Ring heat exchanger of sterling heat engine

A heat exchanger and annular technology, which is applied in the field of Stirling heat engine annular heat exchangers, can solve the problems that the cooler cannot be air-cooled, the heat exchange capacity is insufficient, and the production is difficult, so as to achieve sufficient space utilization and good heat exchange effect , reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

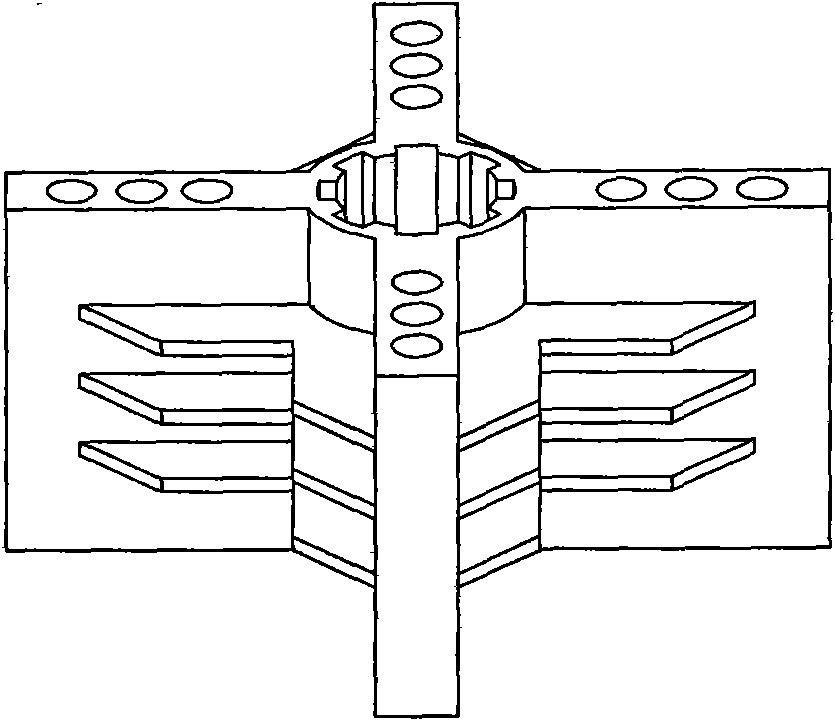

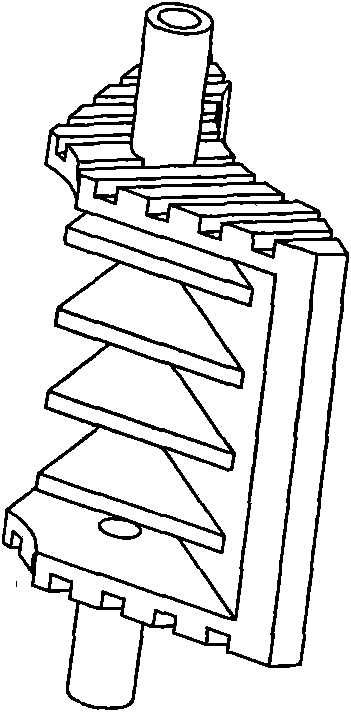

[0025] figure 1 The Stirling heat engine annular heat exchanger shown can be used as a heater and cooler for a Stirling reversible heat engine. As a heater, it is arranged in the middle of the four cylinders at the heat inflow end, the symmetrical center line coincides with the rotor axis of the heat engine, and the outer side is in contact with the cylinder surface. The four connecting pipes at one end of the heater communicate with the four cylinders at the heat inflow end respectively, and the four connecting pipes at the other end communicate with the four connecting pipes at one end of the regenerator respectively. As a cooler, it is arranged in the middle of the four cylinders at the heat outflow end, and the outside is in contact with the cylinder surface. The centerline of symmetry coincides with the axis of the rotor of the heat engine, and the rotor axis of the heat engine just passes through the central channel of the heat exchanger and is connected with the shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com