Ceramic roller isostatic pressing process and special isostatic pressing equipment thereof

A ceramic roller, isostatic pressing technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of valves not being lubricated, unable to use water, poor wear resistance, etc., to reduce calcination energy consumption, reduce pollution, flow good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention are described in detail below.

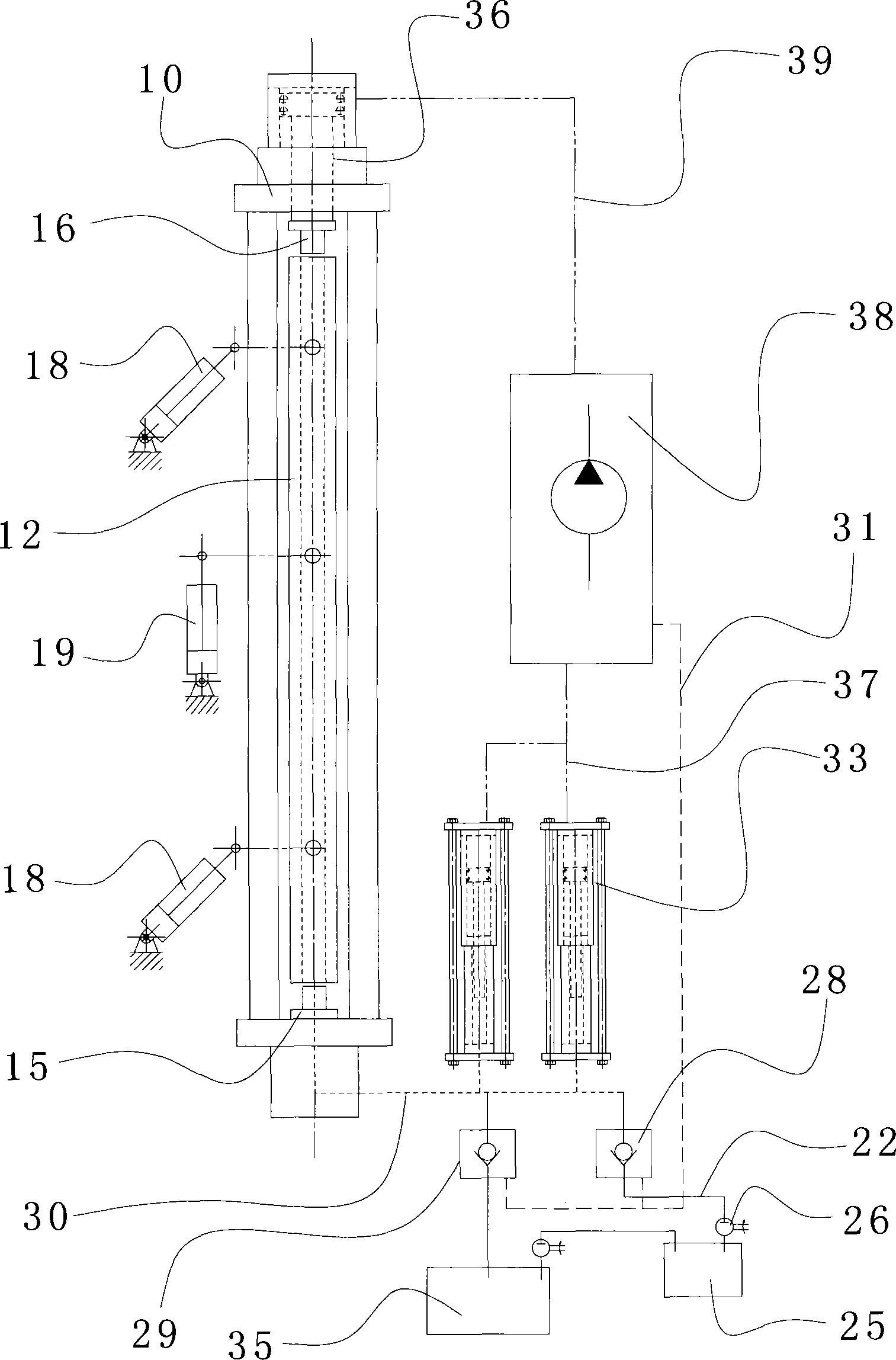

[0025] A method for isostatic pressing of ceramic roller rods. The outer body of the tubular body set on the inner mold of the rigid tube is covered with a waterproof rubber outer film, and it is placed in an autoclave as a whole workpiece to apply static high pressure. The pressure value is taken as 120Mpa or more, and then release the pressure and demould the tubular embryo body into the kiln for calcination.

[0026] Among them, in order to meet the length requirements of the current ceramic rollers without wasting equipment space, the current ceramic rollers are widely used with a length in the range of 4 meters to 7 meters. Therefore, the length of the autoclave should be taken as 4 meters or more. The more ideal length of the autoclave is 4-7m (inclusive), and the more ideal length is 6-7m (inclusive).

[0027] The autoclave in the present invention is high-pressure isostatic pressing equipment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com