Preparation method and pressing device for radiation-oriented magnet ring or multipolar magnet ring

A radiation orientation, multi-pole magnetic ring technology, applied in the direction of inductance/transformer/magnet manufacturing, inorganic material magnetism, electrical components, etc., can solve the problem of uneven shrinkage of the magnetic ring, achieve magnetic uniformity, improve magnetic performance, The effect of increasing the degree of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] According to the present invention, the preparation method of radiation orientation magnetic ring and multi-pole magnetic ring comprises:

[0017] (1) Preparation of alloy ingots: the raw materials are conventionally smelted into alloy ingots in vacuum or inert gas;

[0018] (2) Alloy ingot crushing: coarsely crushing and hydrogen crushing the alloy ingot in an inert atmosphere to obtain a powder with a particle size of several hundred microns; add 0.01 to 1 wt% of an antioxidant to the hydrogen crushed powder to mix 2 Hours; use jet mill to pulverize the coarse powder after hydrogen crushing under nitrogen environment to obtain alloy powder with average particle size of about 4m and uniform particle size distribution;

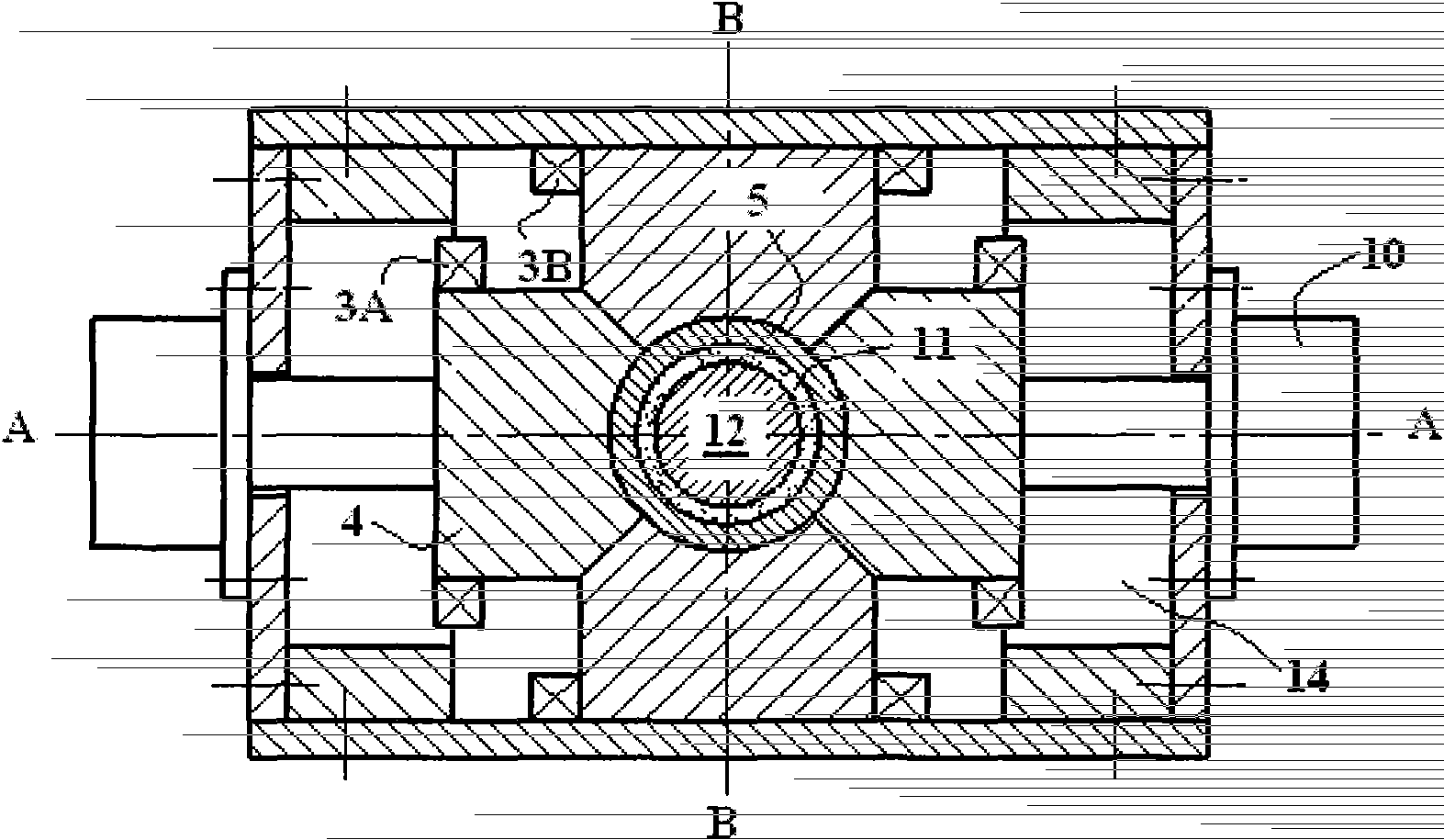

[0019] (3) Powder pre-orientation: Fill the powder into the mold cavity of the molding press, and perform pre-orientation operation on the powder; change the yoke to four movable parts along the circumferential direction, and move them separately during...

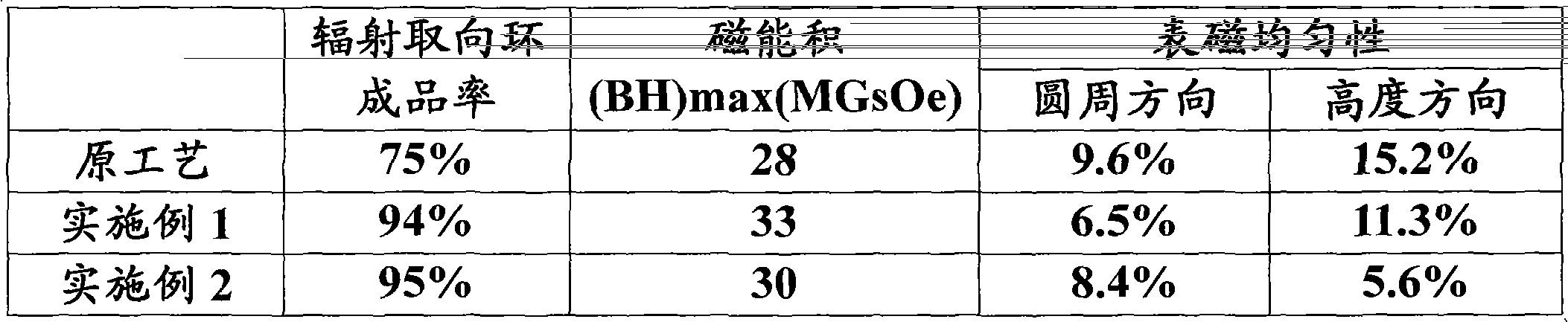

Embodiment 1

