Gradually-cutting type broach

An incremental cutting, cutting tool technology, applied in the field of layered metal cutting tools, to achieve the effects of stable pushing quality, easy replacement and short axial dimension

Active Publication Date: 2012-08-22

TAIZHOU LIHUA MACNINERY

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

During broaching, the cutting ability of the broach is directly proportional to the pulling force of the pulling broach. The slender rod-shaped broach bears limited pulling force, so broaching is only suitable for processing small modulus internal teeth with a small amount of cutting. For large modulus Due to the large amount of cutting to be cut, the inner ring gear needs to have enough length to share the cutting amount, so the designed broach is correspondingly lengthened, and the lengthening of the broach must require that the broaching machine has enough stroke matching, otherwise the production cannot be realized

The lengthening of the broaching machine not only increases the equipment cost, but also reduces the production efficiency due to the decrease of the tensile capacity of the extended broach

In general, the existing technology is not the best cutting method for mass production of ring gears

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0020]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

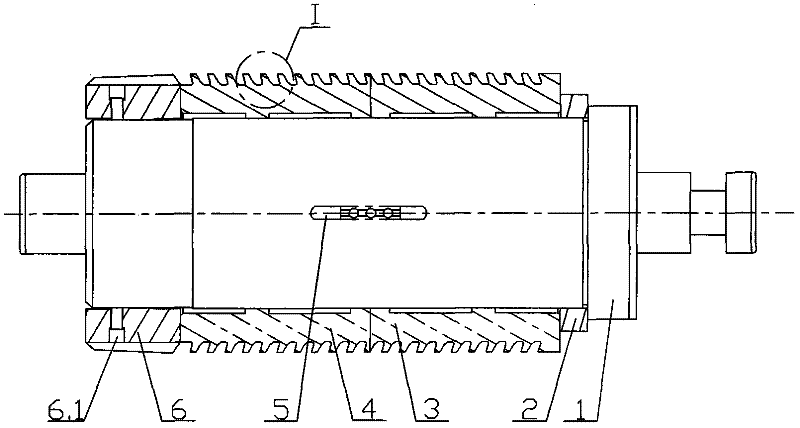

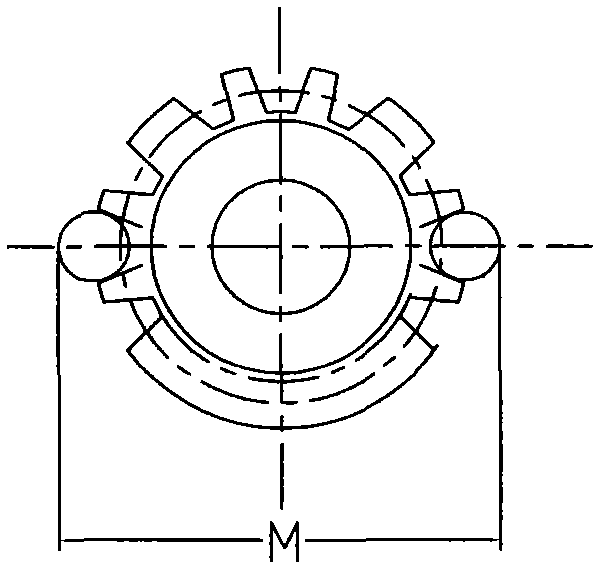

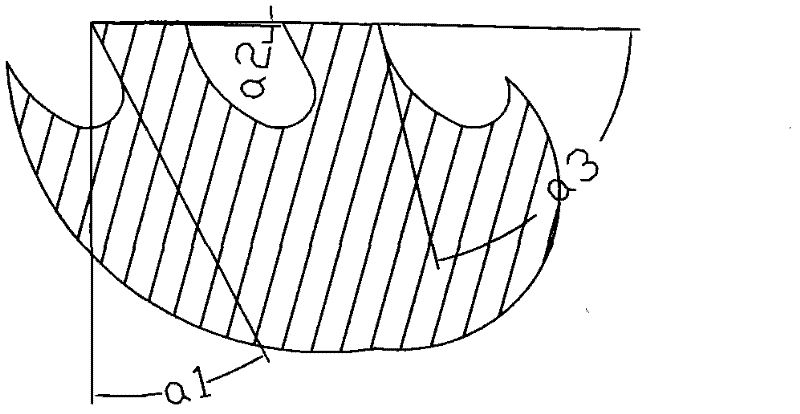

The invention discloses a gradually-cutting type broach which is a cylindrical tool formed by sequentially and serially sleeving a flat gasket, an upper tool body, a lower tool body and a locking ring by a central spindle provided with steps. The external diameter of the locking ring is equal to the internal diameter of an inner hole of a workpiece, the locking ring is in clearance fit with the workpiece, and locking screws matched with radial screw holes are uniformly distributed on the wall of the locking ring. The upper tool body and the lower tool body are of external conical tube shapes, and inner holes of the external conical tube shapes are in clearance fit with the central spindle and are in locating connection with the central spindle through flat keys. 20-40 tooth-shaped cutters with the distance of 13-15 mm are uniformly distributed on a upper cutter body and a lower cutter body cylindrical surface along the axial direction, the size differences of external diameters of the front and the back adjacent tooth-shaped cutters are between 0.02 mm and 0.18mm, and the size differences of external diameters of the tooth-shaped cutters on the same broach are equal. The gradually-cutting type broach has short axial size and good rigidity and is not easy to damage, and when cutting under the action of a thrust, the broach body can bear large cutting load, therefore, the cutting efficiency is high and the cutting quality is stable. By adopting a serially sleeved structure, the gradually-cutting type broach is easy to manufacture and realize high-precision manufacture and is particularly suitable for being used as a special tool for producing annular gears in batch.

Description

technical field [0001] The invention relates to a metal cutting tool, in particular, the invention relates to a tool capable of cutting metal in layers through straight-line pushing. Background technique [0002] The tooth portion of the inner ring gear is located on the inner wall, and this structural feature determines the manner in which the tooth portion is formed and cut. In the prior art, it is mainly manufactured by slotting or broaching. Traditional slotting technology is a common technology for internal gear forming cutting, but due to low production efficiency, it is not suitable for mass production of internal gear cutting. Broaching is more efficient than slotting, and has high manufacturing precision. At present, broaching is the most effective processing method for mass production of internal ring gears in the machinery manufacturing industry. During broaching, the cutting ability of the broach is directly proportional to the pulling force of the pulling broa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23F21/00

Inventor 顾往林

Owner TAIZHOU LIHUA MACNINERY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com