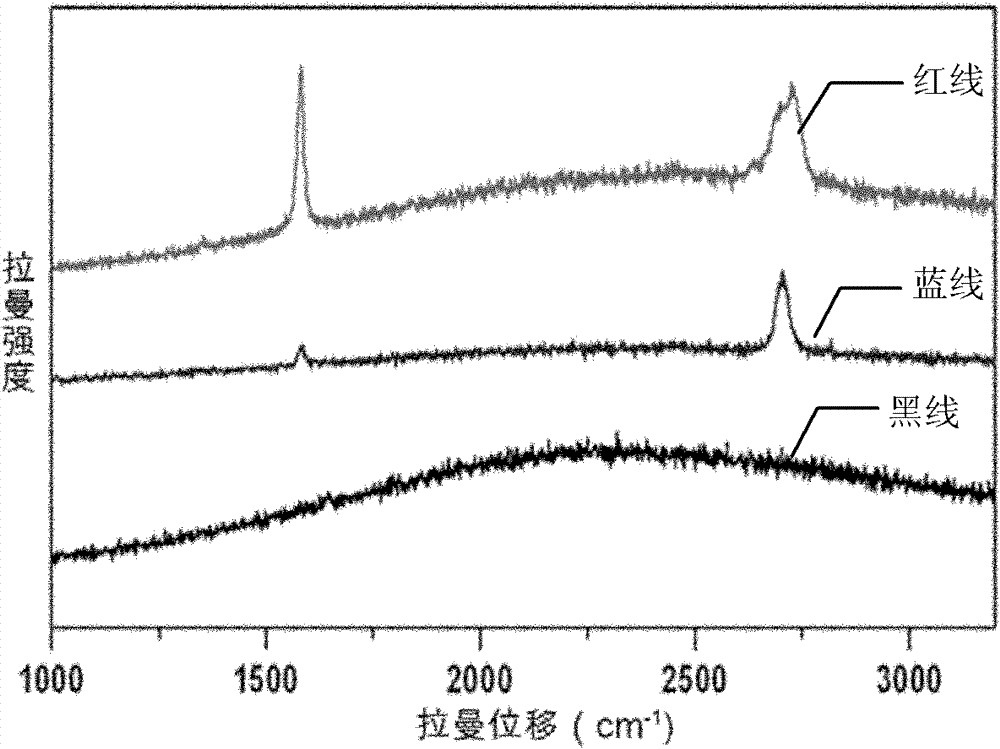

[0035] In the second step, the copper foil is placed in the middle of a clean quartz tube, and the quartz tube is put into an electric furnace so that the middle of the quartz tube is located in the central area of the electric furnace, and then 120 sccm of argon gas is passed into the quartz tube, 5 After ~10 minutes, the argon sparging was stopped. Turn on the vacuum pump to start vacuuming. When the pressure in the reaction chamber is 3 to 10 Pa, turn off the vacuum pump, and then feed the mixed gas of 100 sccm of argon and 300 sccm of hydrogen until the pressure in the reaction chamber is consistent with the external atmospheric pressure, and then stop feeding the argon. Only use 300sccm hydrogen as the carrier gas, and start heating after 10 minutes of vent...

Embodiment 2

[0039] Embodiment 2, preparation regular graphene

[0040] The preparation method is basically the same as in Example 1, except that when the electric furnace temperature reaches 1000° C., feed 20 sccm of methane as a carbon source, and the scanning electron micrograph of its product is as follows: Figure 7 As shown, the two-dimensional hexagonal structure can still be seen from the figure, but its shape begins to deviate from the ideal equiangular hexagonal structure. This fact is general, that is, the shape of graphene shifts toward more and more irregularity as the flow rate of the carbon source increases or, equivalently, the growth rate increases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com