[0029] When powder is loaded, the two yokes 4 in the direction of length A-A and the two yokes 4 in the direction of width B-B form a complete ring. After the powder is loaded, the upper pressure head drops and the iron core closes. Move the two yokes 4 along the A-A direction for 50-150mm, and then, the excitation coil 3B generates a magnetic field with the same polarity along the B-B direction to pre-orient the powder for the first time, and the magnetic field in the mold cavity is 0.8-2.0T After the orientation is completed, push back the two yokes 4 in the direction of length A-A to their original positions; then move the two yokes 4 in the direction of width B-B for 50-150mm along the direction of B-B, and the excitation coil 3A generates a magnetic field with the same polarity , the direction is along the A-A direction, and the magnetic field in the mold cavity is 0.8-2.0T. After the orientation is completed, the yoke 4 in the width B-B direction is pushed back to the ori...

Embodiment 2

[0032] When powder is loaded, the two yokes 4 in the direction of length A-A and the two yokes 4 in the direction of width B-B form a complete ring. After the powder is loaded, the upper pressure head drops and the iron core closes. Pre-magnetize the pulsed magnetic field along the C-C direction (that is, the height direction), and then press the magnetic ring under the radiation orientation magnetic field.

[0033] In order to solve the cracking problem in the sintering process of the magnetic ring, after the radiation-oriented magnetic ring is pressed and isostatically pressed, it is placed in a protective gas atmosphere (such as an inert gas Ar 2 or N 2 ) or in a vacuum state, the inner wall of the magnetic ring is ground as a whole, and after the inner diameter is ground to 0.1-1 mm, the sintering aging heat treatment is performed.

