Method for preparing CNT/Fe3O4@ZnO one-dimensional nanocomposite by polyol one-pot method

A nanocomposite material and composite material technology are applied in the field of preparation of CNT/Fe3O4ZnO one-dimensional nanocomposite materials, which can solve the problem of no photocatalysis, and achieve the effects of being difficult to agglomerate, saving resources, and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

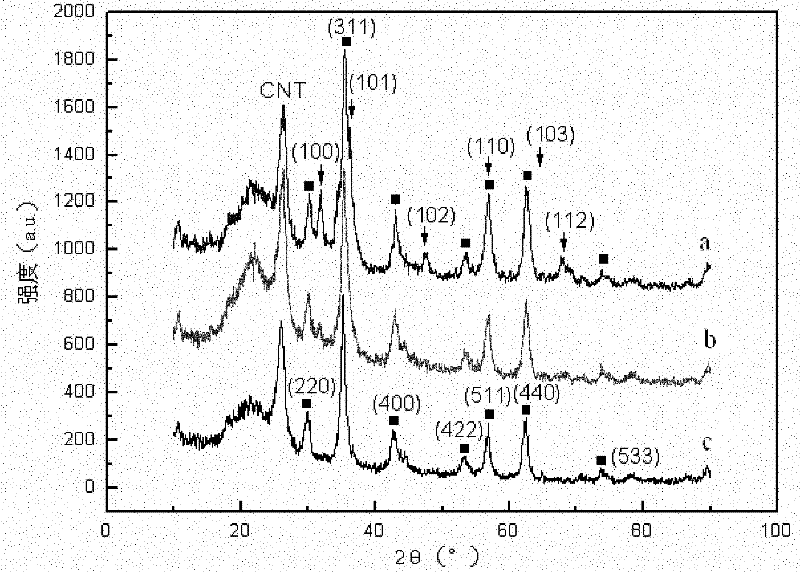

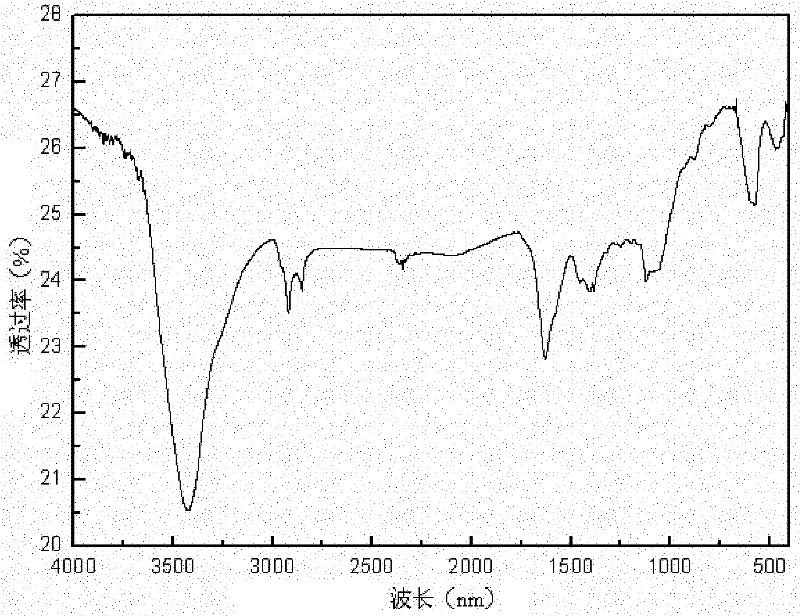

[0008] Specific implementation mode 1: In this implementation mode, polyalcohol one-pot method prepares CNT / Fe 3 o 4 The method of ZnO one-dimensional nanocomposite material is carried out as follows: one, take by weighing 100mg multi-walled carbon nanotube (one-dimensional matrix), 100~400mg iron acetylacetonate (precursor body) and 25ml triethylene glycol (solvent) After mixing, then ultrasonically disperse until it is uniform, then pass in argon gas, and then heat to the boiling point of triethylene glycol and reflux for 30-60 minutes; Glycol boiling point, reflux for 30-60 minutes, magnetically separate after cooling, wash with ethanol 4 times, and dry to obtain CNT / Fe 3 o 4 ZnO composite material.

specific Embodiment approach 2

[0009] Embodiment 2: This embodiment differs from Embodiment 1 in that the frequency of ultrasonic dispersion in Step 1 is 80 KHz.

specific Embodiment approach 3

[0010] Embodiment 3: This embodiment is different from Embodiment 1 in that: the heating rate in step 2 is 5° C. / min).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com