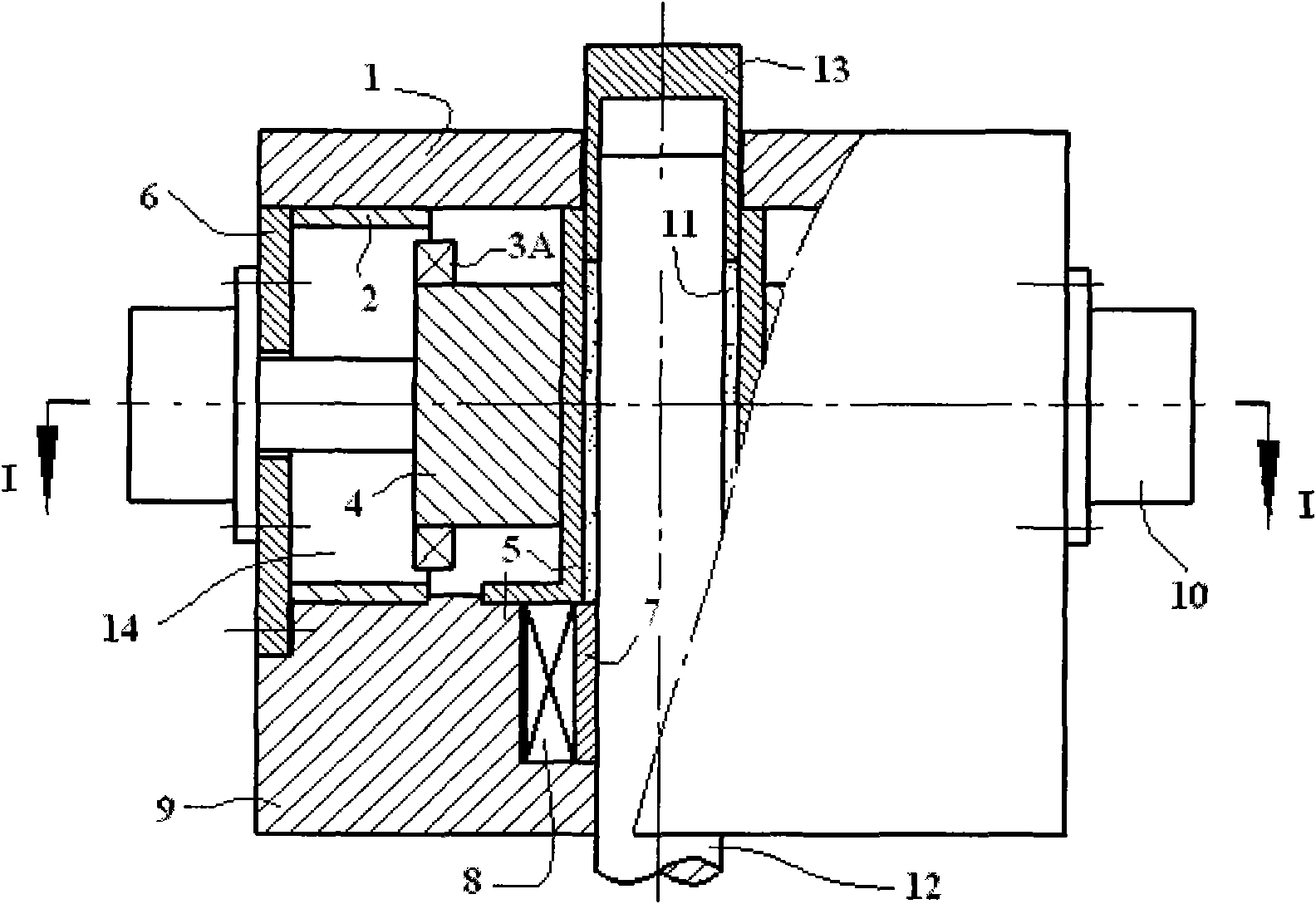

[0034] The present invention also provides a pressing device for preparing radiation-oriented magnetic rings and multi-pole magnetic rings. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com